High-performance rare-earth-iron-based giant magnetostrictive material and preparation method thereof

A giant magnetostrictive, high-performance technology, applied in the field of magnetic functional materials, can solve the problems of serious volatilization of rare earth elements and many internal defects in the material, and achieve the effects of excellent magnetostrictive performance, improved magnetostrictive performance, and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

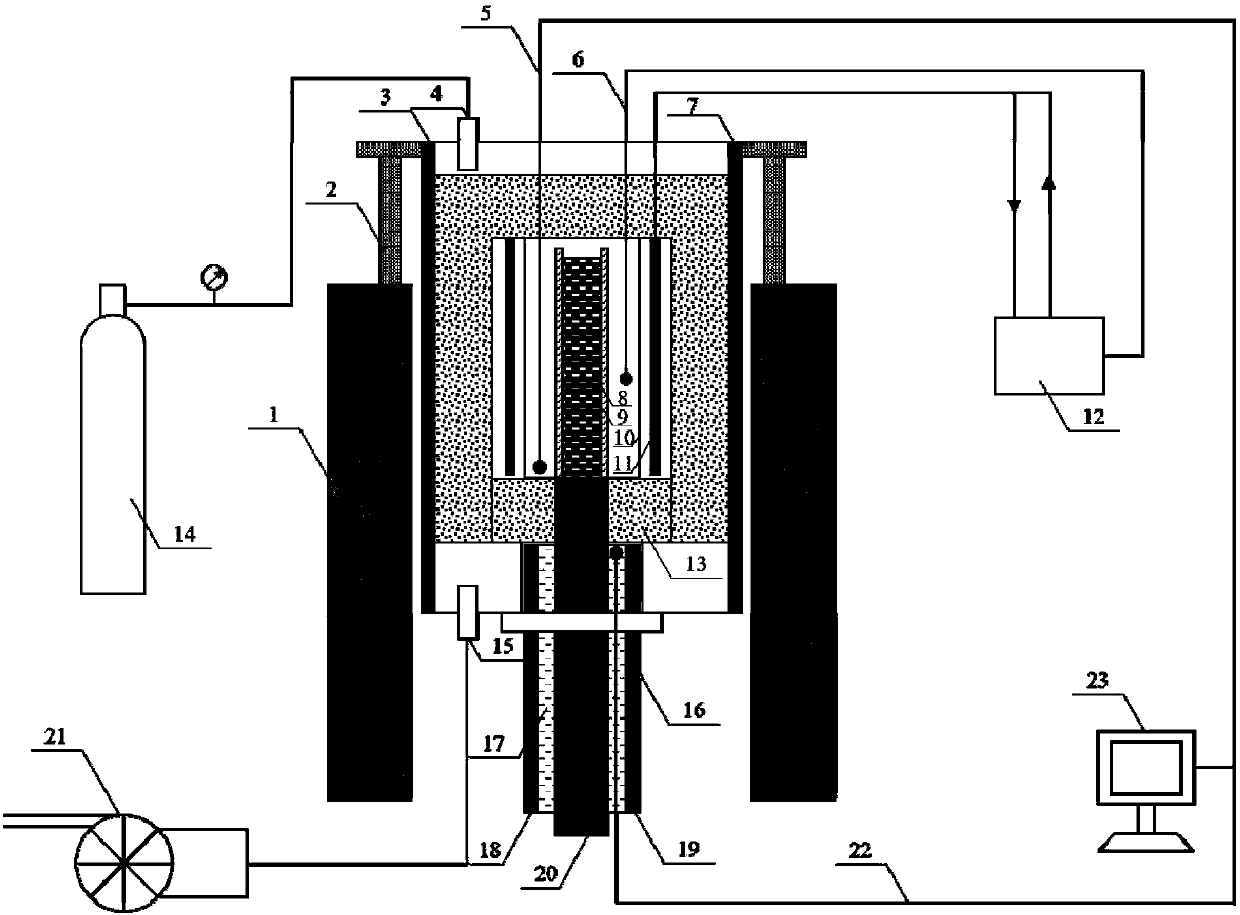

[0035] The device structure of a method for preparing high-performance rare earth-iron-based giant magnetostrictive materials is as follows figure 1 As shown, it includes a strong magnet 1, a heating furnace, and a crucible 9. The heating body 11 of the heating furnace is fixed in the cavity inside the strong magnet through a support frame. The heating furnace also includes a water inlet 3 and a water outlet 7 of the water cooling jacket, heat insulation Layer 10, heat insulation layer 13, and the sample is placed in the crucible 9;

[0036] The temperature-measuring thermocouples 5 and 22 are respectively connected to the bottom of the heating body and the top of the crystallizer, and the other ends of the temperature-measuring thermocouples 5 and 22 are connected to the temperature acquisition system 23;

[0037] The temperature control thermocouple 6 is inserted into the heating furnace to be attached to the insulation layer 10, and placed in the center of the heating body,...

