Method for improving magnetostrictive property of FeGa alloy

A technology of magnetostriction and performance, applied in the field of magnetic materials, can solve the problems such as magnetostrictive materials of FeGa polycrystalline materials that have not been reported yet, and achieve the effects of excellent magnetostrictive performance, increased service time, and improved magnetostrictive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A cast Fe 82 Ga 18 The preparation method of alloy ingot, described method specific steps are as follows:

[0034] (1) Ingredients

[0035] Using pure iron with a purity greater than 99.99% and pure gallium with a purity greater than 99.99% as raw materials, first polish the surface oxide skin, then put it into a beaker containing acetone solution, and put the beaker into an ultrasonic cleaning machine for vibration cleaning for 5 minutes , then place it on filter paper and dry it with a hair dryer, use an electronic balance to take 4 parts of alloy ingot raw materials according to the ratio of the amount of pure iron and pure gallium to 82:18, each part of 30g;

[0036] (2) Melting

[0037] Using a high-vacuum electric arc melting furnace, the 4 parts of alloy ingot raw materials are arranged in a copper crucible according to pure gallium on the bottom and pure iron on the top, and are smelted to obtain an alloy button ingot;

[0038] The smelting treatment specifi...

Embodiment 2

[0043] An enhanced Fe 82 Ga 18 A method for alloy magnetostrictive properties, said method comprising the steps of:

[0044] (1) the as-cast Fe prepared in embodiment 1 82 Ga 18 Put the alloy ingot into the quartz tube, and evacuate until the vacuum degree is less than 2.5×10 -3 Pa, filled with argon to form a protective atmosphere; first heat the box-type resistance heat treatment furnace to 800 ° C, keep it warm for 10 minutes, then put the quartz tube into the box-type resistance heat treatment furnace, take out the quartz tube after 24 hours of heat preservation, and immediately It is immersed in a sodium chloride solution and quenched to room temperature, and the quartz tube is removed to obtain Fe82-ori;

