Non-enzymatic biosensor based on carbon material/boron-doped diamond composite electrode as well as preparation method and application of non-enzymatic biosensor

A boron-doped diamond and biosensor technology, applied in the field of non-enzyme biosensor preparation, can solve the problems of poor repeatability of sample preparation, high preparation cost, poor combination of nano-sensitive materials and carriers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

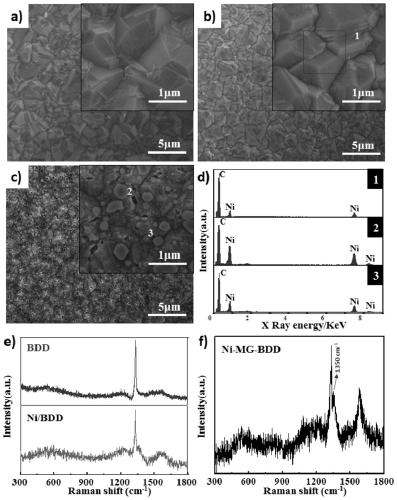

[0039] Step 1, silicon substrate pretreatment. First place the silicon substrate in an acetone solution for 10 minutes of ultrasonic treatment to remove surface oil; then place it in nano-diamond seed crystal suspension for 30 minutes to increase the nucleation rate of diamond growth; finally place it in anhydrous Sonicate in ethanol for 5 minutes;

[0040] Step 2, preparation of boron-doped diamond film. Hot wire chemical vapor deposition of boron-doped diamond is adopted. During the deposition process, the reaction gas is fed into and includes hydrogen, methane, and borane. The hydrogen flow rate is 98 sccm, the methane flow rate is 2 sccm, and the borane flow rate is 0.4 sccm. The filament temperature is 2500-2700°C, the deposition temperature is 800-850°C, the deposition pressure is 3kPa, and the deposition time is 12h.

[0041] Step 3, preparation of the nickel catalyst layer. A nickel layer is deposited on the surface of boron-doped diamond by magnetron sputtering. In...

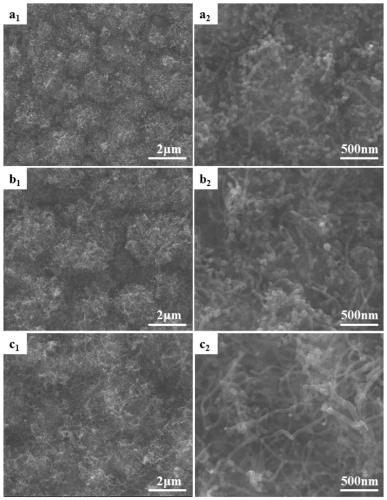

Embodiment 2

[0045] Step 1, silicon substrate pretreatment. First place the silicon substrate in an acetone solution for 10 minutes of ultrasonic treatment to remove surface oil; then place it in nano-diamond seed crystal suspension for 30 minutes to increase the nucleation rate of diamond growth; finally place it in anhydrous Sonicate in ethanol for 5 minutes;

[0046] Step 2, preparation of boron-doped diamond film. Hot wire chemical vapor deposition of boron-doped diamond is adopted. During the deposition process, the reaction gas is fed into and includes hydrogen, methane, and borane. The hydrogen flow rate is 98 sccm, the methane flow rate is 2 sccm, and the borane flow rate is 0.4 sccm. The filament temperature is 2500-2700°C, the deposition temperature is 800-850°C, the deposition pressure is 3kPa, and the deposition time is 12h.

[0047] Step 3, preparation of the nickel catalyst layer. A nickel layer is deposited on the surface of boron-doped diamond by magnetron sputtering. In...

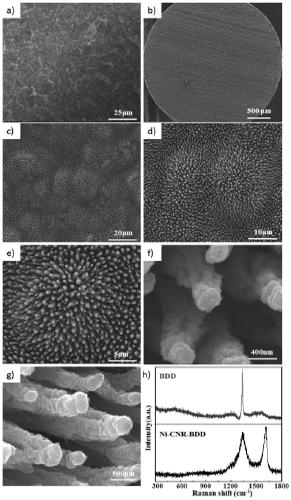

Embodiment 3

[0051] Step 1, silicon substrate pretreatment. First place the silicon substrate in an acetone solution for 10 minutes of ultrasonic treatment to remove surface oil; then place it in nano-diamond seed crystal suspension for 30 minutes to increase the nucleation rate of diamond growth; finally place it in anhydrous Sonicate in ethanol for 5 minutes;

[0052] Step 2, preparation of boron-doped diamond film. Hot wire chemical vapor deposition of boron-doped diamond is adopted. During the deposition process, the reaction gas is fed into and includes hydrogen, methane, and borane. The hydrogen flow rate is 98 sccm, the methane flow rate is 2 sccm, and the borane flow rate is 0.4 sccm. The filament temperature is 2500-2700°C, the deposition temperature is 800-850°C, the deposition pressure is 3kPa, and the deposition time is 12h.

[0053] Step 3, preparation of the nickel catalyst layer. A nickel layer is deposited on the surface of boron-doped diamond by magnetron sputtering. In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com