Embodiment 2

[0047] A device for preparing a method for high-performance rare earth-iron-based giant magnetostrictive material is the same as in Example 1;

[0048] Using the device in Example 1, the preparation method is carried out in the following steps:

[0049] Prepare Tb-Dy-Fe master alloy by smelting, the atomic ratio is Tb:Dy:Fe=0.3:0.7:2;

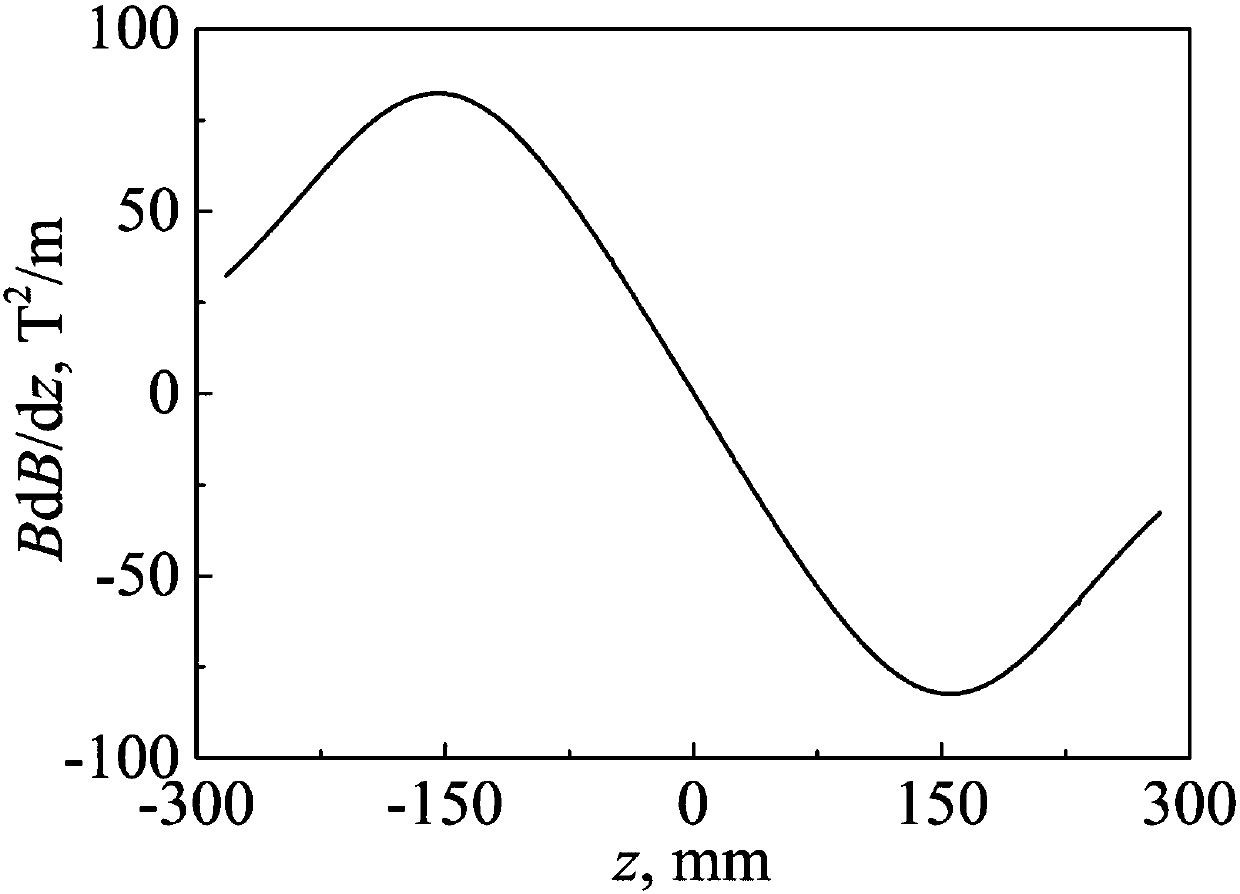

[0050] Put the Tb-Dy-Fe master alloy in the alumina crucible, and evacuate the heating furnace to a vacuum degree of ≤10 -3 Pa, argon gas is introduced to a pressure of 0.02MPa; 60T is applied to the Tb-Dy-Fe master alloy 2 / m gradient strong magnetic field, under the condition of argon protection and gradient strong magnetic field, heat the Tb-Dy-Fe master alloy to the liquid state (1350 ° C), and keep it for 12 minutes;

