Electrode of metal powder substrate inductor and preparation method of electrode

A metal powder and inductor technology, applied in the manufacture of inductors/transformers/magnets, chemical instruments and methods, transformers/inductor coils/windings/connections, etc., can solve the problem that inductors are not easily resistant to high temperatures and the production cost of inductors increases , Damage to the inductor body and other issues, to achieve the effect of enhancing installation reliability, improving electrode adhesion, and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

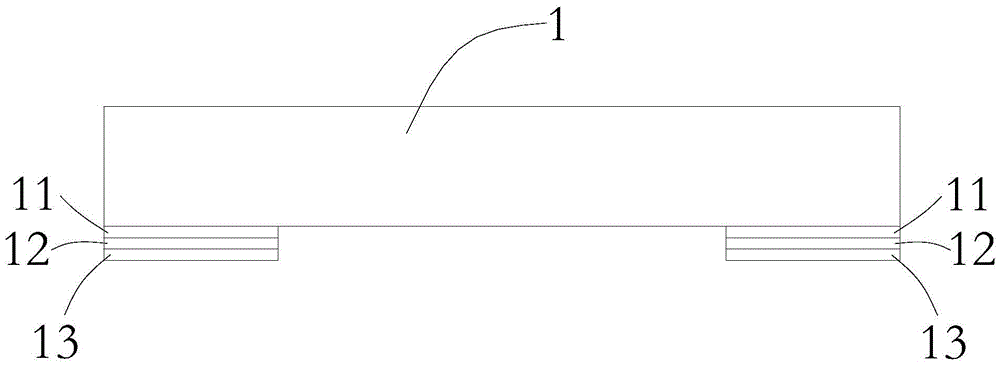

[0027] This embodiment provides an electrode of a metal powder matrix inductor, such as figure 1 As shown, it is arranged at the electrode of the inductor 1, and the electrode includes a base layer 11, a conductive layer 12 and a tin layer 13 stacked on the electrode in sequence, wherein the base layer 11 is provided by electroplating at the electrodes.

[0028] The base layer 11 is a conductive metal layer, such as zinc, copper, nickel or silver layer, preferably copper.

[0029] The conductive layer 12 can be a conductive metal layer, such as copper, nickel or silver layer; it can also be a conductive alloy layer, such as nickel-chromium alloy or copper-tin alloy.

[0030] The conductive layer 12 can be one layer, or multiple layers stacked.

Embodiment 2

[0032] This embodiment provides a method for preparing the electrode of the metal powder matrix inductor described in Embodiment 1, which includes the following steps:

[0033] Mask all or part of the inductor (including electrodes and non-electrodes);

[0034] Remove the mask at the electrode at the bottom, so that the bottom of the inductor is not exposed except for the electrode, and only the electrode is exposed;

[0035] electroplating a base film 11 at the electrodes;

[0036] A conductive layer 12 and a tin layer 13 are sequentially prepared on the surface of the base film 11 .

[0037] The conductive layer 12 can be a conductive metal layer, such as copper, nickel or silver layer; it can also be a conductive alloy layer, such as nickel-chromium alloy or copper-tin alloy.

[0038] The base layer 11 is a conductive metal layer, such as: zinc, copper, nickel or silver layer;

[0039] The conductive layer 12 can be one layer, or multiple layers stacked.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com