Separator for lithium secondary battery having enhanced electrode adhesive strength and improved resistance characteristics, and

A lithium secondary battery and separator technology, applied in secondary batteries, lithium storage batteries, non-aqueous electrolyte storage batteries, etc., can solve problems such as unfavorable adhesion and unfavorable resistance, increase adhesion surface area, improve interface resistance, improve Effects of Output and Lifetime Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0098] Preparation of Porous Coating Forming Composition

[0099] As inorganic particles, prepared Al-containing particles with an average diameter of 500nm 2 o 3 A mixture of powder and γ-AlOOH powder (weight ratio 9:1) with an average diameter of 250 nm.

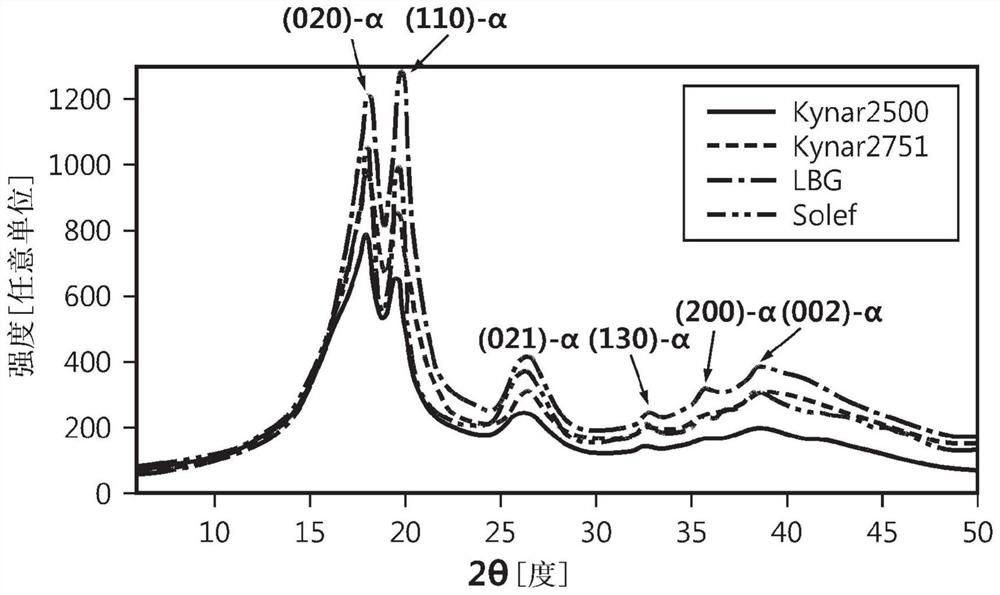

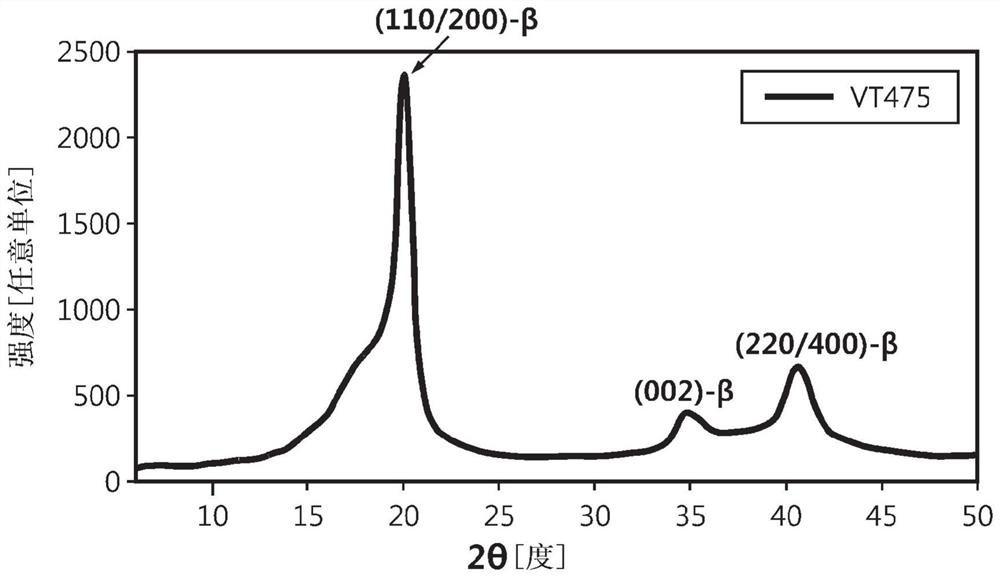

[0100] As the binder polymer, two types of PVdF-based binder polymers were prepared, among which PVdF-HFP binder polymer (Solvay Company, Solef 21510) was prepared as the first PVdF-based binder polymer, Also, a PVdF-TFE binder polymer (Daikin Corporation, VT-475) was prepared as a second PVdF-based binder polymer.