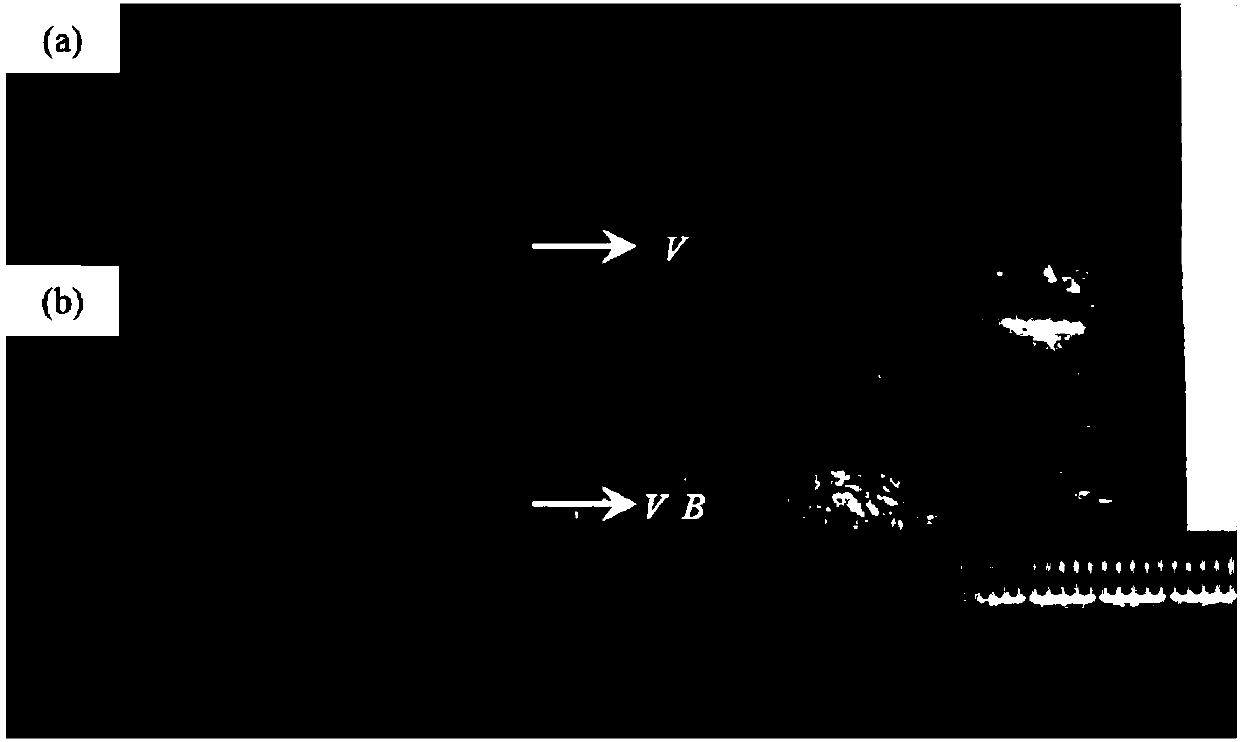

[0051] After the heat preservation is over, the liquid Tb-Dy-Fe master alloy is pulled into the GaInSn cooling liquid at a stretching rate of 25 μm / s to achieve directional solidification, and obtain a Tb-Dy-Fe magnetostri...

Embodiment 3

[0054] A device for preparing a method for high-performance rare earth-iron-based giant magnetostrictive material is the same as in Example 1;

[0055] Using the device in Example 1, the preparation method is carried out in the following steps:

[0056] Prepare Tb-Dy-Fe master alloy by smelting, the atomic ratio is Tb:Dy:Fe=0.35:0.65:1.94;

[0057] Put the Tb-Dy-Fe master alloy in the boron nitride crucible, and evacuate the heating furnace to a vacuum degree of ≤10 -3 Pa, argon gas is introduced to a pressure of 0.03MPa; 40T is applied to the Tb-Dy-Fe master alloy 2 / m gradient strong magnetic field, under the condition of argon protection and gradient strong magnetic field, heat the Tb-Dy-Fe master alloy to the liquid state (1350 ° C), and keep it for 8 minutes;

[0058] After the heat preservation is over, the liquid Tb-Dy-Fe master alloy is drawn into the GaIn cooling liquid at a stretching rate of 15 μm / s to achieve directional solidification and obtain a Tb-Dy-Fe magne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com