High-performance polycrystal texture Fe-Ga-based magnetic deformation slice material and preparation method thereof

A magnetostrictive, high-performance technology, applied in the material selection of magnetostrictive devices, the manufacture/assembly of magnetostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the problem of sheet saturation Problems such as small value of magnetostriction coefficient and complicated manufacturing process can achieve high magnetostrictive performance, simple manufacturing process and good texture

Inactive Publication Date: 2010-11-10

UNIV OF SCI & TECH BEIJING

View PDF1 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the above-mentioned studies on Fe-Ga-based flake materials, the common deficiency is that the manufacturing process is too complicated, including cladding of the master alloy, hot rolling, warm rolling and cold rolling. The total number of passes is more than 100. Repeated stress-relief annealing during rolling and the saturation magnetostriction coefficient of the resulting sheet is small

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

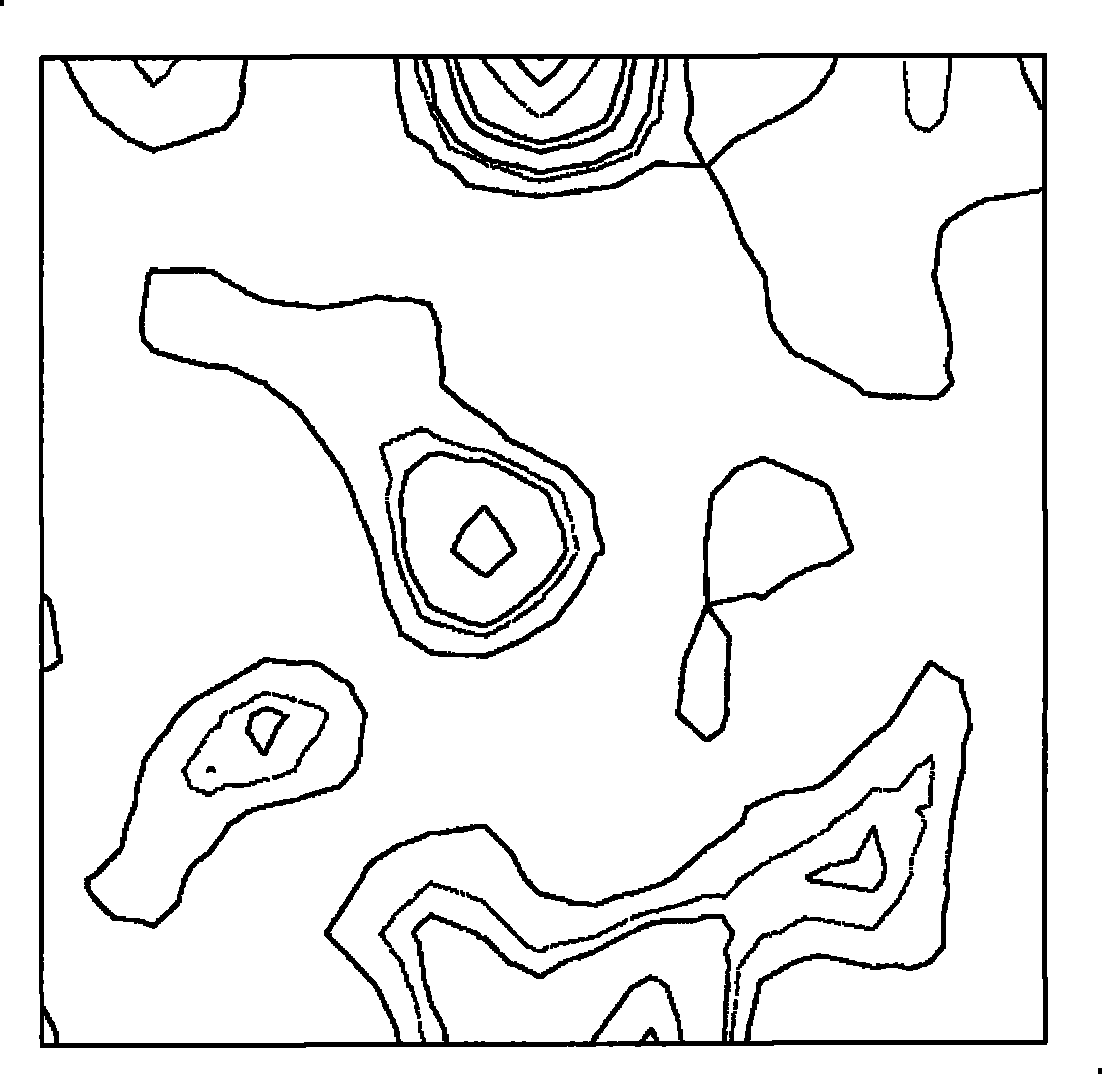

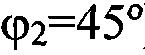

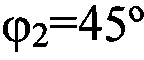

The invention relates to a high-performance polycrystalline texture Fe-Ga-based magnetostrictive thin material and a preparation method thereof; the component of the material is Fe100-x-y-zGaxMyNz; M stands for one or more among B, Nb, Cr, VC, TiC, MnS and AlN; N stands for one or more among S, Sb and Sn; wherein, x is equal to 15-25; y is equal to 0.5-3.0; z is equal to 0.01-0.05; and the residual is iron. The method has the following process key points: based on the requirements of the material composition, melting master alloy; casting alloy ingot; hot-forging and cogging; rolling the material into the appropriate thickness; and a variety of follow-up heat treatment. The Fe-Ga-based magnetostrictive thin material has obvious (100)<001>cubic texture or (110) <001> goss texture; and the maximum magnetostriction coefficient (3 / 2)lambdas is up to 280 multiplying 10<-6>.

Description

High-performance polycrystalline textured Fe-Ga-based magnetostrictive sheet material and its preparation method technical field The invention belongs to the field of magnetic materials, and relates to a high-performance polycrystalline textured magnetostrictive sheet material and a preparation method thereof. Background technique When a ferromagnet is magnetized in an external magnetic field, its length and volume change. This phenomenon is called magnetostriction or magnetostriction effect. Magnetostriction can be divided into linear magnetostriction and volume magnetostriction. Practical magnetostrictive materials refer to materials with linear magnetostrictive properties. The linear magnetostriction or linear magnetostriction coefficient is usually expressed by λ, λ=ΔL / L (L is the original length of the material, ΔL is the change of the sample when the magnetization state changes). When λ>0, it is positive magnetostriction, the ferromagnet elongates in the directi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01L41/20H01L41/22C22C38/00C22C33/06H01L41/47

Inventor 李纪恒何承先高学绪包小倩张茂才

Owner UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com