Laser-nicked high-magnetic-induction oriented silicon steel and manufacturing method thereof

A technology of high magnetic induction orientation and laser scoring, which is applied in the direction of improving process efficiency to achieve the effect of reducing production cost and excellent magnetostrictive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9

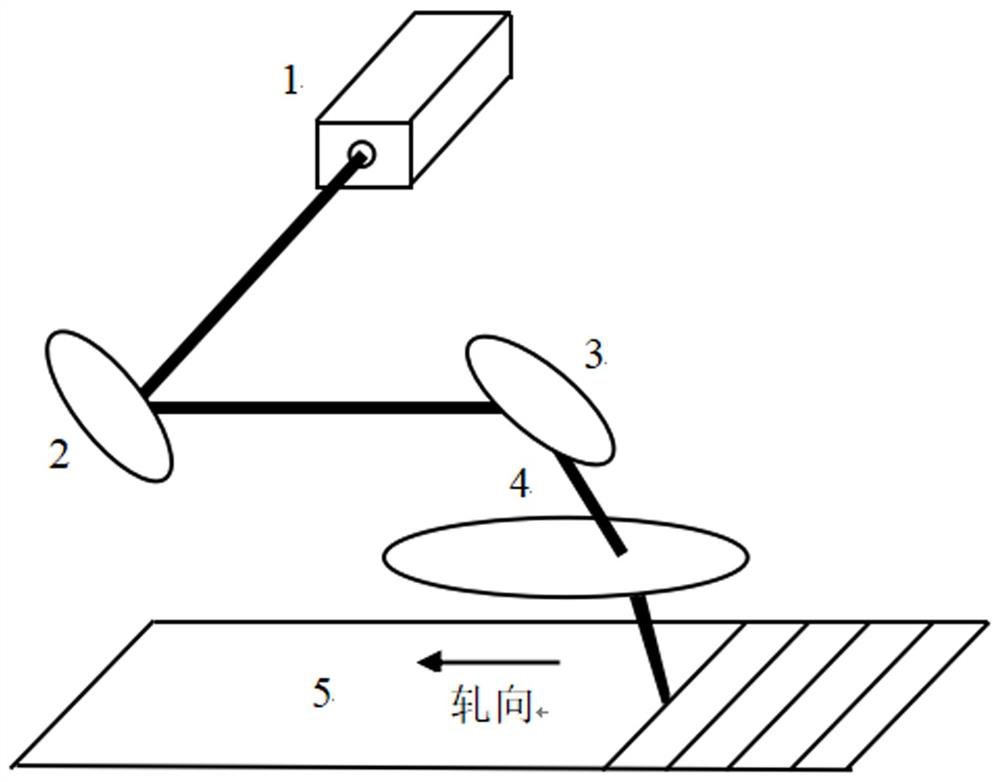

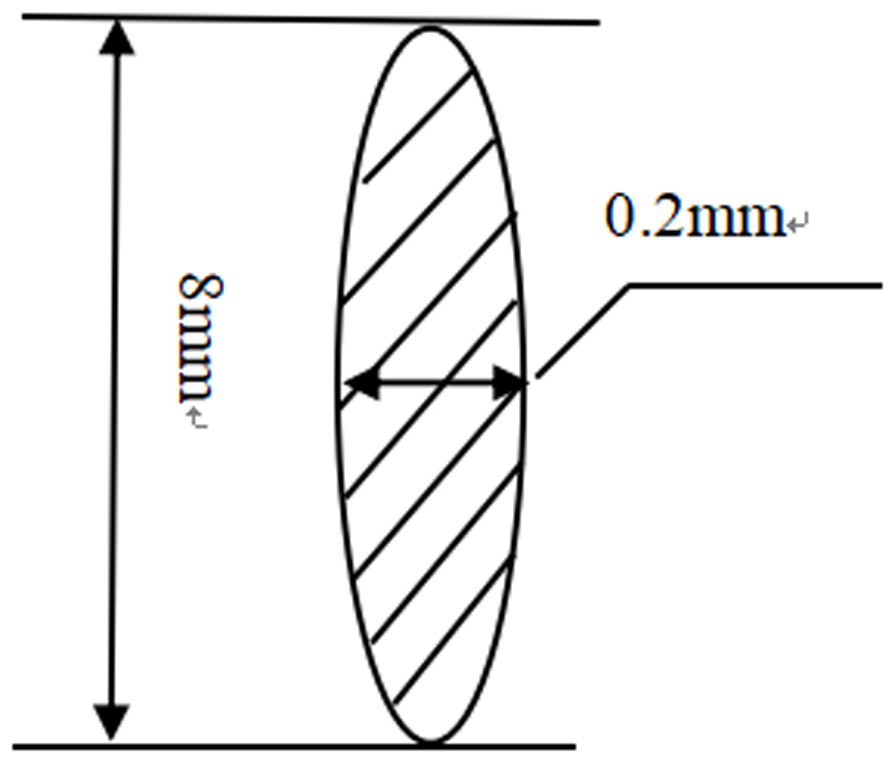

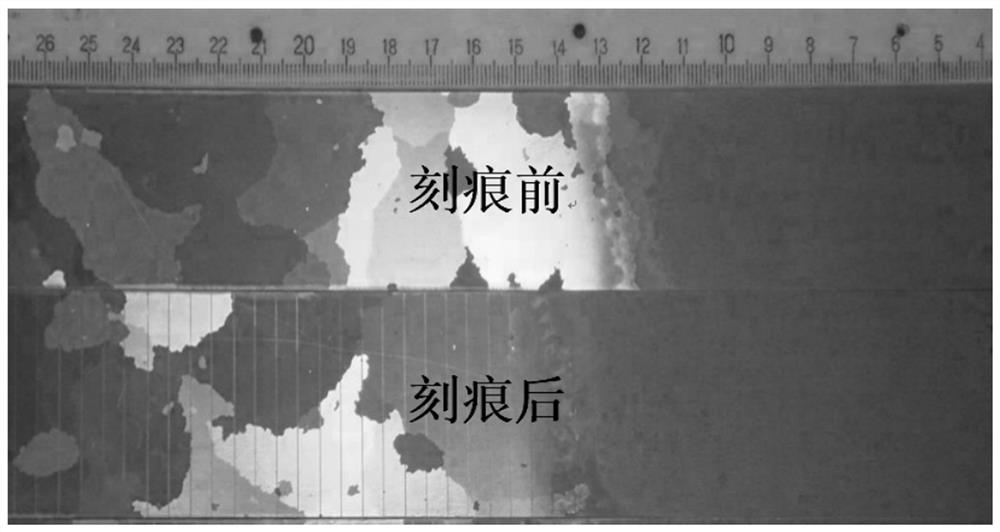

[0029] Examples 1-9 adopt CO 2 The gas continuous wave laser source carries out laser marking on the surface of the oriented silicon steel, and the irradiated laser beam is an elliptical beam with a diameter of 8mm × 0.2mm. See the shape of the spot. figure 2 ; Its long axis is roughly perpendicular to the rolling direction of the steel plate, which can form a superimposed irradiation effect in the scanning direction; continuous overlapping irradiation is formed on the surface of the steel plate at approximately equal intervals to ensure that the energy irradiation of the irradiation surface can be improved under the premise of constant instantaneous energy density, thereby improving the iron loss characteristics of the oriented silicon steel; the laser output power, scanning speed and unit speed are shown in Table 1, and the scanning spacing is 5mm, and finally the "NO-SHOW" type laser notch high magnetic induction orientation with excellent surface quality is obtained Silic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com