Magnetostrictive alloy with excellent mechanical performance and preparation method for magnetostrictive alloy

A magnetostrictive and alloy technology, applied in the field of magnetostrictive alloys and their preparation, can solve the problems of restricting the application of Fe-Ga alloys, unsatisfactory mechanical properties, and high cost, and achieve high yield, excellent mechanical properties, and low cost. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

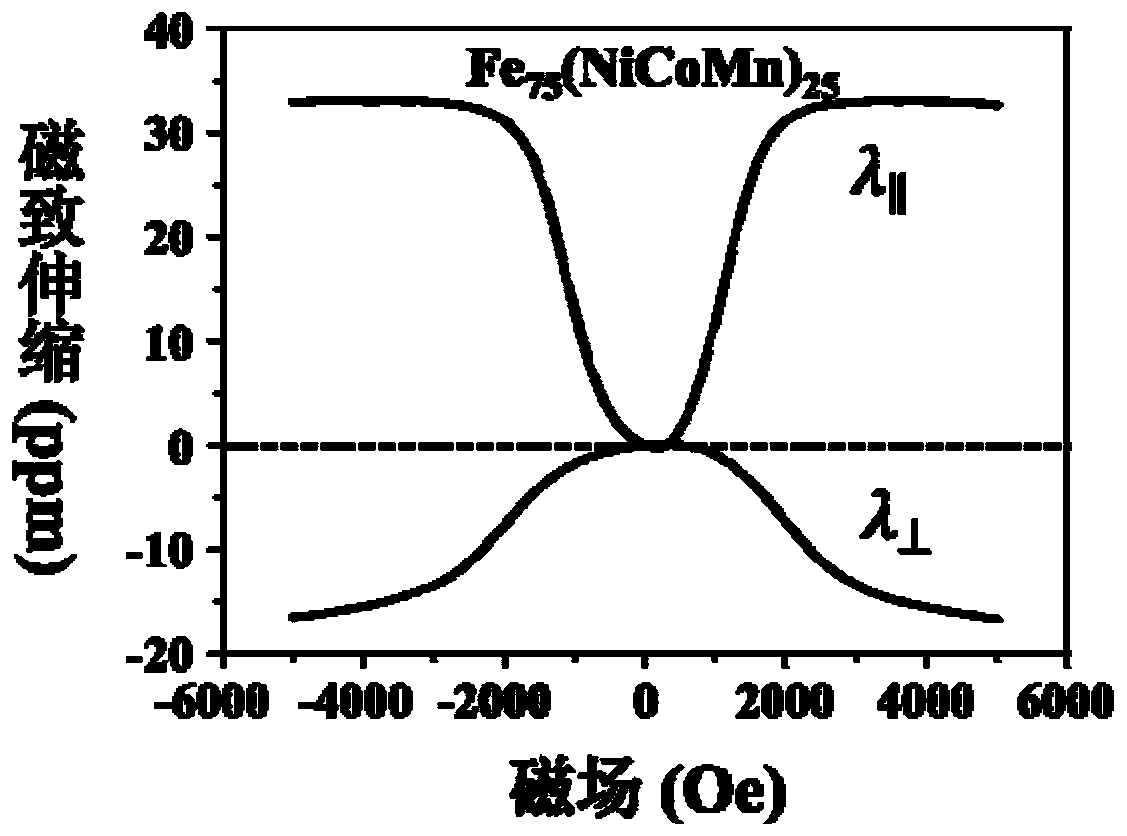

[0037] Magnetostrictive alloy Fe with excellent mechanical properties 75 (NiCoMn) 25 The specific preparation steps are as follows:

[0038] (1) Firstly, polish the oxide skin on the surface of Fe, Co, Ni and Mn, then put it into a beaker containing acetone solution, and place the beaker in an ultrasonic cleaning machine for vibration cleaning for 5 minutes, then take it out and place it on a filter paper for use Hairdryer for drying;

[0039] (2) The surface polished Ni, Co and Mn are dosed according to the atomic ratio of 1:1:1, and the alumina crucible of the high vacuum melting and casting system is melted in the order of bottom Ni, Co and Mn from bottom to top Arrange the raw materials in the center; then, first vacuum the high vacuum melting and casting system to 2×10 -2 Below Pa, fill with argon gas (purity: 99.99vol%) until the internal pressure reaches 0.05MPa, and then use induction heating to melt Ni, Co and Mn into molten metal. After the metal raw materials are...

