High-performance quick-quenching Fe-Ga based magnetostriction thin strip material and preparation technology thereof

A magnetostriction and preparation process technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of small temperature coefficient, large eddy current loss, small magnetic hysteresis, etc., to achieve good flatness and linearity, high magnetic The effect of stretchability and high tape forming rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of high-performance rapid quenching Fe 80.82 Ga 18.76 Tb 0.42 Magnetostrictive Ribbon

[0031] Weigh the raw materials required for the design composition with an electronic balance, and add 3wt% of Ga burnout and 5wt% of Tb burnout, wherein Fe with a purity of 99.95% and Ga and Tb with a purity of 99.99% are used, and the prepared The raw materials are put into the vacuum non-consumable electric arc furnace, and the vacuum degree is 2×10 -3 Pa, 400Pa argon gas is introduced as a protective atmosphere and then heated to melt the raw materials into an alloy. After melting, it is refined for 3 minutes to ensure the uniformity of the alloy composition.

[0032] The alloy ingot was processed into a 8mm×8mm×15mm cuboid sample with a molybdenum wire cutting machine, and then the surface of the alloy sample was cleaned and kept in a dry state.

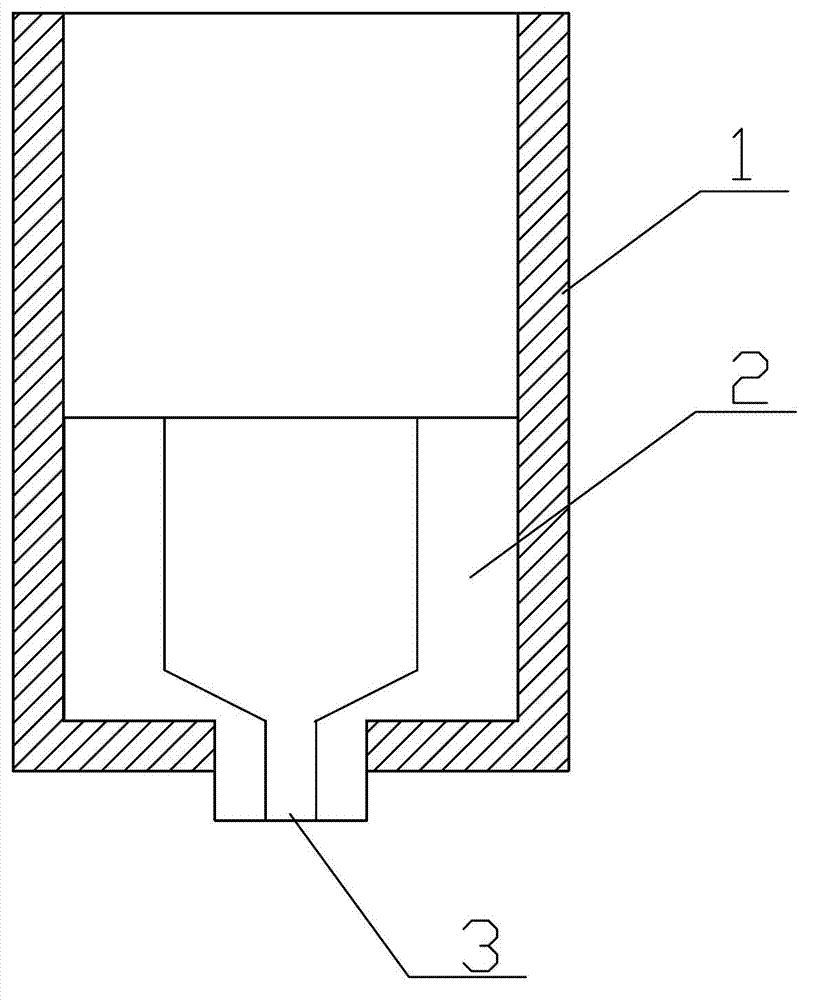

[0033] Put the cuboid sample into a quick quenching container consisting of a copper crucible 2 with an...

Embodiment 2

[0036] Embodiment 2: Preparation of high-performance rapid quenching Fe 79.65 Ga 17.38 Ce 2.97 Magnetostrictive Ribbon

[0037] Weigh the raw materials required for the design composition with an electronic balance, and add 3 wt % of Ga burnout and 4 wt % of Ce burnout, wherein Fe with a purity of 99.95% and Ga and Ce with a purity of 99.99% are used. The raw materials are put into the vacuum non-consumable electric arc furnace, and the vacuum degree is 2×10 -3 Pa, 400Pa argon gas is introduced as a protective atmosphere and then heated to melt the raw materials into an alloy. After melting, it is refined for 3 minutes to ensure the uniformity of the alloy composition.

[0038] The alloy ingot was processed into a 8mm×8mm×15mm cuboid sample with a molybdenum wire cutting machine, and then the surface of the alloy sample was cleaned and kept in a dry state.

[0039] Put the cuboid sample into a quick quenching container consisting of a copper crucible 2 with an opening 3 at...

Embodiment 3

[0042] Embodiment 3: Preparation of high-performance rapid quenching Fe 78.26 Ga 9.82 al 11.78 Y 0.14 Magnetostrictive Ribbon

[0043] Use an electronic balance to weigh the raw materials required for the design composition, and add 3 wt % of Ga burnout, 2 wt % of Al burnout and 4 wt % of Y burnout, and use Fe with a purity of 99.95% and 99.99% % Ga, Al, Y, put the prepared raw materials into the vacuum non-consumable electric arc furnace, and the vacuum degree is 2×10 -3 Pa, 400Pa argon gas is introduced as a protective atmosphere and then heated to melt the raw materials into an alloy. After melting, it is refined for 3 minutes to ensure the uniformity of the alloy composition.

[0044] The alloy ingot was processed into a 8mm×8mm×15mm cuboid sample with a molybdenum wire cutting machine, and then the surface of the alloy sample was cleaned and kept in a dry state.

[0045] Put the cuboid sample into a quick quenching container consisting of a copper crucible 2 with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com