Variable inductor type mems pressure sensor using magnetostrictive effect

A pressure sensor and magnetostrictive technology, applied in magnetostrictive devices, material selection for magnetostrictive devices, manufacture/assembly of magnetostrictive devices, etc. Problems such as large shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail with reference to the accompanying drawings.

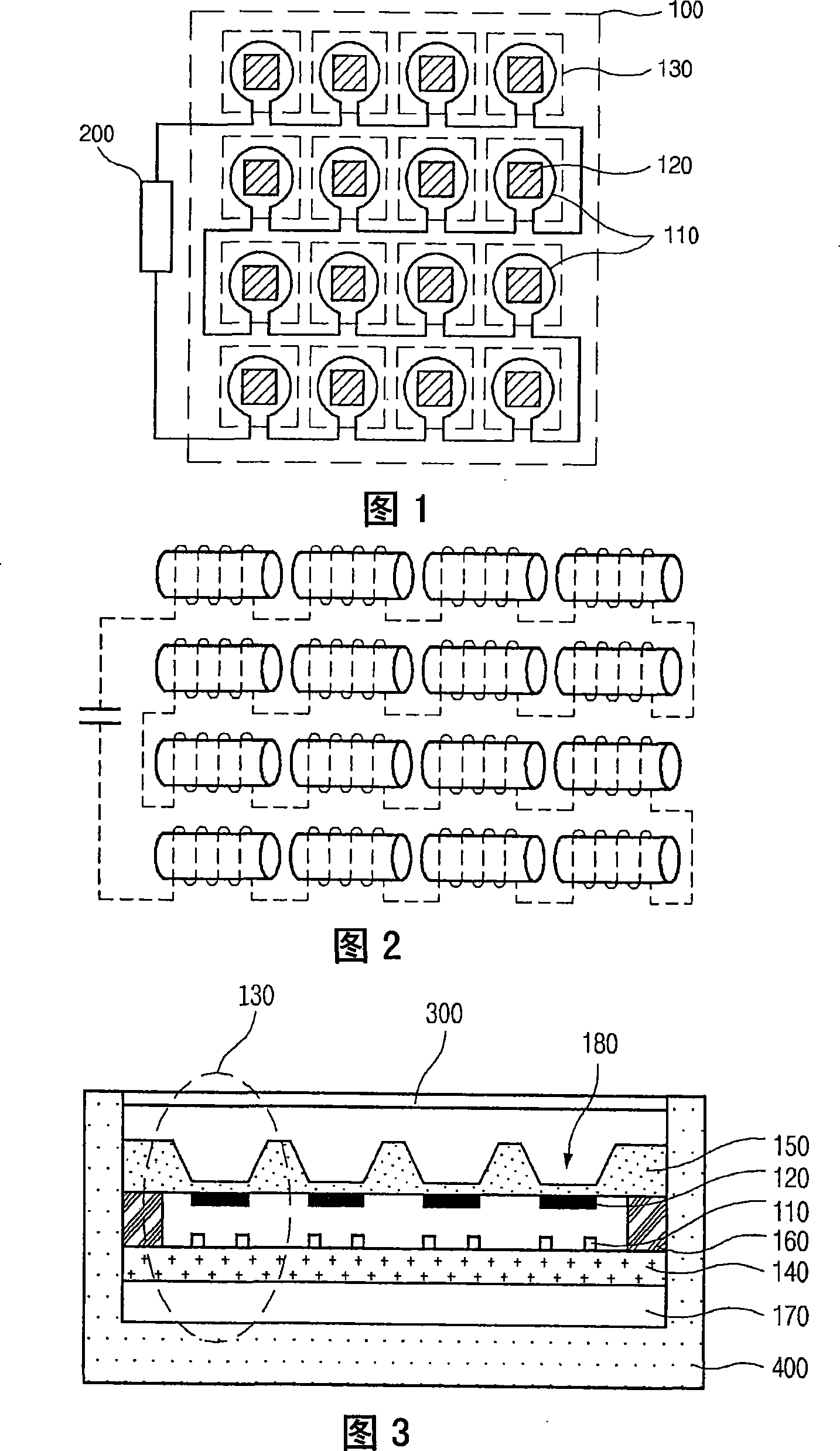

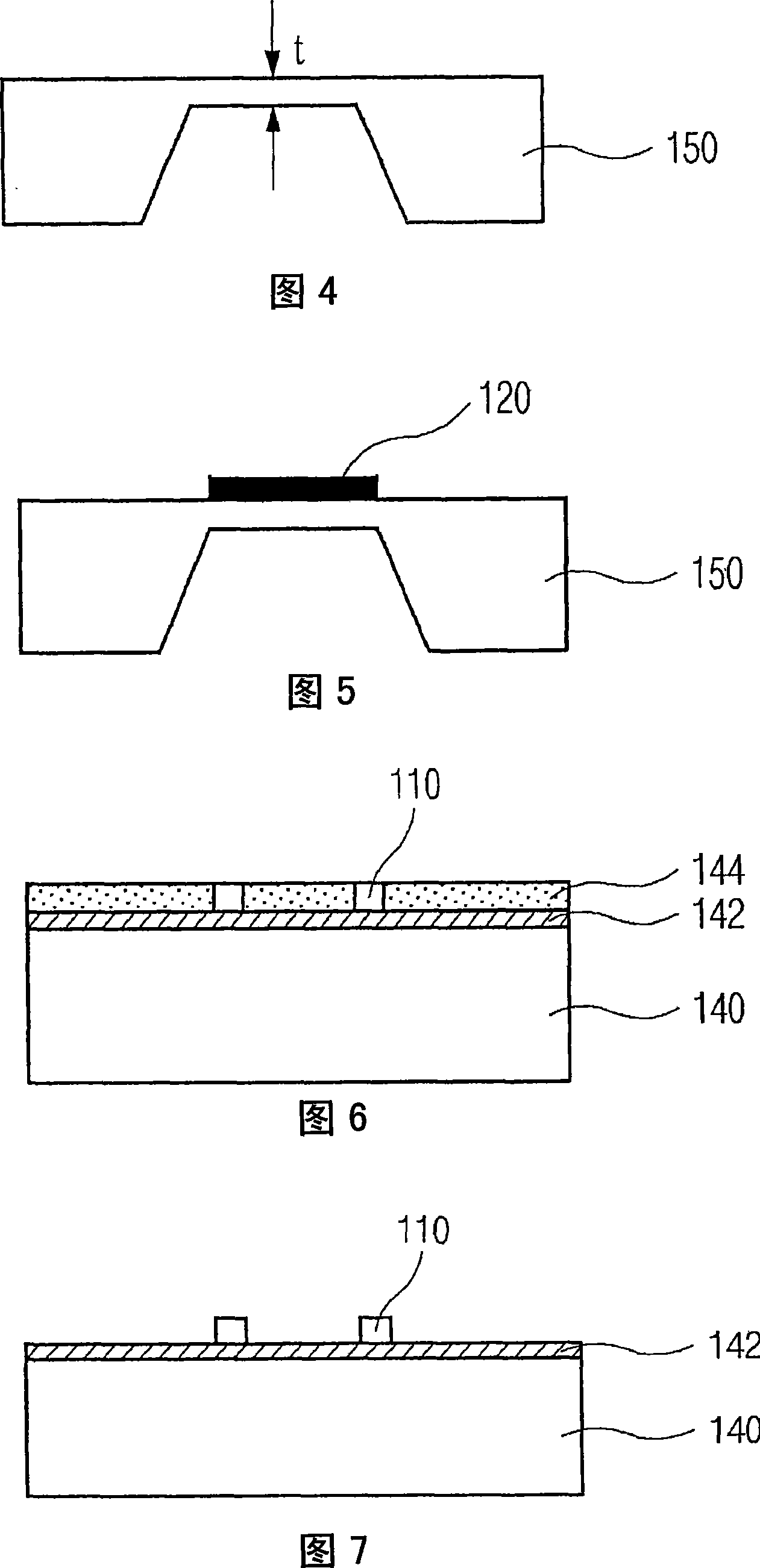

