Separator, having improved electrode adhesion and resistance property, for lithium secondary battery, and lithium secondary battery comprising same separator

A lithium secondary battery and separator technology, which is applied in the field of lithium secondary batteries, can solve the problems of different phase separation rates, increased process complexity, uneven pore structure and distribution of adhesive polymers, etc., to improve gas permeability , Improvement of output and life characteristics, effect of low interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

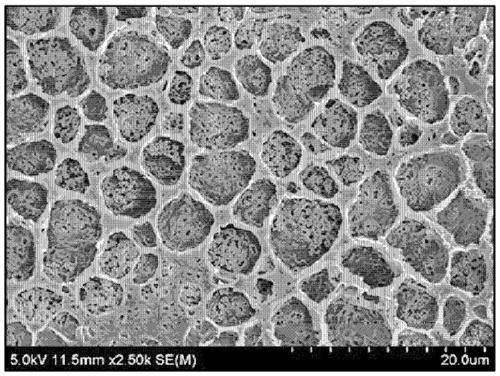

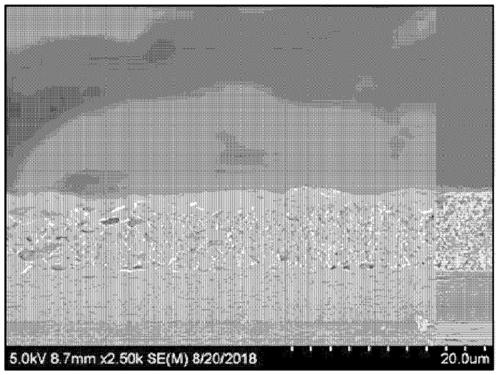

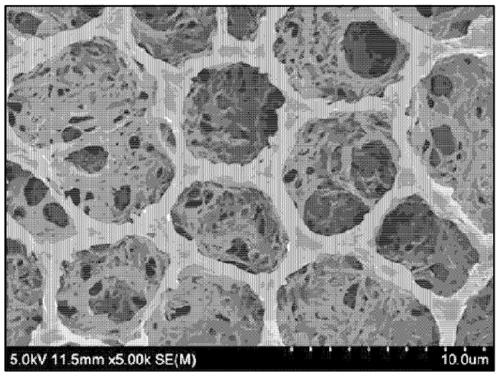

[0109] P(VDF-HFP-CTFE) terpolymer (Vinylidene fluoride-hexafluoropropylene-chlorotrifluoroethylene terpolymer, vinylidene fluoride-hexafluoropropylene-trifluoroethylene terpolymer) (weight average molecular weight: 500,000, containing 90 wt. % of repeating units derived from vinylidene fluoride, 5% by weight of repeating units derived from hexafluoropropylene and 5% by weight of repeating units derived from chlorotrifluoroethylene) were added to acetone and dissolved at 50°C for about 4 hours to prepare the binder polymer solution. 500nm Al as inorganic particles 2 o 3 The powder and 250 nm γ-AlOOH powder were mixed in a weight ratio of 9:1 and added to the binder polymer solution at a weight ratio of binder polymer:total inorganic particles=1:4. After adding cyanoethyl polyvinyl alcohol as a dispersant in an amount of 2% by weight of the total amount of inorganic particles, the inorganic particles were pulverized and dispersed for a total of 12 hours using a ball milling me...

Embodiment 2

[0111] A separator with a porous coating is produced by the same method as in Example 1, except that P(VDF-HFP-CTFE) terpolymer (Vinylidene fluoride-hexafluoropropylene-chlorotrifluoroethylene terpolymer, vinylidene fluoride-hexa Fluoropropylene-chlorotrifluoroethylene terpolymer) (weight average molecular weight: 500,000, containing 80% by weight of repeating units derived from vinylidene fluoride, 1% by weight of repeating units derived from hexafluoropropylene, and 19% by weight repeating units derived from chlorotrifluoroethylene).

Embodiment 3

[0113] A separator with a porous coating is produced by the same method as in Example 1, except that P(VDF-HFP-CTFE) terpolymer (Vinylidene fluoride-hexafluoropropylene-chlorotrifluoroethylene terpolymer, vinylidene fluoride-hexa Fluoropropylene-chlorotrifluoroethylene terpolymer) (weight average molecular weight: 500,000, containing 73% by weight of repeating units derived from vinylidene fluoride, 1% by weight of repeating units derived from hexafluoropropylene, and 26% by weight repeating units derived from chlorotrifluoroethylene).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com