Separation film for lithium secondary battery having adhesive layer

A technology of adhesives and compositions, which is applied in the direction of secondary batteries, lithium batteries, battery pack components, etc., and can solve the problems of insufficient electrode adhesion

Active Publication Date: 2019-09-17

LG ENERGY SOLUTION LTD

View PDF13 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

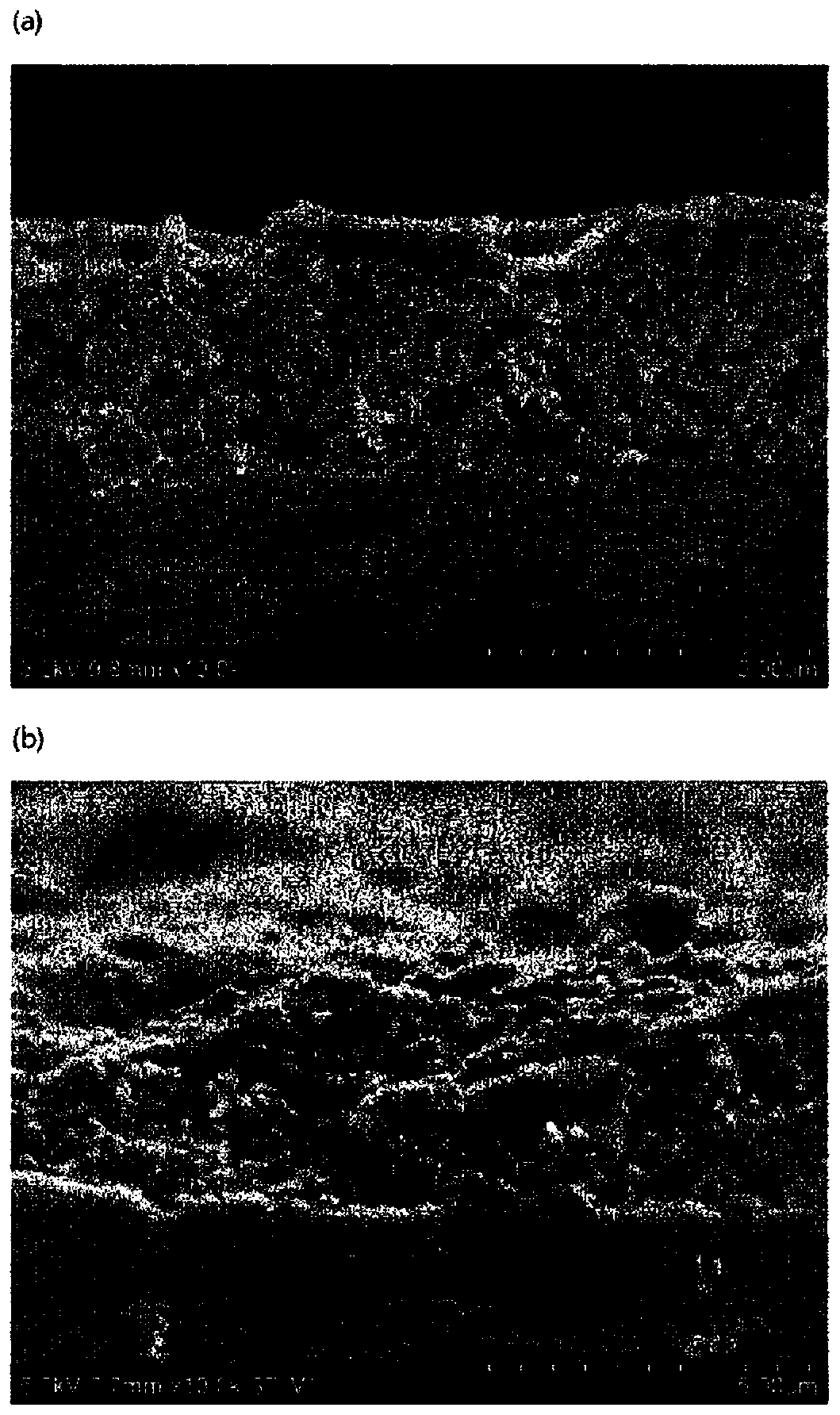

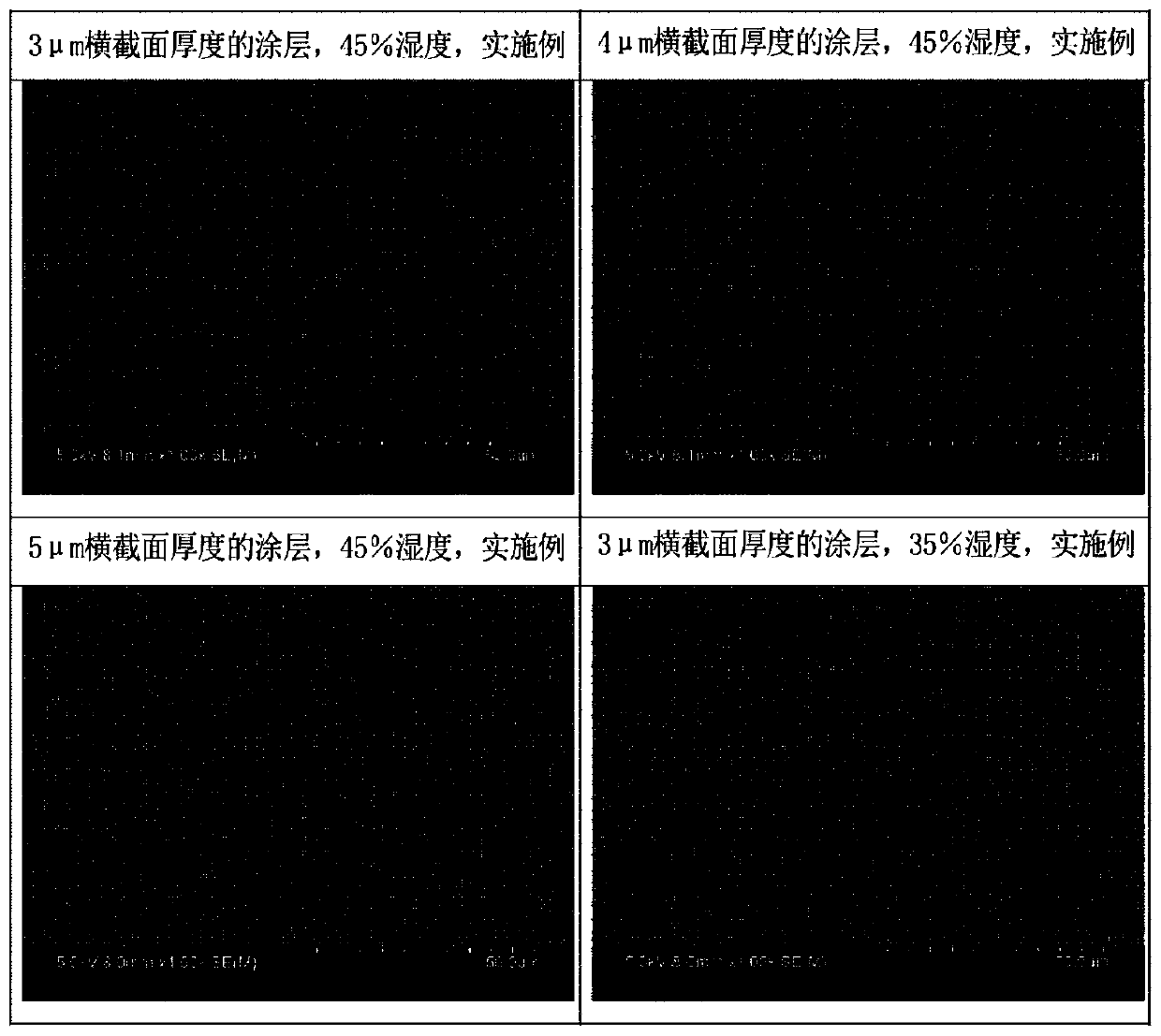

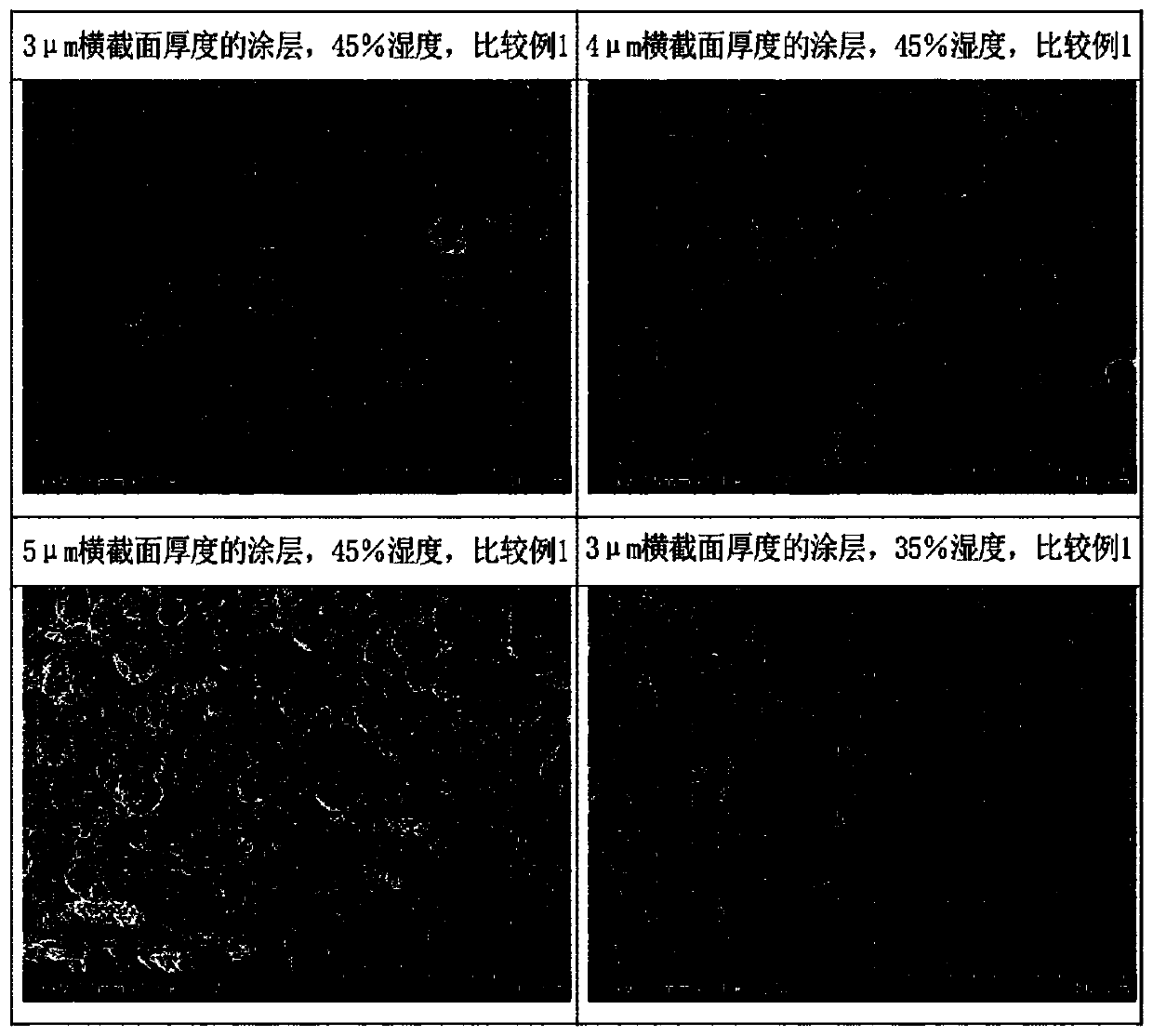

In particular, when the coating thickness of the separator is reduced from 4 μm to 3 μm (based on the cross-section), the coating composition of the present invention can solve the problem of not obtaining sufficient electrodes due to the drying of the binder before sufficient phase separation. problem of stickiness and is able to achieve sufficient phase separation even at the low humidity of the manufacturing method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0083] 1) Preparation of adhesive

[0084] Binder solutions according to Examples of the present invention and Comparative Examples 1 and 2 were prepared as follows.

[0085]

[0086] Adhesive A: PVDF-HFP, molecular weight 400,000, HFP content 8%

[0087] Adhesive B: PVDF-HFP, molecular weight 900,000, HFP content 14%

[0088] The mixing weight ratio of adhesive A and adhesive B is 1:1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

