Integrated all-solid-state secondary battery

A secondary battery, all-solid technology, applied in the field of integrated all-solid secondary batteries, to achieve the effect of reducing side reactions, reducing interface resistance, and improving interface resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0075] Embodiments of the present invention will be described in detail below. The specific embodiments are provided only as examples of the present invention, and the present invention is not limited thereto. The scope of the present invention is to be determined only by the following claims.

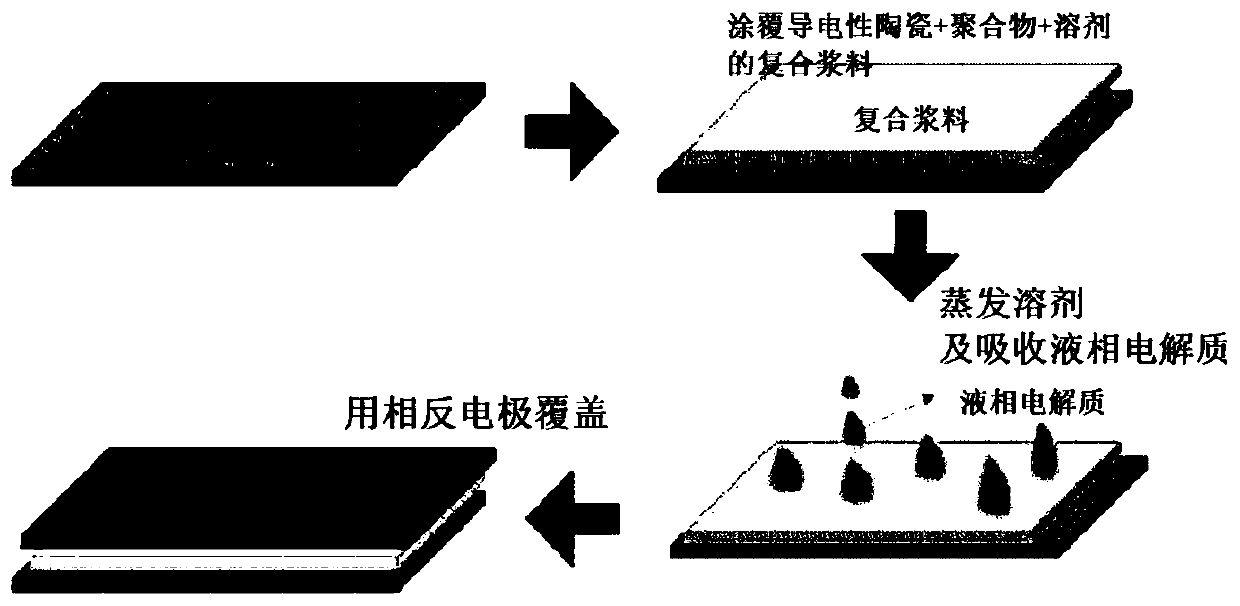

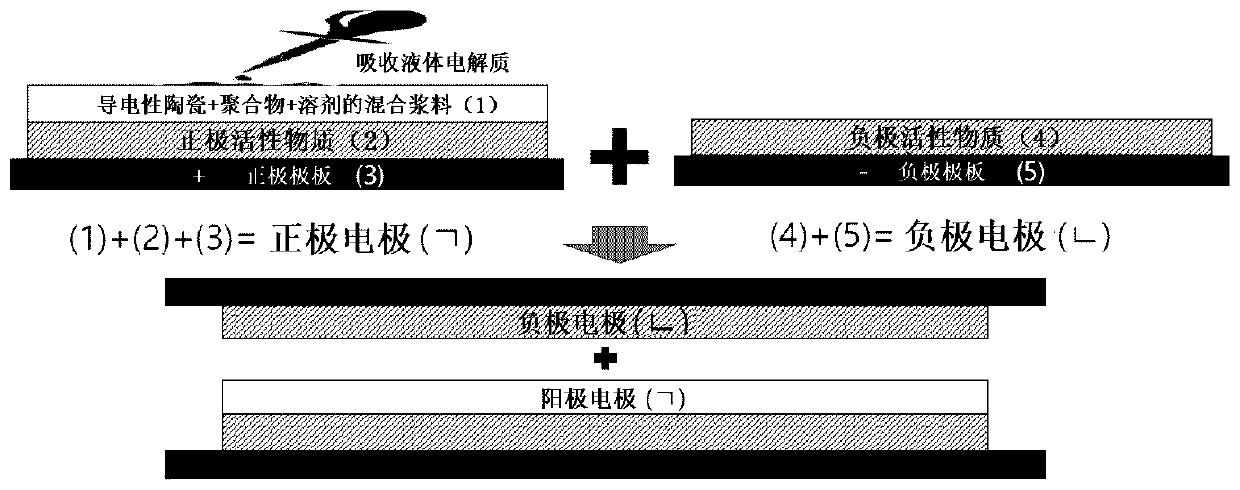

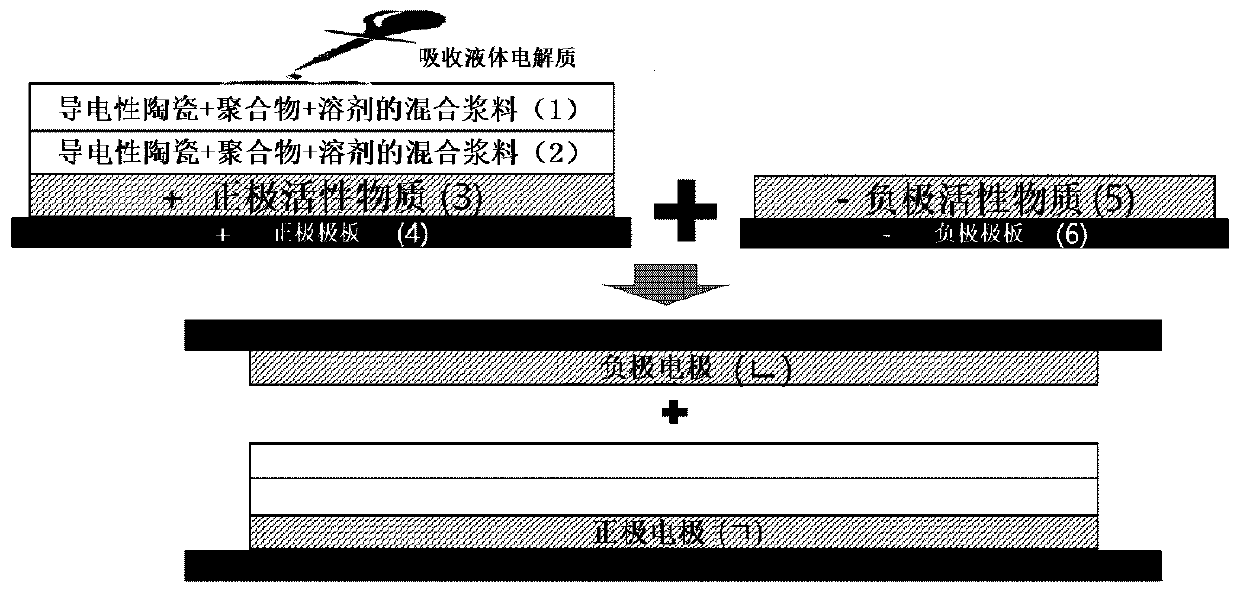

[0076] In the present invention, a mixed slurry including a conductive ceramic material, a polymer, and a solvent is applied to an electrode, and after the solvent is evaporated, the liquid electrolyte is absorbed, and then the counter electrode is covered. Therefore, compared with the existing method, the present invention can manufacture an integrated all-solid secondary battery more simply.

[0077] Methods for absorbing liquid electrolytes include dipping, dripping, and pouring etc., but not limited to this.

[0078] The method of applying the mixed slurry to the electrode includes a printing method, a blade coating method, a spin coating method, and a spray coating method, etc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com