Lithium secondary battery

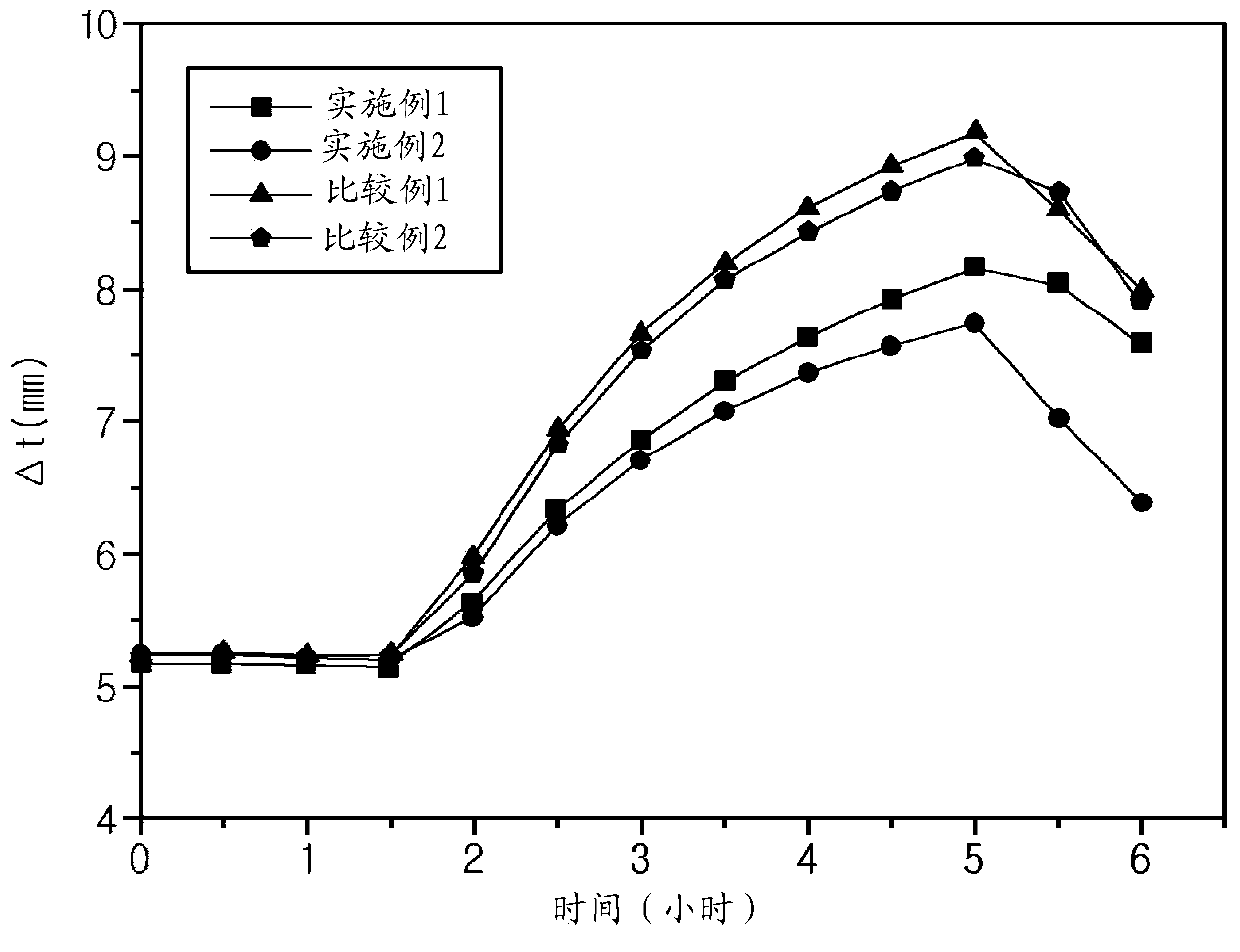

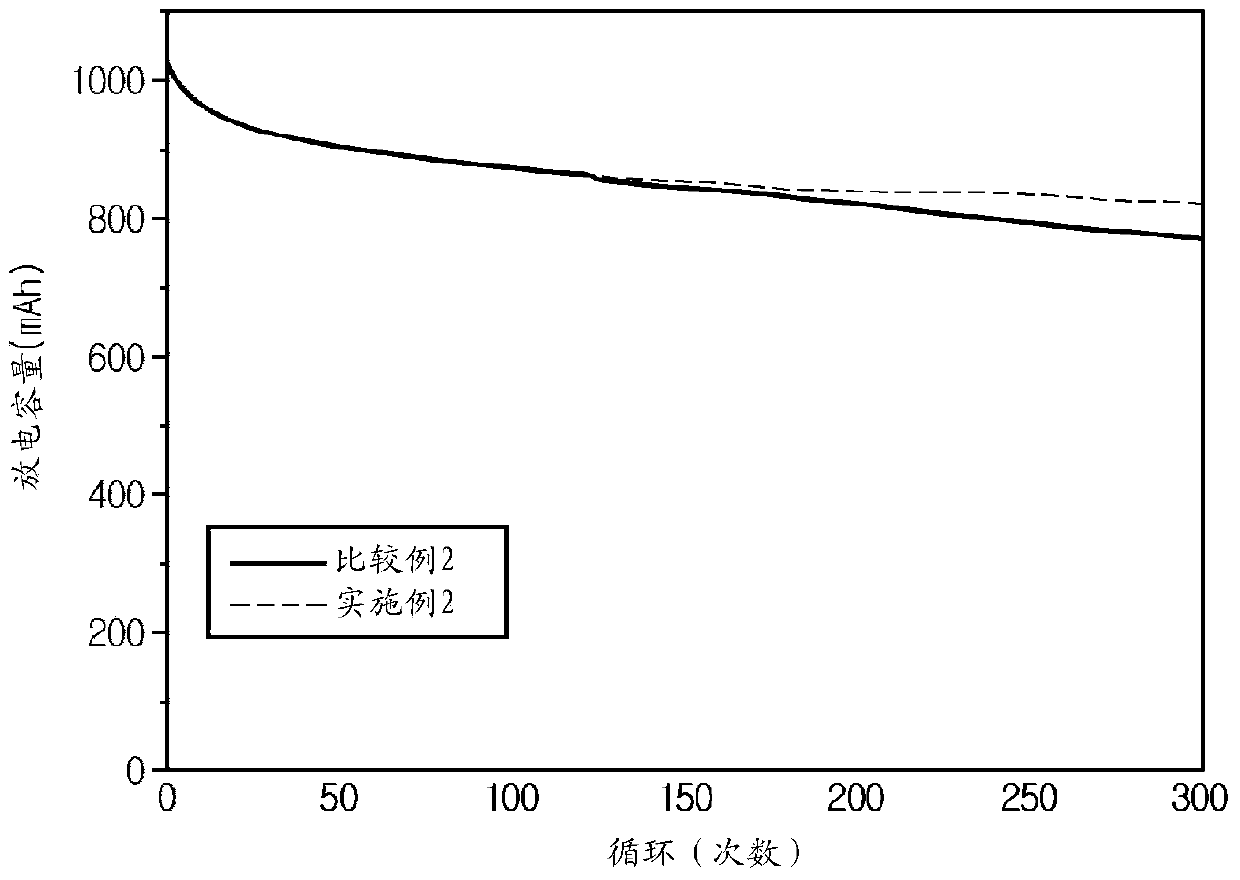

A lithium secondary battery, lithium salt technology, applied in secondary batteries, lithium storage batteries, battery electrodes, etc., can solve problems such as no solution, stable battery structure deformation, thermal instability, etc., to reduce battery swelling, The effect of suppressing the generation of gas and improving the overall performance of the battery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

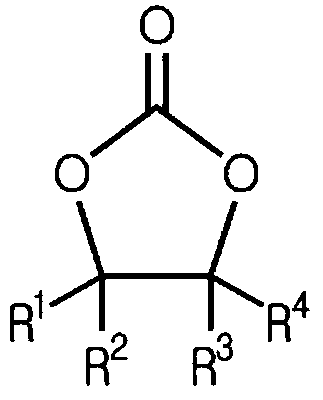

Method used

Image

Examples

Embodiment 1

[0078] 1-1. Preparation of positive electrode

[0079] Will D 50 LiCoO with a single-phase structure of about 15 to 20 μm 2 , and D 50 LiNi of about 5 to 8 μm (agglomeration of fine particles of about 1 to 2 μm) 0.53 mn 0.27 co 0.2 o 2 Mix at a mixing ratio of 7:3 to prepare positive electrode active materials.

[0080] The mixed positive electrode active material is mixed with Super-P as a conductive material and polyvinylidene fluoride as a binder in a weight ratio of 92:4:4, and then N-methylpyrrolidone (NMP) is added to prepare slurry. The prepared positive electrode slurry was coated on an aluminum current collector and dried in a vacuum oven at 120° C. to prepare a positive electrode.

[0081] 1-2. Preparation of electrolyte solution

[0082] Use 1M LiPF with composition EC:PC:DEC=3:2:5 6 solution as an electrolyte, and 3% by weight of vinylene carbonate (VC), 2% by weight of fluoroethylene carbonate (FEC), and 3% by weight of ethylene glycol bispropionitrile (...

Embodiment 2

[0086] A lithium polymer battery was prepared in the same manner as in Example 1 except for using ethylene glycol bisacrylonitrile in a content of 5% by weight.

Embodiment 3

[0088] In addition to using 2% by weight of ethylene carbonate (VEC) to replace 3% by weight of vinylene carbonate (VC), and using a content of 5% by weight of ethylene glycol bisacrylonitrile, the same as in Example 1 Lithium polymer batteries were prepared in the same manner.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com