Embodiment 2~7

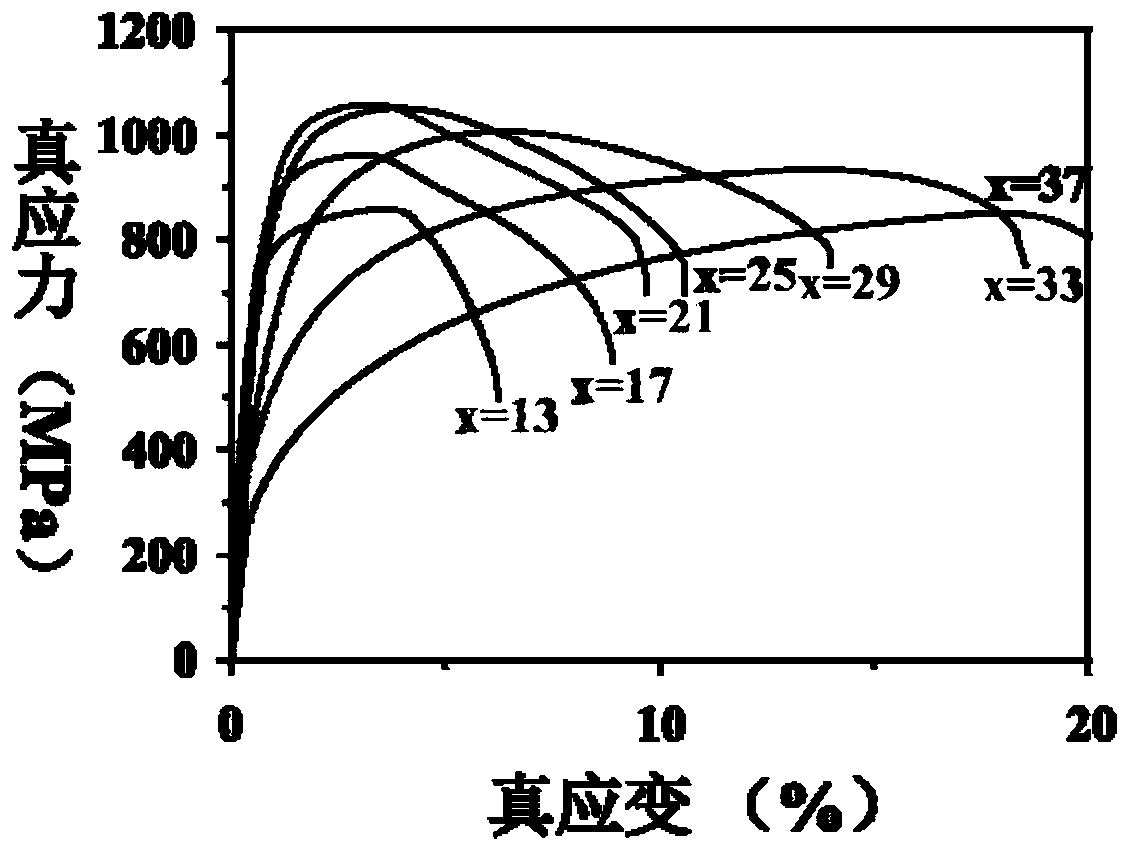

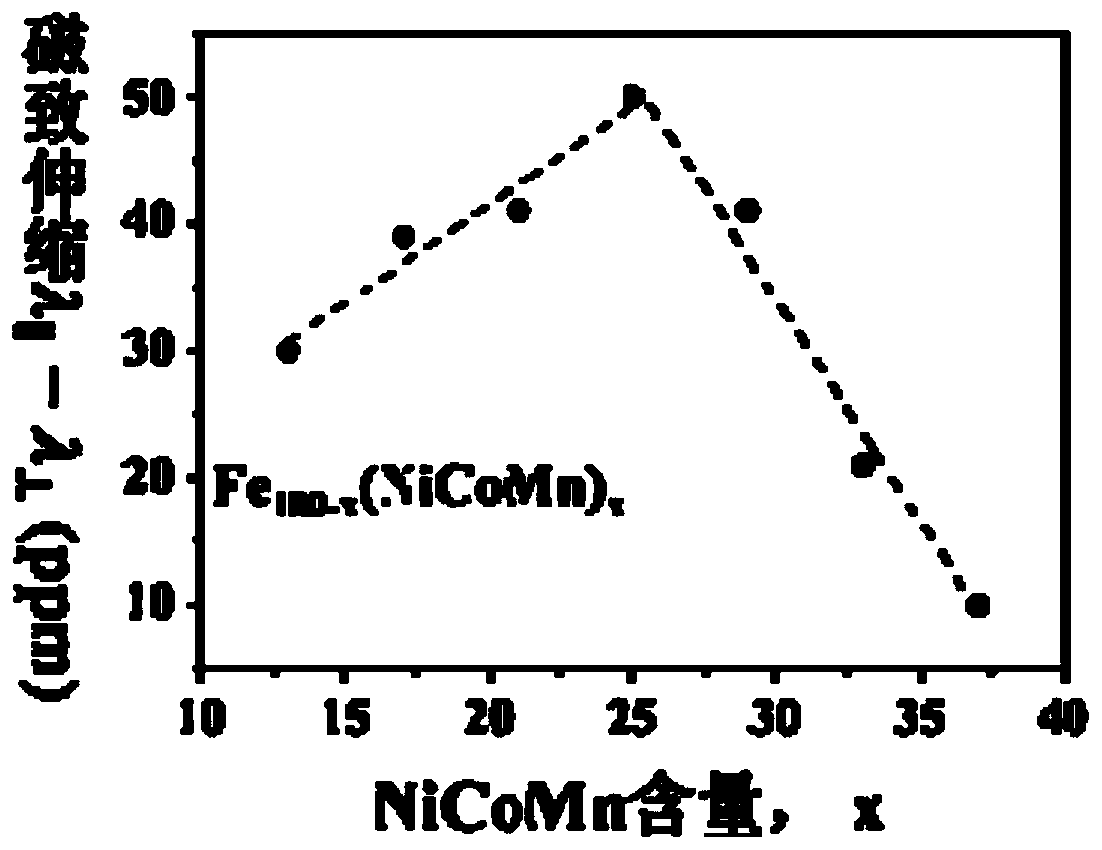

[0042] On the basis of Example 1, the atomic ratio of Fe and NiCoMn alloy ingots in step (3) was revised from 75:25 to 67:33, 71:29, 63:37, 79:21, 83:17 and 87 : 13, other steps and conditions are all the same, then get Fe in turn 67 (NiCoMn) 33 , Fe 71 (NiCoMn) 29 , Fe 63 (NiCoMn) 37 , Fe 79 (NiCoMn) 21 , Fe 83 (NiCoMn) 17 and Fe 87 (NiCoMn) 13 .

[0043] When x=13, 17, 21 and 25, the corresponding Fe 100-x (NiCoMn) x It is a single-phase BCC structure or mainly BCC structure, and the morphology of the BCC phase is as follows Figure 4 As shown, it is composed of lath-like structure with small misorientation and lath clusters with large misorientation. This structure makes the alloy have extremely high strength and also ensures high elongation, such as figure 1 shown. When x=29, 33 and 37, the corresponding Fe 100-x (NiCoMn) x BCC+FCC two-phase coexistence and FCC phase dominates, such as Figure 5 As shown, the two phases of this alloy have a clear boundary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com