Composition for preparing electrode adhesive layer of automobile oxygen sensor and method for preparing electrode adhesive layer

The invention relates to a technology of an automobile oxygen sensor and a manufacturing method, which are applied in the field of the composition field for making an electrode adhesion layer of an automobile oxygen sensor, and can solve the problems of electrode shedding, low bonding strength, low bonding strength of the electrode layer, etc., and achieve uniform shrinkage and increase roughness. Degree, easy adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

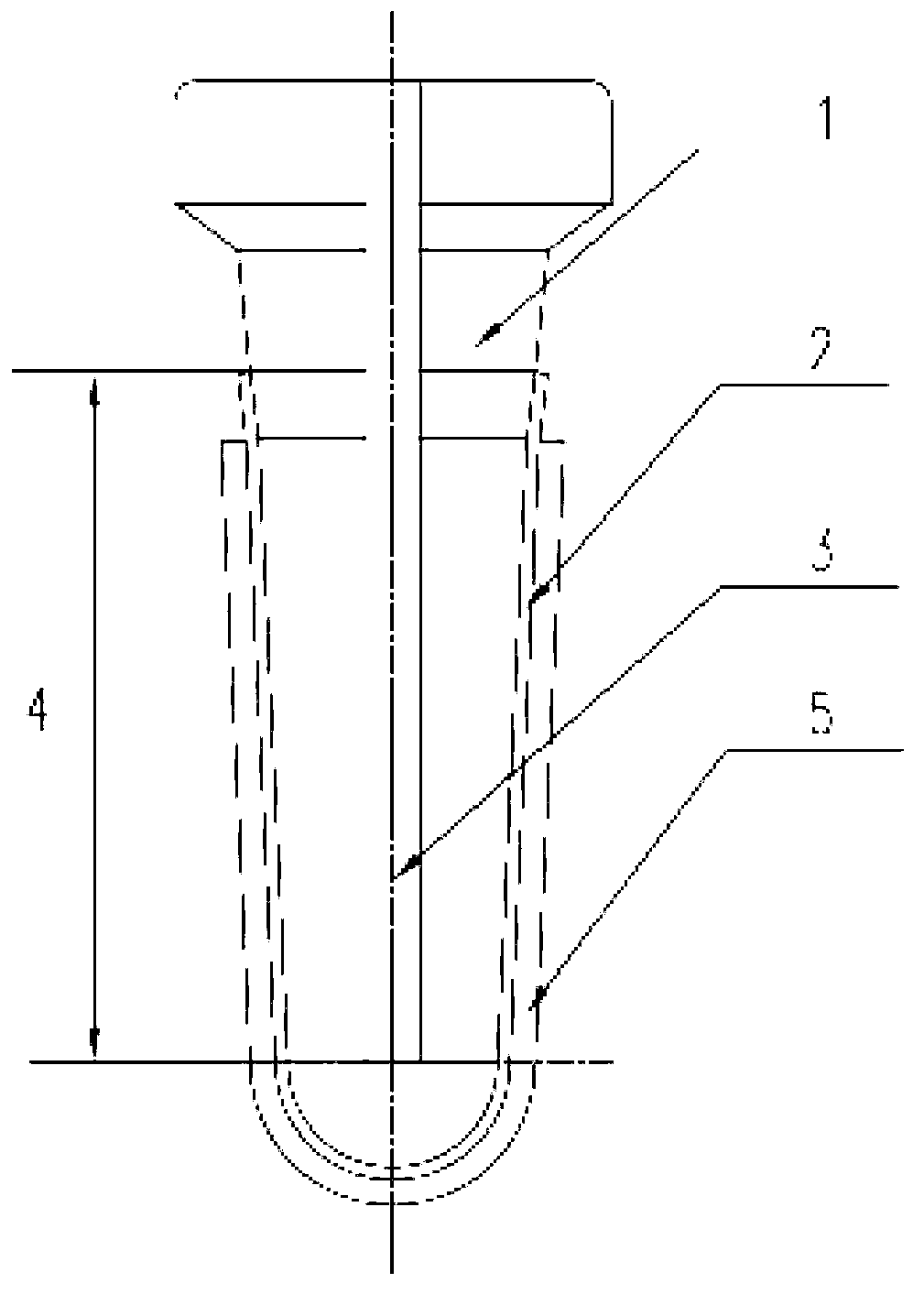

[0020] Mix 2wt% ethyl cellulose and 98wt% terpineol, and make it into a diluent by heating in a water bath. Put the molar ratio as Y 2 o 3 : ZrO 2 =2:98 ceramic powder and the prepared diluent are made into slurry according to the weight ratio of 1:1. Referring to the accompanying drawings, fix the zirconium tube blank 1 on the electric rotary tooling, use a brush to dip an appropriate amount of slurry and evenly coat a layer of slurry on the blank, and dry the coated area 4 in an oven at 60°C. The adhesion layer 2 is finished, and its thickness is 0.1 mm. Electrodes are then printed on the adhesive layer by pad printing. After the zirconium tube and the electrode are co-fired, the electrode layer 3 and the adhesion layer are closely combined with the zirconium tube body. When the electrode protective layer 5 is made by plasma spraying, the protective layer 5 is also easily attached to the electrode layer.

Embodiment 2

[0022] Mix 10wt% ethyl cellulose and 90wt% terpineol, and make it into a diluent by heating in a water bath. Put the molar ratio as Y 2 o 3 : ZrO 2 =5:95 ceramic powder and the prepared diluent are made into slurry according to the weight ratio of 1:1.5. Referring to the accompanying drawings, fix the zirconium tube blank 1 on the electric rotary tooling, dip a proper amount of slurry with a brush and evenly coat a layer of slurry on the blank, and dry the coated area 4 with a drying oven at 80°C. Dry, the adhesion layer 2 is finished, and its thickness is 0.2mm. Electrodes are then printed on the adhesive layer by pad printing. After the zirconium tube and the electrode are co-fired, the electrode layer 3 and the adhesion layer are closely combined with the zirconium tube body. When the electrode protective layer 5 is made by plasma spraying, the protective layer 5 is also easily attached to the electrode layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com