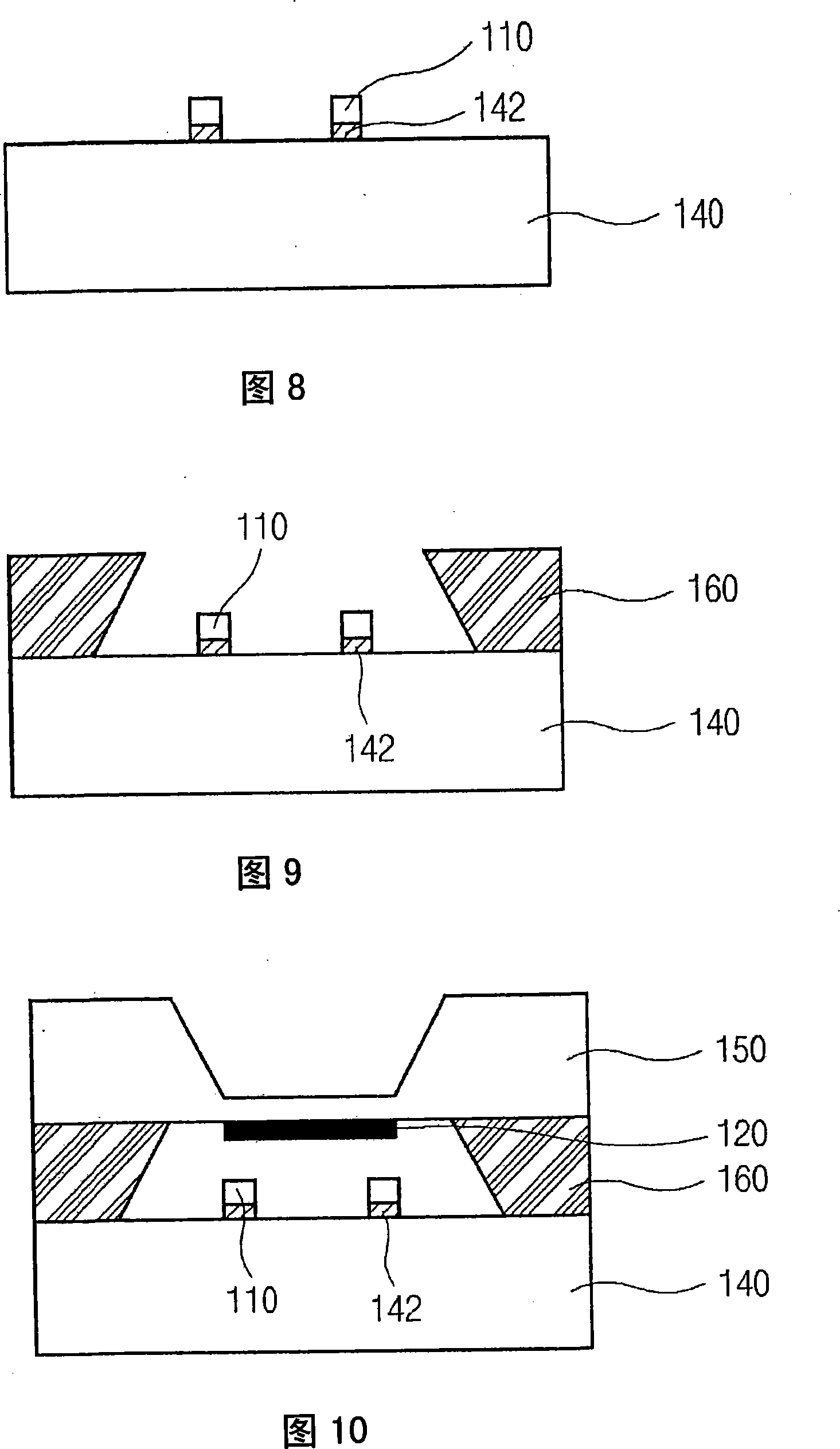

[0020] FIG. 1 is a plan view showing a variable inductance MEMS pressure sensor utilizing a magnetostrictive effect according to an embodiment of the present invention.

[0021] In an embodiment, a variable inductance MEMS pressure sensor utilizing a magnetostrictive effect includes an inductance array unit 100 and a capacitance unit 200, which form an LC resonance circuit.

[0022] The magnetic permeability of the thin film of the magnetostrictive material is changed based on the pressure applied from the outside, and the inductance array unit 100 senses the change of the thin film of the magnetostrictive material, thereby changing the inductance of the sensor. The inductor array unit 100 includes a plurality of unit elements 130 . Each unit element 130 includes a ring coil electrode 110 and a thin film 120 of a magnetostrictive material corresponding to the ring coil elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com