Composite pole and battery module with same

A technology of battery modules and poles, which is applied in the field of battery modules, can solve problems such as difficult welding and easy occurrence of welding places, and achieve the effects of good interface resistance, avoid welding, and small composite interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

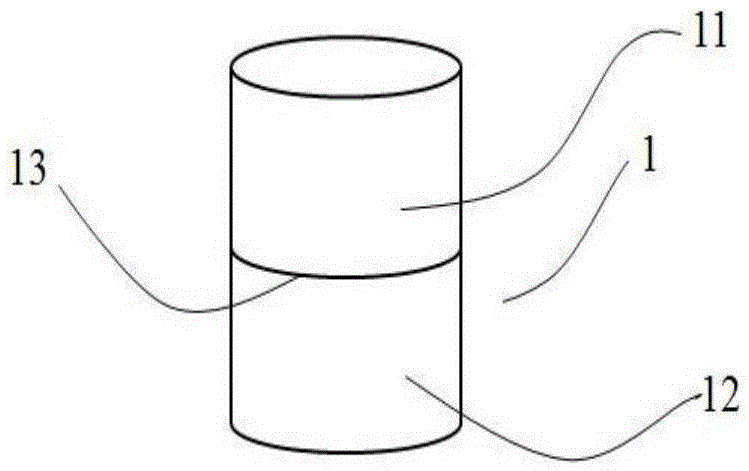

[0034] like figure 1 As shown, the present embodiment provides a composite pole. The composite pole 1 includes a first end 11 and a second end 12 made of different metal materials; The outer conductor 4 is made of the same metal material.

[0035] The composite pole 1 provided in this embodiment includes a first end 11 and a second end 12 made of different metal materials, and the end connected to the outer conductor 4 is made of the same metal material as the outer conductor 4 ; Therefore, the welding between the same metals does not have the difficulty of dissimilar metal welding during the welding process, and is easier to operate than dissimilar metal welding.

[0036] Specifically, the first end 11 is made of copper material, and the second end 12 is made of aluminum material; when the outer conductor 4 is made of copper material, the first end of the composite pole 1 One end 11 is directly connected to the outer conductor 4; when the outer conductor 4 is made of alumin...

Embodiment 2

[0042] On the basis of Example 1, this example further provides a method for preparing the above-mentioned composite pole 1;

[0043] a. Explosive composite method or diffusion welding or friction welding or brazing or rolling composite method or hot-melt rolling method will be used to prepare two different metal materials for the first end 11 and the second end 12 Made into one body to obtain a composite board;

[0044] b. Level the composite board;

[0045] c. Cutting or punching out the composite pole along the direction perpendicular to the composite plate.

[0046] As a preferred embodiment, the composite board is prepared by explosive composite method; specifically, when preparing the composite board, the doubler board is first placed on the substrate, and then a layer of explosive is laid on the doubler board to utilize the explosion generated by the explosive The instantaneous ultra-high pressure and ultra-high-speed impact realize the solid-state metallurgical bondi...

Embodiment 3

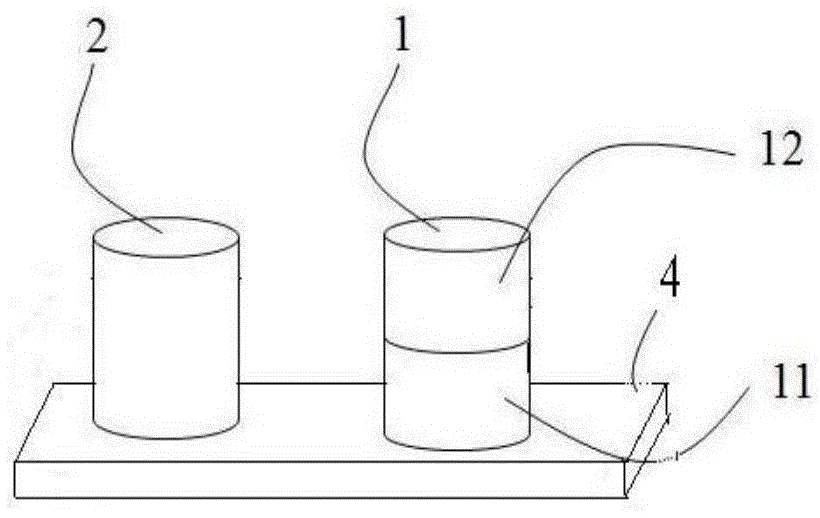

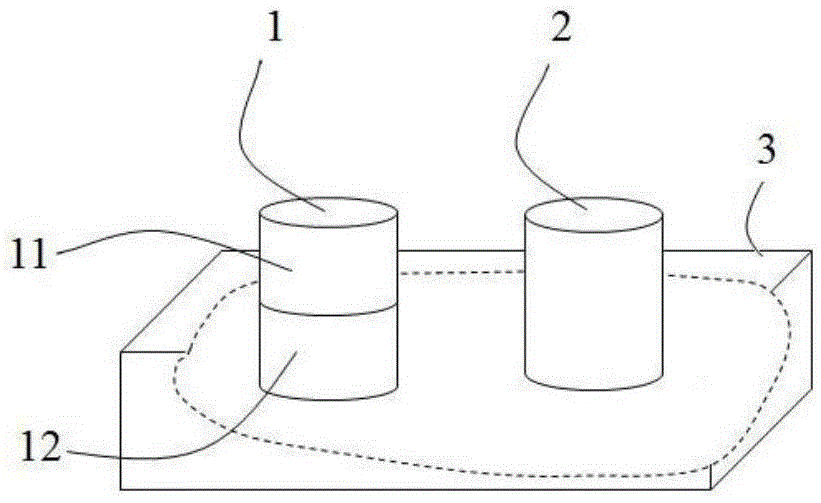

[0050] like figure 2 As shown, on the basis of the above embodiments, this embodiment further provides a battery module, including several single cells 3, and the electrode terminals between two adjacent single cells 3 are connected through external conductors 4, The electrode terminal includes a conventional pole 2, and a negative / positive pole composed of the composite pole 1 as described above; wherein, the metal material used at the end of the composite pole 1 connected to the external conductor is the same as The conventional pole 2 and the outer conductor 4 are made of the same metal material. Wherein, in this embodiment, the composite pole 1 , the conventional pole 2 and the outer conductor 4 are connected by welding; meanwhile, the outer conductor 4 can also be covered with a layer of nickel.

[0051] In this embodiment, the electrode terminals of the battery module include a positive pole / negative pole formed by a conventional pole 2, and a negative pole / positive po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com