The present invention relates to a coating composition, comprising a solvent, inorganic particles, a dispersant, and a binder, for coating at least one surface of a porous substrate having a plurality of pores. The binder comprises binder B and binder A, wherein the binder B and the binder A both contain a vinylidene fluoride (VDF)-derived unit and a hexafluoropropylene (HFP)-derived unit. The HFP-derived unit accounts for 8% to 50% by weight of the binder B, and in the binder A, the HFP-derived unit is not more than 80% of the proportion thereof in the binder B and is not less than 5% by weight of the binder A. The total number average molecular weight of the binder B is 200,000 to 2,000,000, and the total number average molecular weight of the binder A is 70% or less of that of the binder B. The weight ratio of binder A: binder B in the total coating composition is 0.1 to 10: 1. The present invention has resolved the problem that when a binder is thinned from 4 to 3 , the binder is dried before being sufficiently phase-separated and thus a sufficient electrode adhesive force cannot be obtained, and also in terms of a manufacturing method, the present invention has provided a coating composition in which sufficient phase separation occurs even in a low-humidity condition.

Description

technical field [0001] The present invention relates to a coating composition for a separator of a lithium secondary battery comprising an adhesive layer, and more particularly to a coating composition suitable for coating at least one surface of a separator of a porous substrate having a plurality of pores thereon, for comprising A coating composition for a lithium secondary battery separator of an adhesive layer. Background technique [0002] As the recent trend is to reduce weight and increase functions of portable devices such as smartphones, notebook computers, tablet computers, and portable game consoles, the demand for secondary batteries to be used as a driving power source for these portable devices is increasing. In the past, nickel-cadmium, nickel-hydrogen, and nickel-zinc batteries have been used, but lithium secondary batteries having a high operating voltage and high energy density per unit weight are most commonly used at present. [0003] A problem with lith...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M2/16H01M10/052H01M50/417H01M50/42H01M50/423H01M50/426H01M50/429H01M50/451H01M50/454H01M50/457

CPCH01M10/0525Y02E60/10H01M50/44H01M50/446H01M50/417H01M50/429H01M50/454H01M50/451H01M50/457H01M50/42H01M50/426H01M50/423H01M10/052H01M50/443H01M50/449H01M50/491H01M50/411H01M50/414H01M50/46C09D7/45C09D7/61C09D7/65C09D127/16

Inventor 郑邵美成东昱张大成

Owner LG ENERGY SOLUTION LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com