Methods for making large dimension, flexible piezoelectric ceramic tapes

a flexible piezoelectric ceramic and tape technology, applied in the direction of mechanical vibration separation, device material selection, instruments, etc., can solve the problems of large sheet, difficult to make a thin, limited piezoelectric ceramic material detection/test system application,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

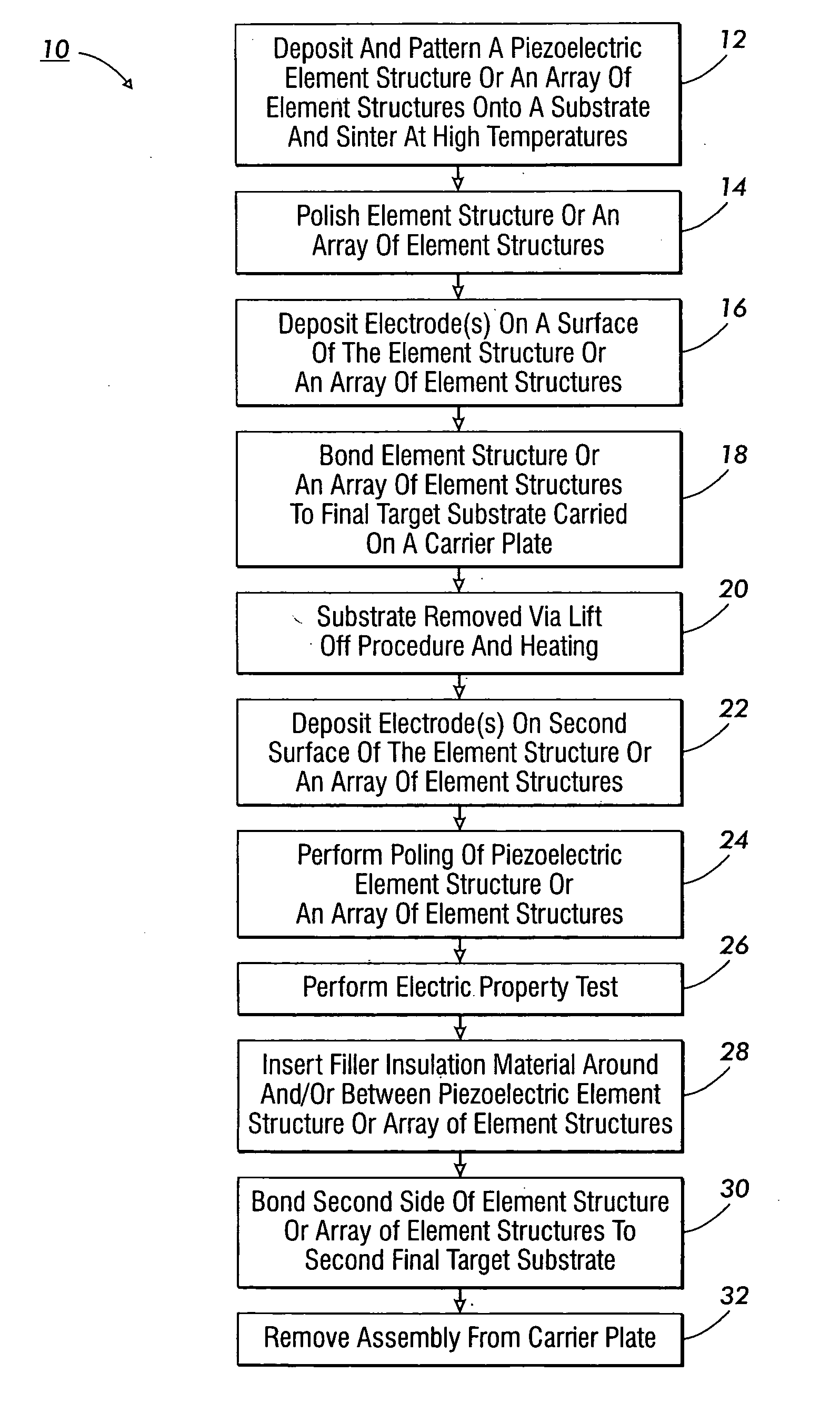

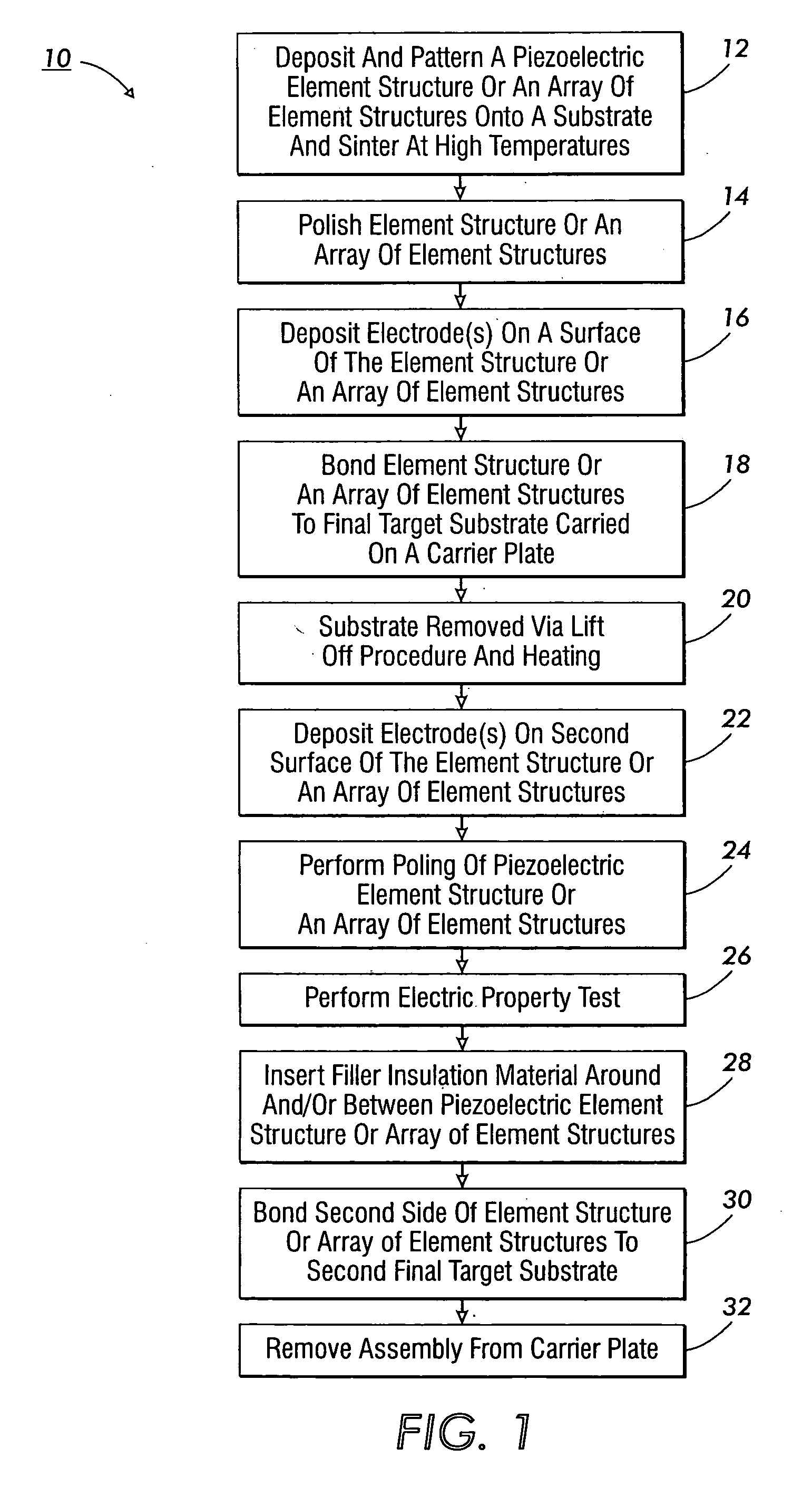

[0042]FIG. 1 illustrates a high level process flow 10 for a manufacturing process according to the concepts of the present application. While the following discussion focuses on producing piezoelectric thick film elements (with thickness between 10 and 100 μm), it is to be appreciated the disclosed processes may be used with other materials and may also be used for production of thin-film elements (with thickness less than 10 μm) and elements with thicknesses greater than 100 μm to millimeter in scale. Also, the following techniques are intended to be applicable to the generation of individual elements and arrays of elements.

[0043] Initially, piezoelectric ceramic thick film elements are fabricated by depositing the piezoelectric material onto an appropriate substrate by use of a direct marking technology 12. In the deposition techniques employed, ceramic type powders are used in a preferred embodiment. The fabrication process includes sintering the material preferably at a temperat...

