Giant magnetostrictive vibration source

A technology of giant magnetostrictive and magnetostrictive materials, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve power plant or substation outage, construction period Long, large engineering volume and other issues, to achieve the effect of improved energy conversion efficiency and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

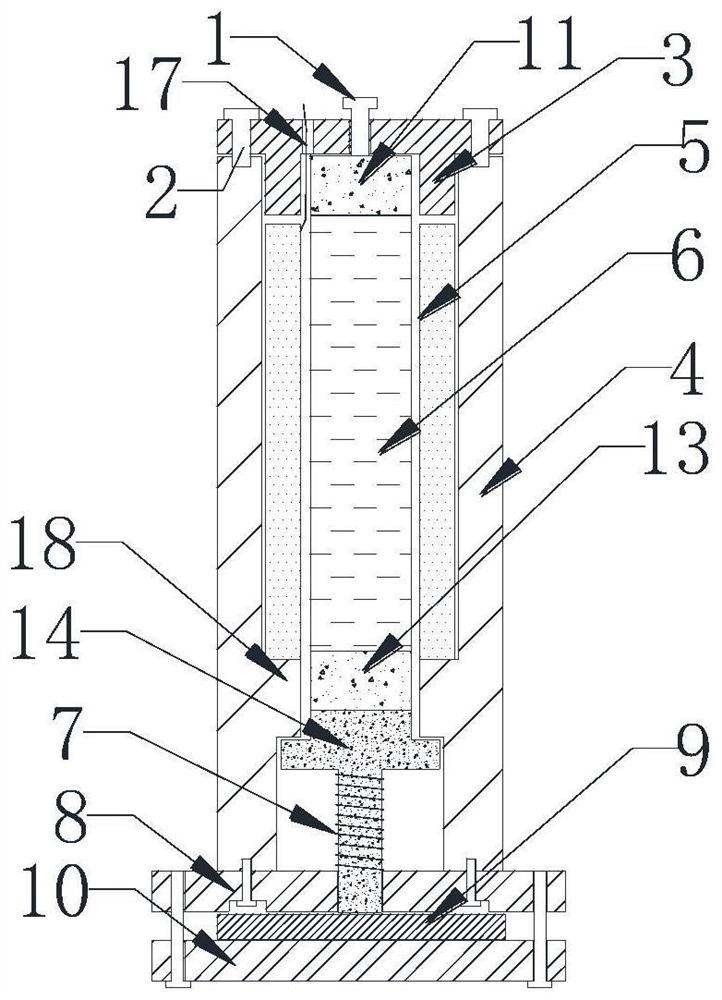

[0040] The specific implementation manner and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

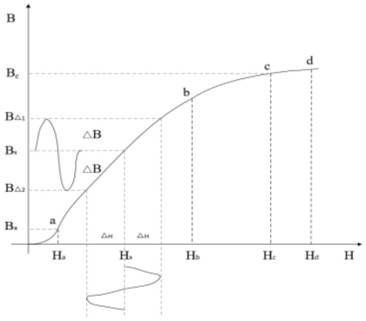

[0041] to combine Figure 1-3 It can be seen that a giant magnetostrictive vibration source includes an excitation coil 5, a magnetostrictive material rod 6 is arranged in the axial direction in the excitation coil 5, and elastic Vibration output member 14, the end of the magnetostrictive material rod 6 away from the telescopic end is provided with a limit end cap 3, when the magnetostrictive material rod 6 is deformed along the direction of the telescopic end under the action of the excitation coil 5, the The detection end of the elastic vibration output member 14 moves along its deformation direction.

[0042] In this embodiment, the magnetostrictive material rod 6 is made of FeGallium alloy. The magnetostrictive material rod 6 adopts Fe83Ga17 alloy.

[0043] Among them, the magnetostrictive mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com