Preparation method for positive electrode of ternary power lithium ion battery and lithium ion battery

A lithium-ion battery and power technology technology, applied in the field of lithium-ion batteries, can solve the problems of lithium-ion battery energy density, power performance cycle performance cannot be satisfied, etc., and achieve high-rate fast charge and discharge, high ionic conductivity, and adhesion. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

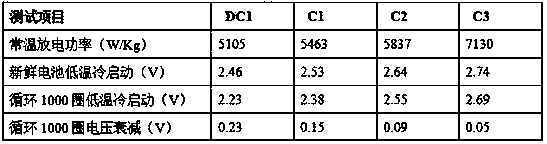

Examples

specific Embodiment approach 1

[0011] Specific Embodiment 1: This embodiment records a method for preparing the positive electrode of a ternary power lithium-ion battery. Adhesive and NMP, stir and disperse evenly at a revolution speed of 20~60rpm, and a dispersion disc speed of 200~2000rpm, adjust the revolution speed to 10~30rpm, take the material and measure the solid content (the purpose of measuring the solid content is to confirm the actual feeding of the process and the theoretical solid content) If there is any abnormality, you can control the solid content of the slurry within a reasonable range by adjusting the amount of solvent), and turn on the vacuum pump to keep the vacuum at -0.08~-0.09MPa , after stirring for 30 minutes, release the vacuum to obtain the positive electrode slurry, and apply the obtained positive electrode slurry on the positive electrode current collector to obtain the positive electrode. The method may also include: passing the obtained positive electrode slurry through a 20...

specific Embodiment approach 2

[0012] Specific embodiment two: the preparation method of a positive electrode of a ternary power lithium ion battery described in specific embodiment one, the described ternary NCM is a high-power type NCM or a high-energy type NCM; the described high-power type NCM is NCM111 or NCM622, the particle size is D10 1.0~3.8μm, D50 4.0~8.0μm, D90 ≤17μm; the high-energy NCM is one of NCM523, NCM622, NCM811 or NCA.

specific Embodiment approach 3

[0013] Specific embodiment three: the preparation method of a positive electrode of a ternary power lithium-ion battery described in specific embodiment one, the positive electrode binder is PVDF series or acrylic ester; the PVDF series is polyvinylidene fluoride 5130 or polyvinylidene fluoride 900, the acrylates are polybutyl acrylate, polymethyl methacrylate or cyanoacrylate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com