second embodiment

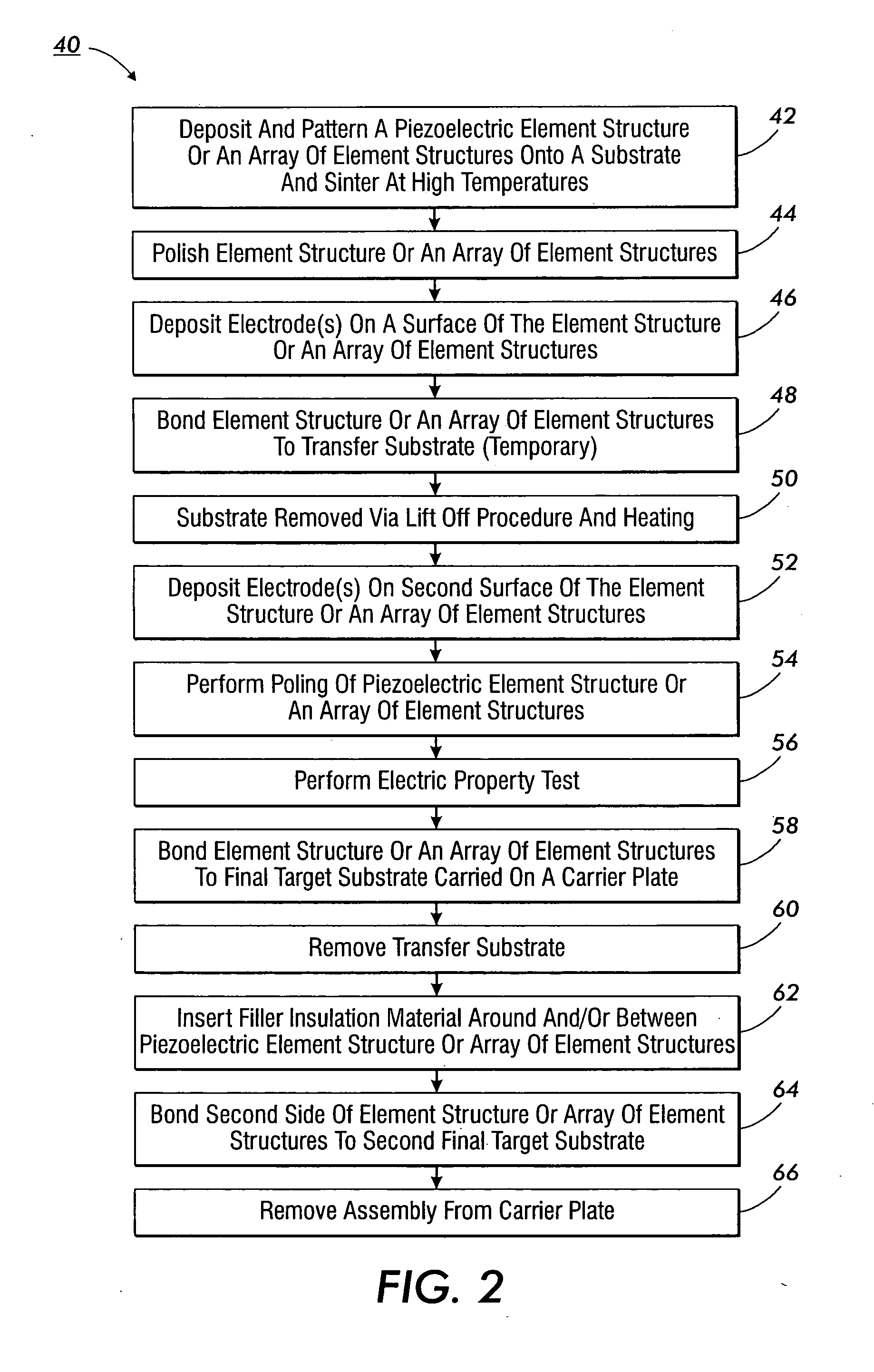

[0045] Turning to FIG. 2, illustrated is a second high-level process flow 40 for the present application. This process differs from FIG. 1 in that the bonding is to a transfer substrate rather than to a final target substrate. Thus, the fabrication step 42, the tape polishing step 44 and the electrode depositing step 46 are performed in the same manner as steps 12, 14 and 16 of FIG. 1. At bonding step 48, the bonding is to a transfer substrate, as this connection is not intended to be permanent. Thereafter, the liftoff step 50, the second electrode deposition step 52, the poling step 54 and electric property test step 56, which correlate to steps 20, 22, 24 and 26 of FIG. 1, are performed.

[0046] The piezoelectric elements are then bonded to a final target substrate 58, in a procedure similar in design to step 18 of FIG. 1. Following bonding step 58, the transfer substrate is removed 60. Thereafter, the steps of inserting an insulative filler 62, bonding to the second final target su...

third embodiment

[0088]FIG. 16 is an A-A sectional view 140. This drawing shows that the density of piezoelectric elements in an area can be changed (i.e., the elements do not need to be evenly distributed in an area), and the piezoelectric elements may be formed in a variety of shapes 142. Thus the function of the piezoelectric tape can be locally adjusted. Filler 144 is distributed around and between the elements.

[0089]FIG. 17 is a polymer tape 150 with a patterned metallization layer 152. Depending on the shape and distribution of the piezoelectric elements, and the design of outside circuits, the metallization layer can be patterned on the polymer tape 150 to connect the piezoelectric elements to external circuits, via circuit lines 154, individually or group by group, where the number of piezoelectric elements between groups can be different. With such circuit connection it is possible to simultaneously have some piezoelectric elements work as sensors, some as actuators, and some as transducers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

| thicknesses | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com