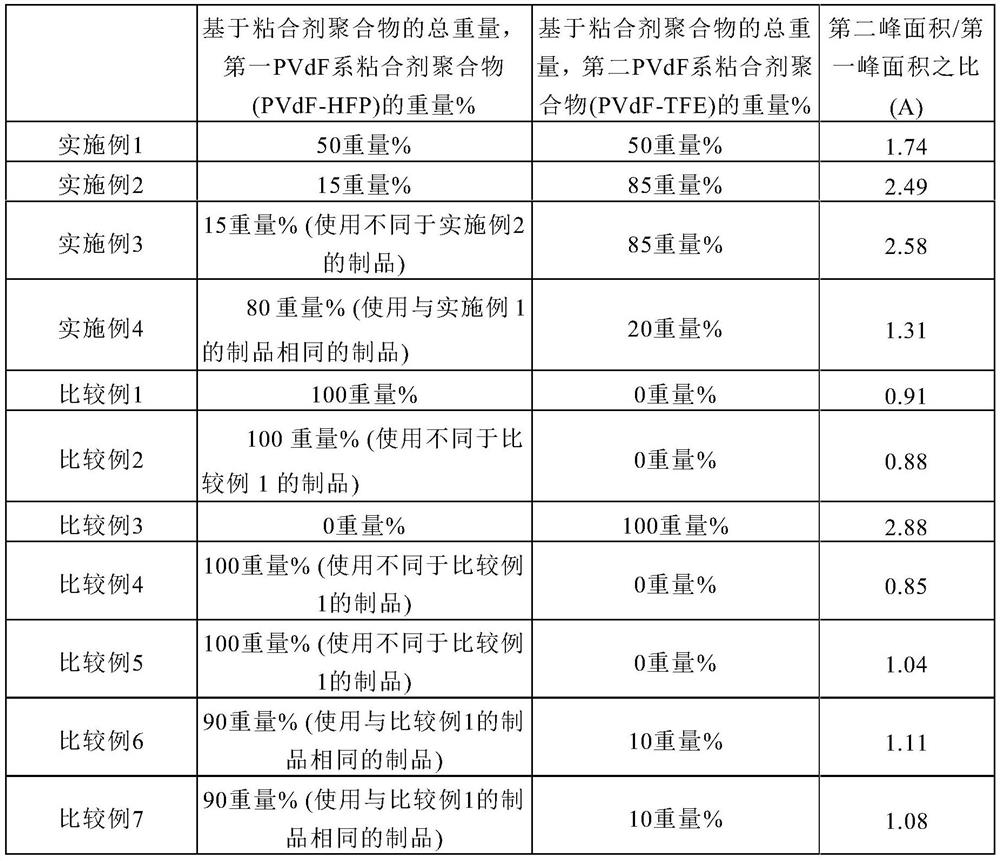

[0101] The first PVdF-based binder polymer and the second PVdF-based binder polymer were mixed at a weight ratio of 1:1, and the resulting mixture was dissolved in N-methylpyrrolidone (NMP ) for about 4 hours to prepare the binder polymer solution.

[0102] The mixed inorganic particles were added to the binder polymer solution at a weight ratio of binder polymer:mixed inorganic particles of 35:65.

[0...

Embodiment 2

[0109] A separator for a lithium secondary battery was obtained in the same manner as in Example 1, except that the PVdF-HFP binder polymer pair as the first PVdF-based binder polymer was polymerized as the second PVdF-based binder The weight ratio of PVdF-TFE binder polymer was changed to 15:85.

Embodiment 3

[0111] A separator for a lithium secondary battery was obtained in the same manner as in Example 1, except that the PVdF-HFP binder polymer as the first PVdF-based binder polymer was changed to Kynar 2500 available from Arkema Corporation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com