Method for preparing Co-Gd alloy capable of improving soft magnetic performance

A co-gd, alloy technology, applied in the field of magnetic materials, to achieve excellent magnetostrictive properties, rich and colorful solidification structure, and reduce the effect of defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

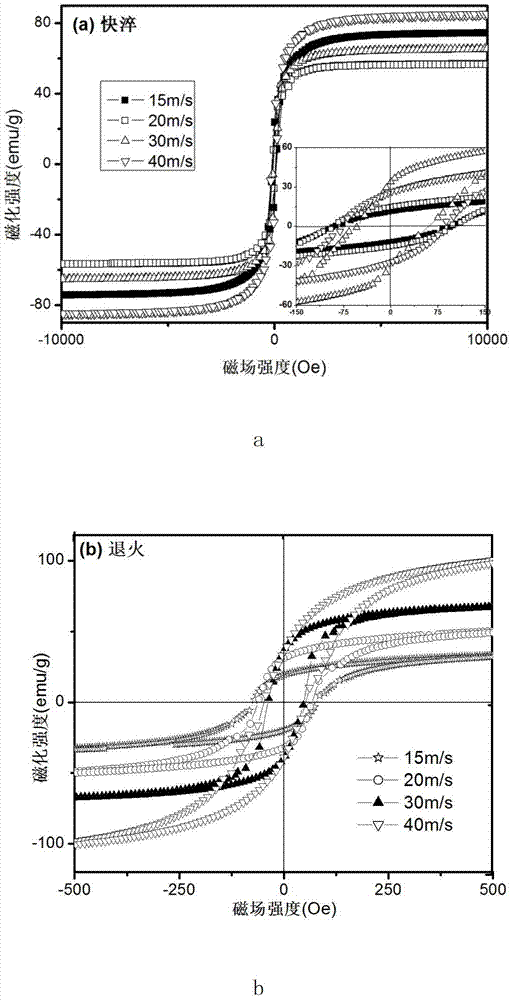

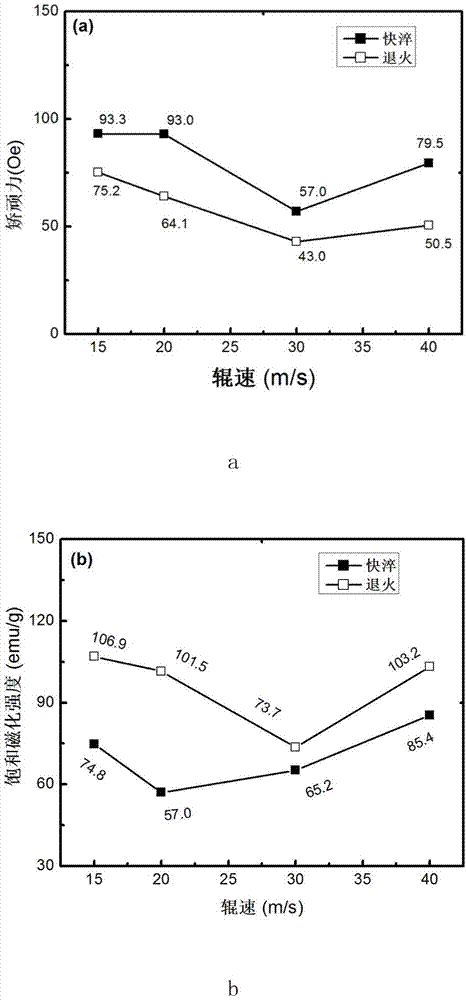

Embodiment 1

[0024] ①Co with a purity of 99.99% and Gd with a purity of 99.9% are melted into a Co-7.5at%Gd alloy under the protection of high-purity Ar gas. The sample mass is 4 grams. The heating time is controlled by an infrared thermometer. Turn off the heat when it reaches level. ②Put the melted alloy into a Φ16mm×150mm quartz test tube with a Φ0.6mm nozzle at the bottom of the vacuum chamber, and evacuate to 2.0×10 -2 Pa back filled with high-purity He gas (99.995%) to 1 atmosphere. Repeat "vacuumizing-inflating" 3~5 times. ③Using high-frequency electromagnetic induction method to heat the fused alloy to melt and overheat above 1500K. After 30 seconds of heat preservation, blow high-pressure Ar gas into the quartz tube, and blow the molten sample to rotate at a linear speed of 15m / s. Alloy thin strips are prepared on a single-roller made of pure copper, and the diameter of the copper single-roller is 120mm. ④Put the prepared alloy strip into the GSL1300X tube furnace, pass through...

Embodiment 2

[0026] ①Co with a purity of 99.99% and Gd with a purity of 99.9% were melted into a Co-7.5at%Gd alloy under the protection of high-purity Ar gas, and the sample mass was 4 grams. Use an infrared thermometer to control the heating time, and stop heating when the heating curve tends to be horizontal. ②Put the melted alloy into a Φ16mm×150mm quartz test tube with a Φ0.6mm nozzle at the bottom of the vacuum chamber, and evacuate to 2.0×10 -2 Pa back filled with high-purity He gas (99.995%) to 1 atmosphere. Repeat "vacuumizing-inflating" 3~5 times. ③Using high-frequency electromagnetic induction method to heat the fused alloy to melt and overheat above 1500K, after 30 seconds of heat preservation, blow high-pressure Ar gas into the quartz tube, and blow the molten sample to rotate at the surface speed of 20m / s Alloy thin strips are prepared on a single-roller made of pure copper, and the diameter of the copper single-roller is 120mm. ④Put the prepared alloy strip into the GSL130...

Embodiment 3

[0028] ①Co with a purity of 99.99% and Gd with a purity of 99.9% were melted into a Co-7.5at%Gd alloy under the protection of high-purity Ar gas, and the sample mass was 4 grams. Use an infrared thermometer to control the heating time, and stop heating when the heating curve tends to be horizontal. ②Put the melted alloy into a Φ16mm×150mm quartz test tube with a Φ0.6mm nozzle at the bottom of the vacuum chamber, and evacuate to 2.0×10 -2 Pa back filled with high-purity He gas (99.995%) to 1 atmosphere. Repeat "vacuumizing-inflating" 3~5 times. ③Using high-frequency electromagnetic induction method to heat the fusion alloy to melt and overheat above 1500K, after 30 seconds of heat preservation, blow high-pressure Ar gas into the quartz tube, and blow the molten sample to rotate at the surface speed of 30m / s Alloy thin strips are prepared on a single-roller made of pure copper, and the diameter of the copper single-roller is 120mm. ④Put the prepared alloy strip into the GSL13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com