Method for preparing magnetostriction material by utilizing spent lithium ion batteries

A technology of magnetostrictive materials and lithium-ion batteries, applied in the material selection of magnetostrictive devices, the manufacture/assembly of piezoelectric/electrostrictive devices, battery recycling, etc., to achieve environmental protection, energy saving, high The effect of magnetostrictive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

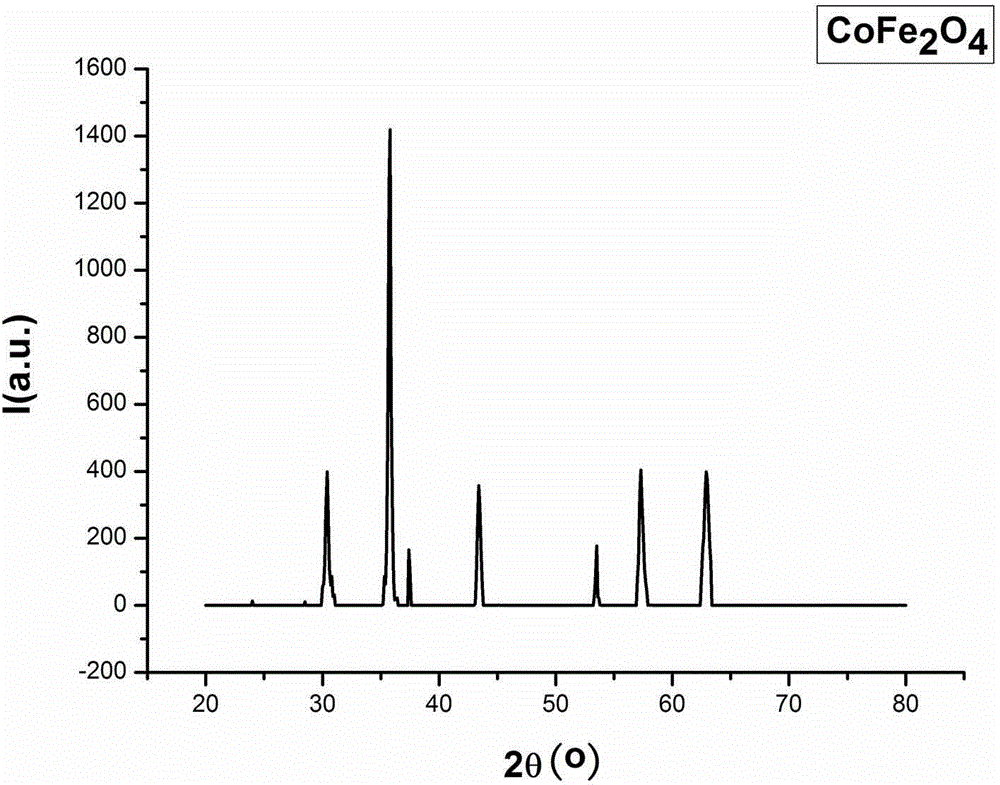

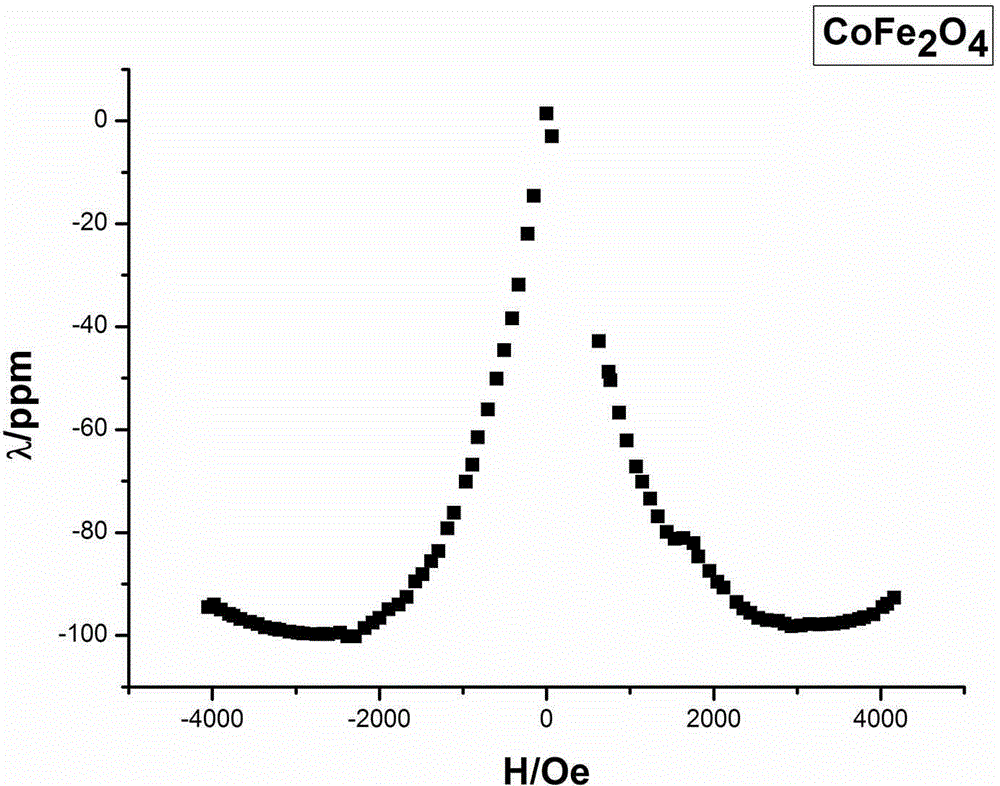

Embodiment 1

[0015] (1) Select the waste lithium-ion battery with lithium cobalt oxide and lithium iron phosphate as the positive electrode material, and leaching the positive electrode active material obtained by dismantling the waste lithium-ion battery with the mixed solution of sulfuric acid / hydrogen peroxide at a solid-to-liquid ratio of 1:4g / mL , after filtering the leaching solution, adjust the pH=9.5 with sodium hydroxide, and completely precipitate the Fe in the filtrate 3+ and Co 2+ , filter and clean the filter residue with deionized water, then dissolve and filter out incompatibles with nitric acid, the molar concentration of sulfuric acid in the sulfuric acid / hydrogen peroxide mixed solution is 3mol / L, and the volume of hydrogen peroxide with a mass concentration of 30% is the same as that of the positive electrode active material The mass ratio is 1:1mL / g;

[0016] (2) Measure the Fe in the filtered nitric acid solution with an atomic absorption spectrophotometer 3+ and Co ...

Embodiment 2

