Automatic laminating device and method for positive and negative electrode plates of paper battery

A technology of positive and negative electrode sheets and lamination devices, which is applied in battery electrodes, electrode manufacturing, circuits, etc., can solve the problems that the finished product does not meet the requirements, is prone to lamination offset, and is inaccurate in lamination force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

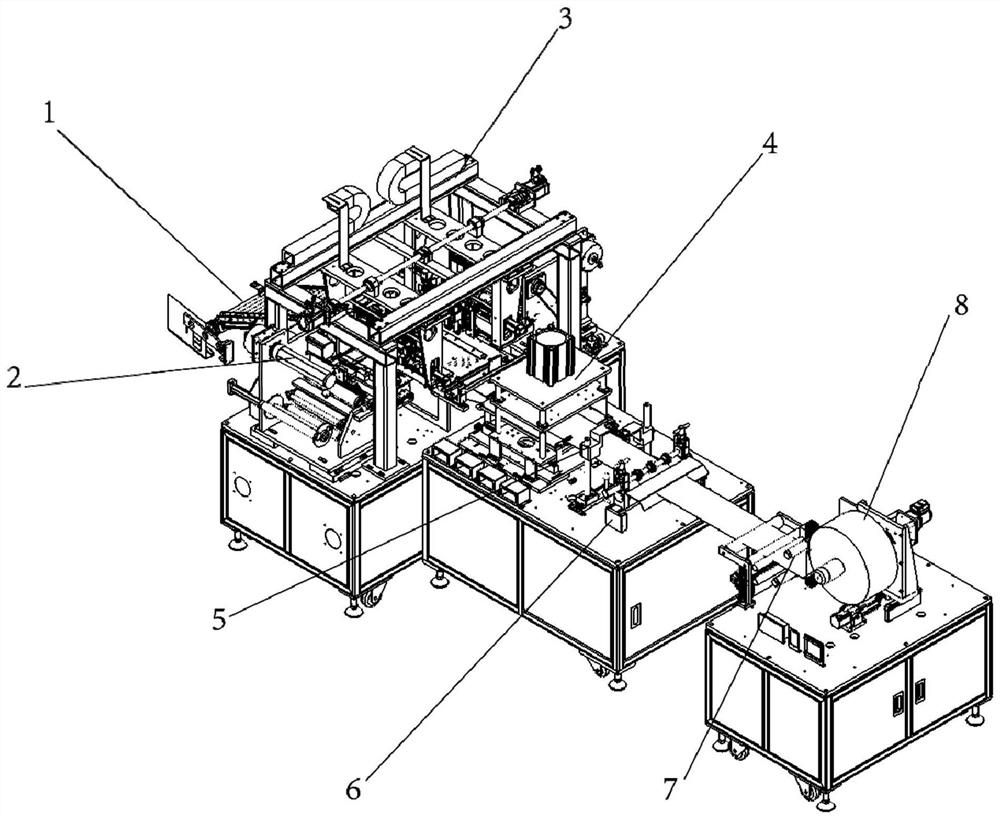

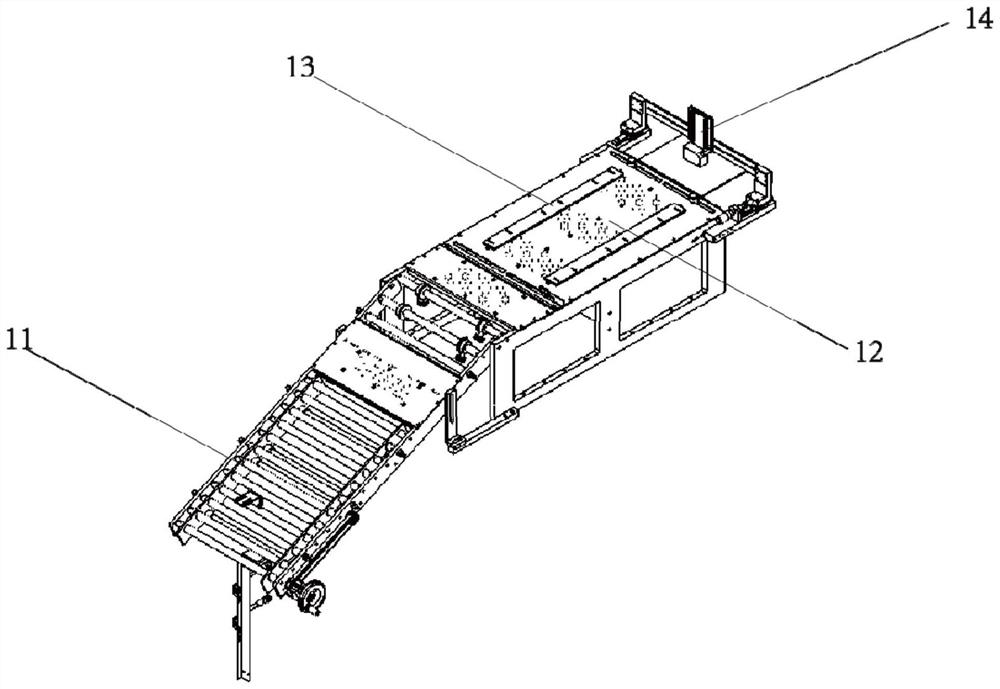

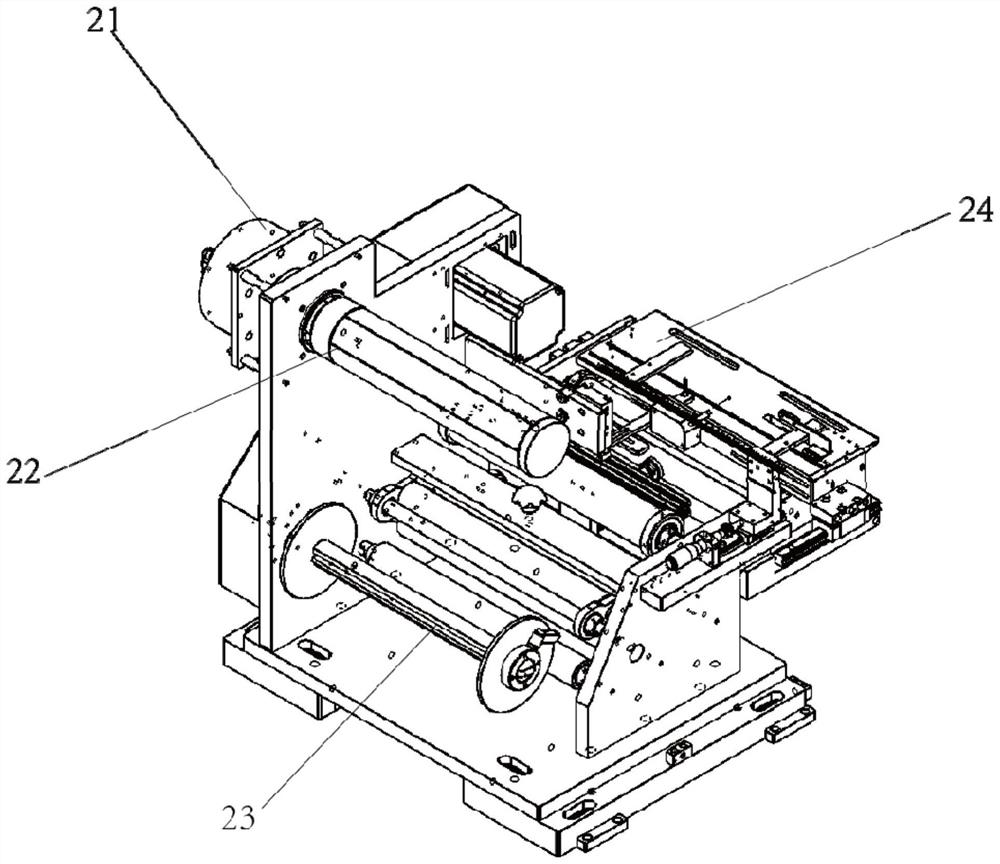

[0062] refer to Figure 1-10 ,in, figure 1 It shows a schematic structural view of an embodiment of an automatic bonding device for positive and negative sheets of a paper battery according to the present invention, which may specifically include:

[0063] Positive electrode unwinding part 1, negative electrode unwinding part, positive and negative electrode pressing part 4 and finished product rewinding part 8;

[0064] The positive electrode unwinding part 1 is arranged on the input side of the negative electrode unwinding part; the positive and negative electrode pressing part 4 is arranged on the output side of the negative electrode unwinding part; the finished product winding part 8 is arranged on the Describe the output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com