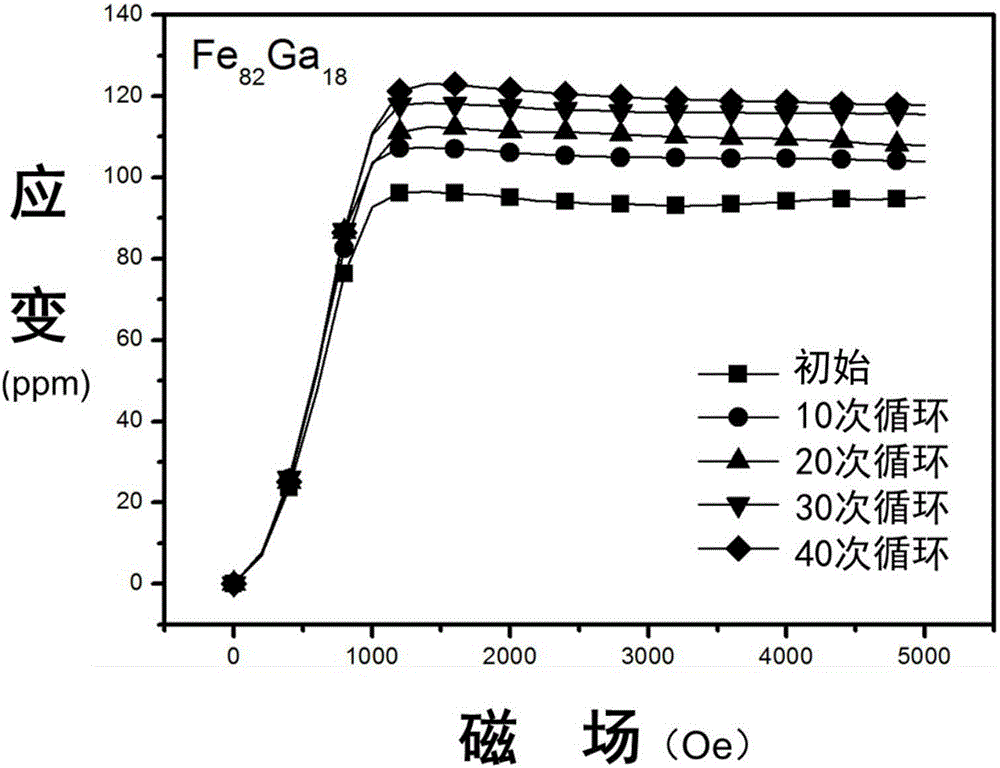

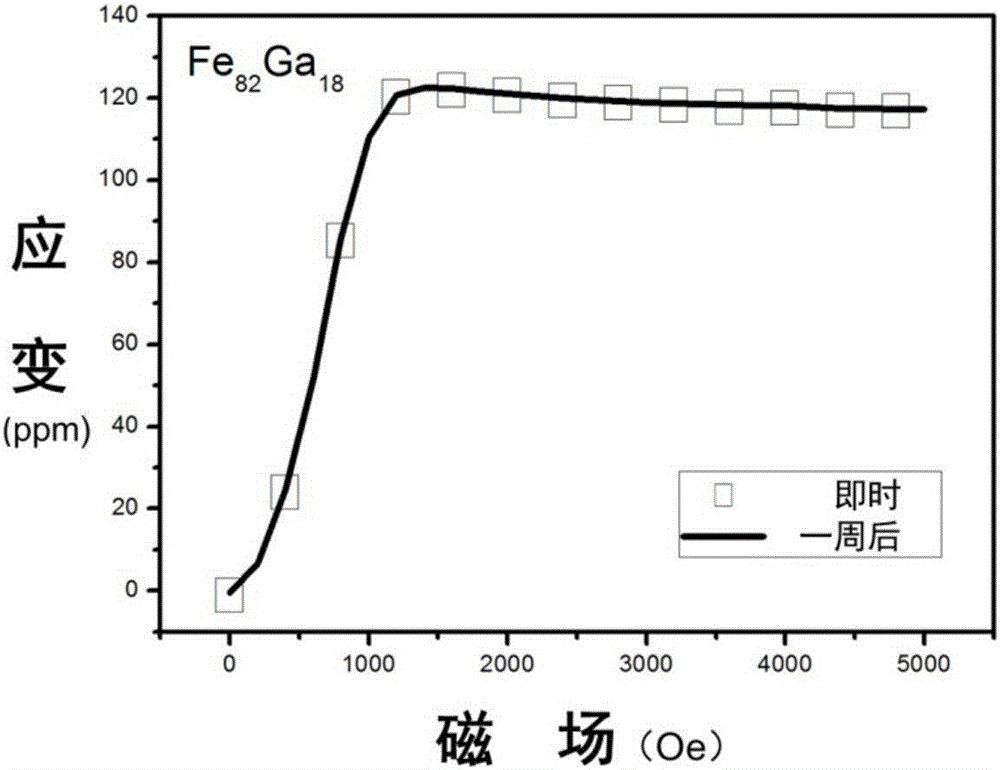

[0045] (2) Submerge Fe82-ori in liquid nitrogen, cryogenically treat for 1 minute, take out the Fe82-ori and immediately utilize a hair dryer to raise its temperature to room temperature; 40 times, obtain a series of FeGa polycrystalline magnetostrictive alloy mat...

Embodiment 3

[0050] A method to improve as-cast Fe 85 Ga 15 The preparation method of alloy ingot, described method specific steps are as follows:

[0051] (1) Ingredients

[0052] Using pure iron with a purity greater than 99.99% and pure gallium with a purity greater than 99.99% as raw materials, first polish the surface oxide skin, then put it into a beaker containing acetone solution, and put the beaker into an ultrasonic cleaning machine for vibration cleaning for 5 minutes , then place it on the filter paper and dry it with a hair dryer, use an electronic balance to take 4 parts of alloy ingot raw materials according to the ratio of the amount of pure iron and pure gallium as 85:15, each part of 30g;

[0053] (2) Melting

[0054] Using a high-vacuum electric arc melting furnace, the 4 parts of alloy ingot raw materials are arranged in a copper crucible according to pure gallium on the bottom and pure iron on the top, and are smelted to obtain an alloy button ingot;

[0055] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com