[0021] (1) Select the waste lithium-ion battery with lithium cobalt oxide and lithium iron phosphate as the positive electrode material, and leaching the positive electrode active material obtained by dismantling the waste lithium-ion battery with the mixed solution of sulfuric acid / hydrogen peroxide at a solid-to-liquid ratio of 1:2g / mL , the leaching solution was filtered and adjusted to pH=9 with sodium hydroxide, and the Fe in the filtrate was completely precipitated. 3+ and Co 2+ , filter and clean the filter residue with deionized water, then dissolve and filter out incompatibles with nitric acid, the molar concentration of sulfuric acid in the sulfuric acid / hydrogen peroxide mixed solution is 2mol / L, and the volume of hydrogen peroxide with a mass concentration of 30% is the same as that of the positive electrode active material The mass ratio is 0.5:1mL / g;

[0022] (2) Measure the Fe in the filtered nitric acid solution with an atomic absorption spectrophotometer 3+ ...

Embodiment 3

[0026] (1) Select the waste lithium-ion battery with lithium cobalt oxide and lithium iron phosphate as the positive electrode material, and leaching the positive electrode active material obtained by dismantling the waste lithium-ion battery with the mixed solution of sulfuric acid / hydrogen peroxide at a solid-to-liquid ratio of 1:6g / mL , after filtering the leaching solution, adjust the pH=10 with sodium hydroxide, and completely precipitate the Fe in the filtrate 3+ and Co 2+ , filter and clean the filter residue with deionized water, then dissolve and filter out incompatibles with nitric acid, the molar concentration of sulfuric acid in the sulfuric acid / hydrogen peroxide mixed solution is 4mol / L, and the volume of hydrogen peroxide with a mass concentration of 30% is the same as that of the positive electrode active material The mass ratio is 1.5:1mL / g;

[0027] (2) Measure the Fe in the filtered nitric acid solution with an atomic absorption spectrophotometer 3+ and Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com