Non-stress-connection wrapping connection type wire clamp of electric wires

A technology of power wires and wire clamps, which is applied in the field of power wire connection devices, can solve the problems of large material differences between wire clamps and wires, difficulty in moving, and rapid electrical corrosion, etc., and achieves convenient installation and disassembly operations, firm wrapping connections, and safe connections reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

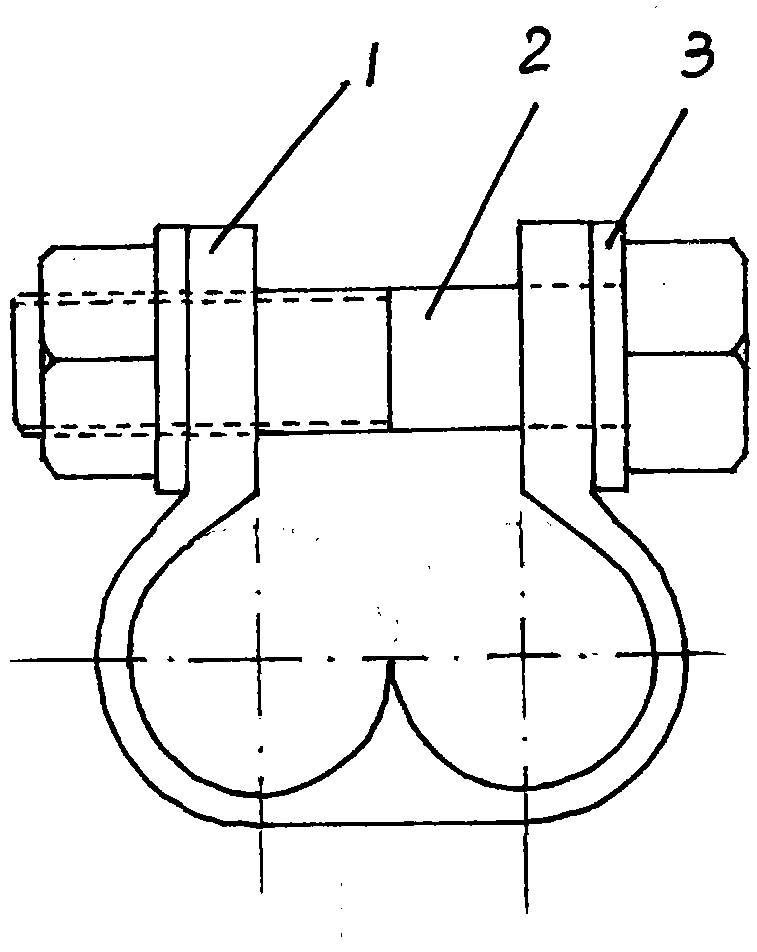

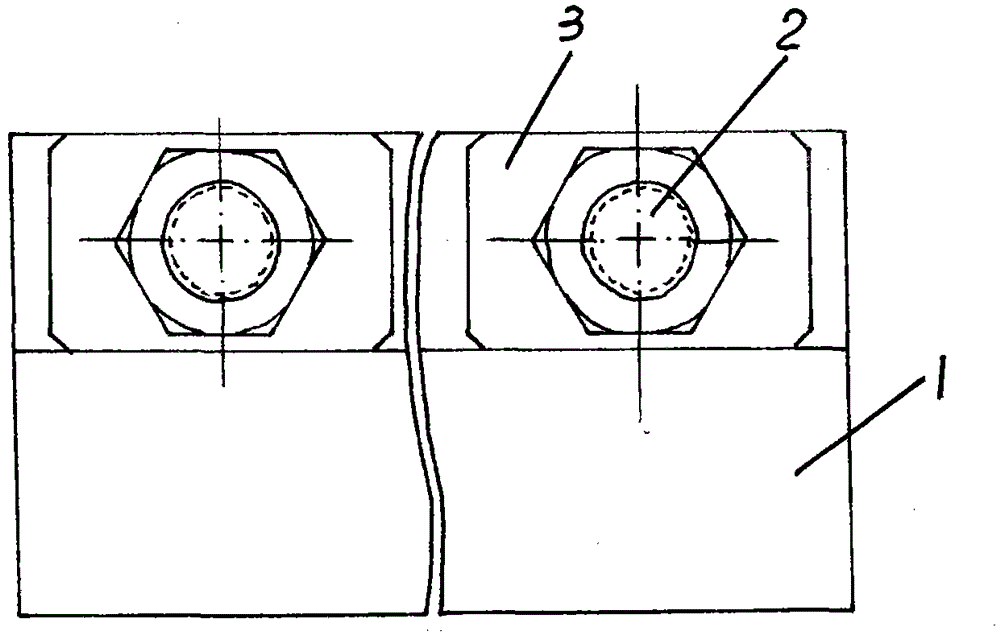

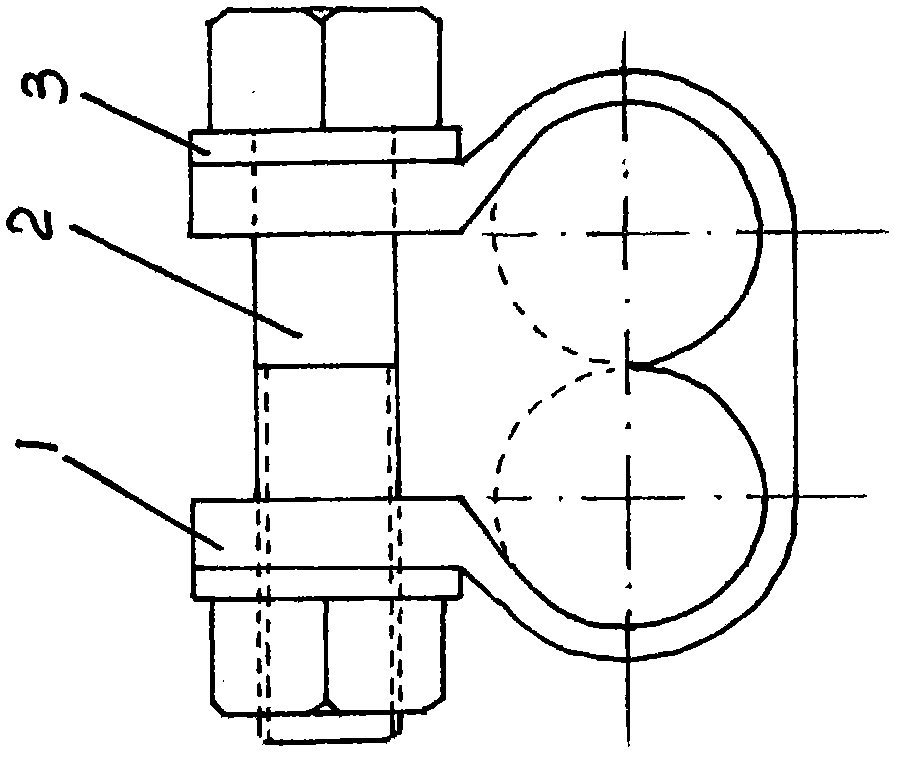

[0019] Figure 1-3 Shown: a wrap-around clamp for unstressed connection of power conductors, consisting of a clamp body 1 and a fastener assembly 2. The clamp body 1 is an elongated groove with a "U" shape in cross section, and a fastener assembly 2 is installed transversely on the upper opening of the "U" shape of the clamp body 1, and the "U" at the lower part of the clamp body 1 The cross-section of the inner wall of the zigzag wire clip body is in the shape of "ω". The "ω" shape of the "U"-shaped inner wall of the lower part of the clamp body 1 is formed by the intersection of two semicircular arc walls on the inner wall of the lower part of the clamp body 1. The two semi-arc wall bodies are circular arcs of 180-270 degrees symmetrically arranged on the left and right, and the two arcs are arranged on the left and right sides of the lower part of the clamp body 1, and the two arcs are arranged on the lower part of the clamp body 1. cavity and intersect. The two circular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com