Cantilever magnetic sensor, as well as preparation method and using method thereof

A magnetic sensor, cantilever beam technology, applied in the manufacture/assembly of magnetostrictive devices, magnetostrictive devices, components of magnetostrictive devices, etc., can solve the problems of the detection accuracy and range of magnetic sensors at room temperature. , to achieve the effect of good application prospect and high sensitivity magnetic field detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

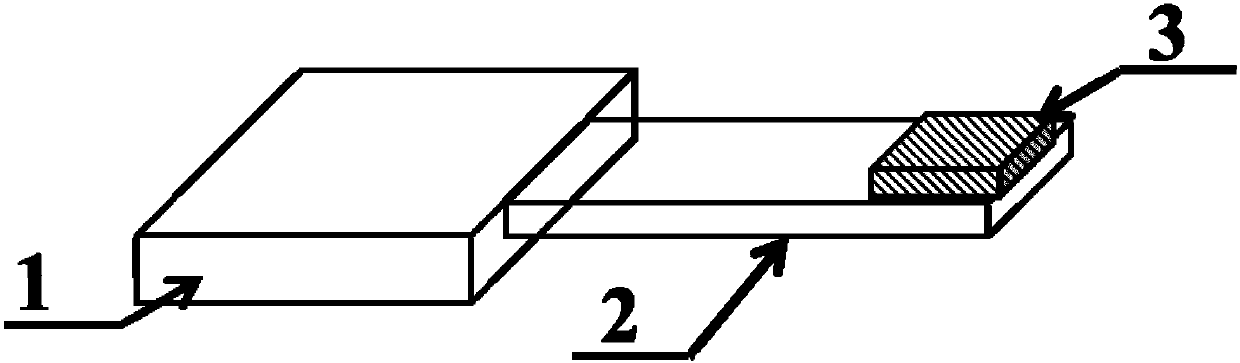

[0030] In this embodiment, the structure of the cantilever beam type magnetic sensor is as follows figure 1 As shown, it includes a base 1 and a cantilever beam 2, one end of the cantilever beam 2 is fixed on the base 1, and the other end is a free end, and a magnet 3 is arranged at the free end of the cantilever beam.

[0031] The base has a cuboid structure and is composed of laminated thin film materials. From bottom to top, there are silicon layer, silicon dioxide layer, aluminum gallium nitride layer and gallium nitride layer. The length of the base is 500 microns, the width is 500 microns, and the thickness is 1000 microns.

[0032] The cantilever has a cuboid structure and is composed of an AlGaN layer and a GaN layer. The cantilever has a length of 250 microns, a width of 40 microns, and a thickness of 4 microns.

[0033] The magnet is a thin film of nickel 100 nanometers thick.

[0034] The preparation method of the above-mentioned cantilever beam type magnetic sens...

Embodiment 2

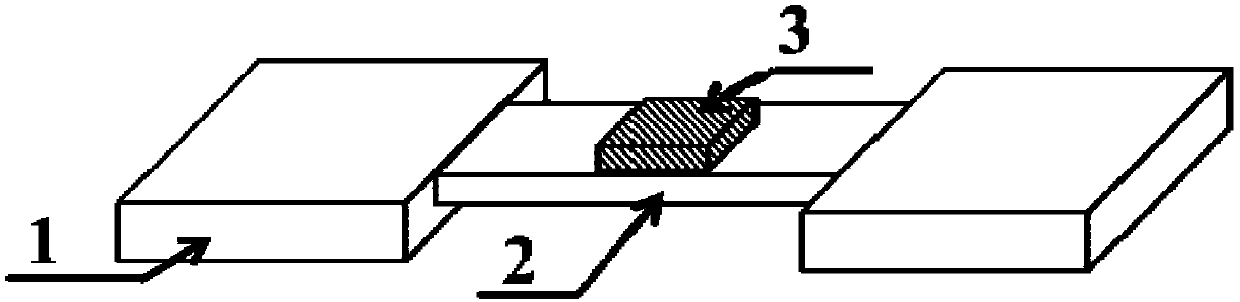

[0044] In this embodiment, the structure of the cantilever beam type magnetic sensor is as follows figure 2 As shown, it includes two bases 1 and a cantilever beam 2, one end of the cantilever beam 2 is fixed on the base 1, the other end is fixed on the other base, and a magnet 3 is arranged on the cantilever beam.

