Nitrogen vacancy and hydroxyl synergistically modified graphite-phase carbon nitride photocatalyst as well as preparation and application thereof in photocatalytic hydrogen production

A photocatalyst, nitrogen vacancy technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen, etc., can solve the problems of reducing the band gap value and increasing the light absorption capacity, so as to reduce the band gap value and easily capture the empty space. the effect of reducing the recombination efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

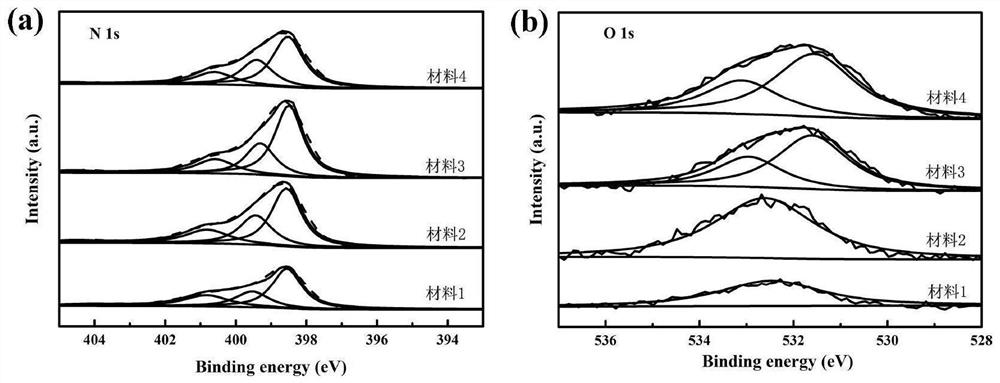

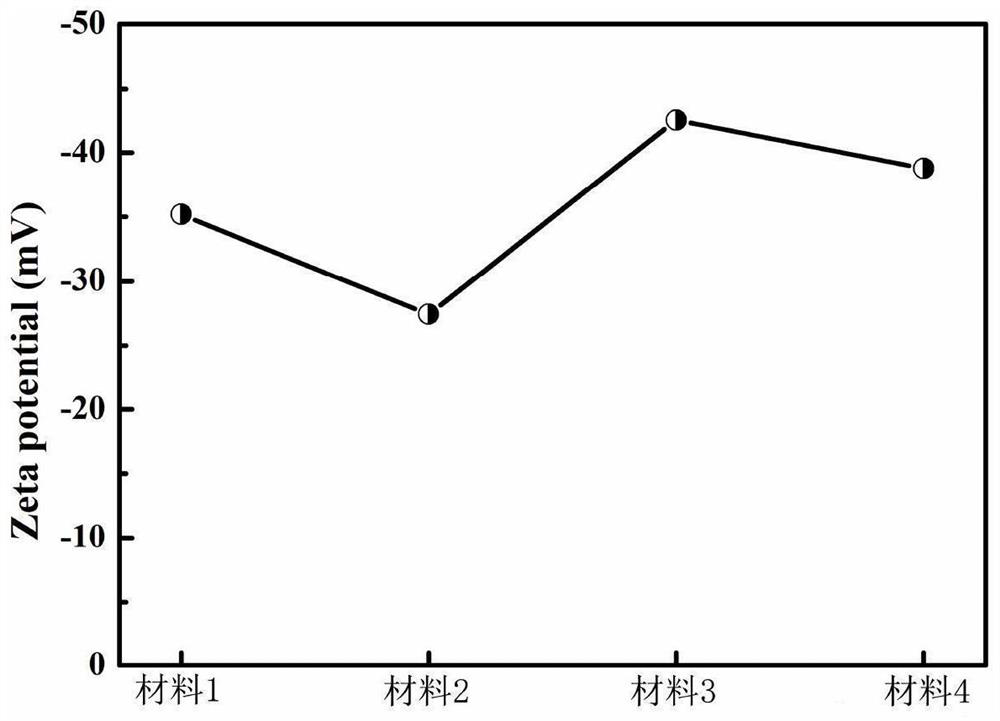

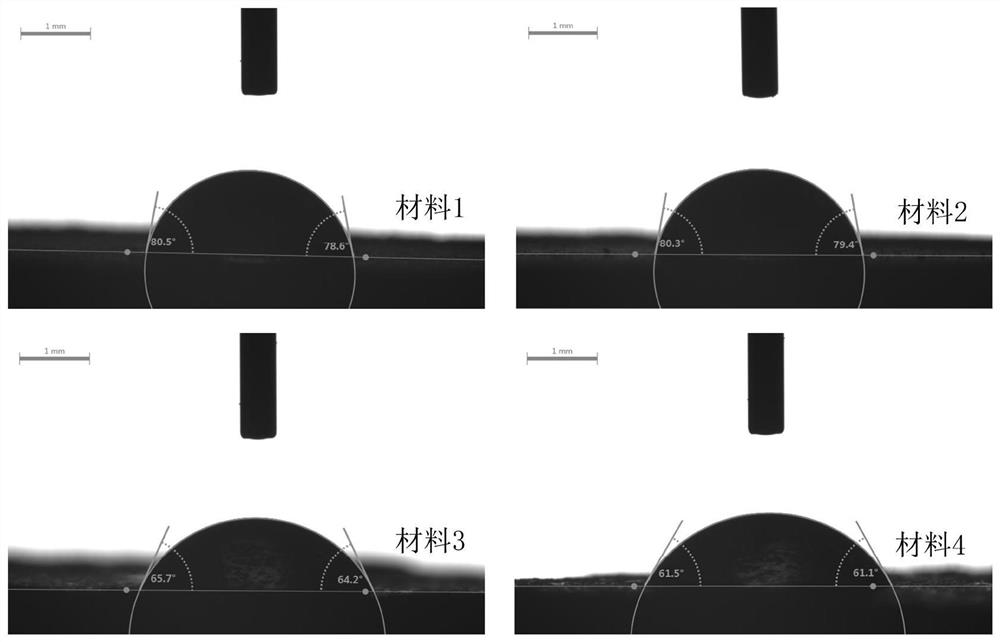

[0037] Put 1 g of melamine in a covered crucible and calcinate at 550°C for 4 hours at a heating rate of 2.3°C / min. After cooling to room temperature, wash with water and alcohol for three times to collect the precipitate, and dry it in an oven at 60°C for 12 hours to obtain the basic g-C 3 N 4 Photocatalytic material 1.

Embodiment 2

[0039] Grind and mix 1g of melamine with 7wt.% oxalodihydrazine, then place it in a covered crucible and calcinate at 550°C for 4h at a heating rate of 2.3°C / min, after cooling to room temperature, wash with water and alcohol for three times to collect the precipitate , dried in an oven at 60°C for 12 hours to obtain nitrogen vacancy modified g-C 3 N 4 Photocatalytic material 2.

Embodiment 3

[0041] Put 1 g of melamine in a covered crucible and calcinate at 550 °C for 4 h at a heating rate of 2.3 °C / min. After cooling to room temperature, wash with water and alcohol for three times to collect the precipitate, and dry it in an oven at 60 °C for 12 h. The dried powder is transferred to a 50mL high-pressure reactor with a stainless steel substrate, and 35mL of dilute ammonia is added in the reactor. The mass percentage of ammonia is 1%. After ultrasonication in an ultrasonic machine for 30 minutes, the Transfer the reaction kettle to an oven at 160°C for 4 hours. After cooling to room temperature, wash with water and alcohol for three times to collect the precipitate, and dry it in an oven at 60°C for 12 hours to obtain hydroxyl-modified g-C 3 N 4 Photocatalytic materials3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com