[0045] The base has a cuboid structure and is composed of laminated thin film materials. From bottom to top, there are silicon layer, silicon dioxide layer, aluminum gallium nitride layer and gallium nitride layer. The length of the base is 500 microns, the width is 500 microns, and the thickness is 1000 microns.

[0046] The cantilever has a cuboid structure and is composed of an AlGaN layer and a GaN layer. The cantilever has a length of 250 microns, a width of 40 microns, and a thickness of 4 microns.

[0047] The magnet is a thin film of nickel 100 nanometers thick.

[0048] The preparation method of the above-mentioned cantilever beam type magnetic sensor ...

Embodiment 3

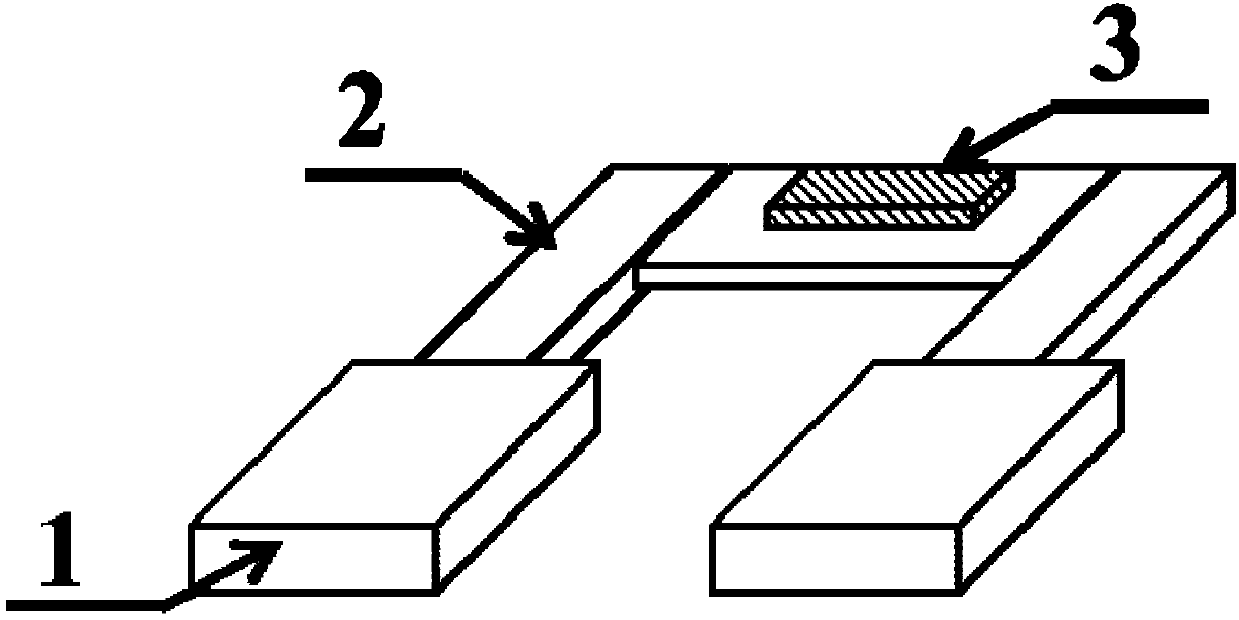

[0059] In this embodiment, the structure of the cantilever beam type magnetic sensor is as follows image 3 As shown, it includes two bases 1 and a cantilever beam 2. The cantilever beam 2 is in a U-shaped structure. One end of the cantilever beam 2 is fixed on the base 1, and the other end is fixed on the other base, and a magnet 3 is arranged on the cantilever beam.

[0060] The base has a cuboid structure and is composed of laminated thin film materials. From bottom to top, there are silicon layer, silicon dioxide layer, aluminum gallium nitride layer and gallium nitride layer. The length of the base is 500 microns, the width is 500 microns, and the thickness is 1000 microns.

[0061] The cantilever has a cuboid structure and is composed of an AlGaN layer and a GaN layer. The cantilever has a length of 250 microns, a width of 40 microns, and a thickness of 4 microns.

[0062] The magnet is a thin film of nickel 100 nanometers thick.

[0063] The preparation method of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com