High-performance macroscopic foam-state Fe73Ga27 magnetostrictive material and preparation process thereof

A magnetostrictive material, fe73ga27 technology, applied in the direction of material selection for magnetostrictive devices, device material selection, etc., can solve the problem of alloy magnetostrictive strain increase, alloy energy density increase, limit magnetostrictive performance, etc. problem, to achieve the effect of high magnetostrictive coefficient, high yield and excellent magnetostrictive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

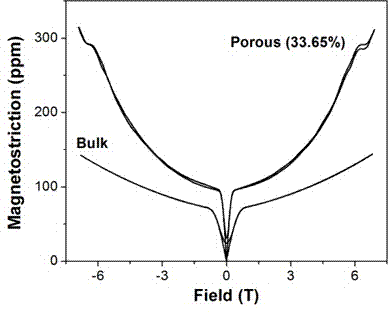

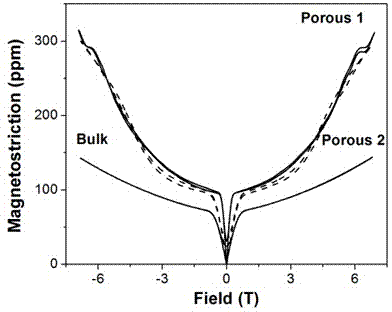

[0038] Example 1: Preparation of foamed Fe with a porosity of 33.65% 73 Ga 27 alloy

[0039] Use an electronic balance to take the raw materials required for the design composition, and add 3wt% more Ga burning loss, with a total weight of 40g, of which 99.99% purity Fe and 99.99% Ga are used, and the prepared raw materials are placed in a vacuum for non-consumption Arc melting furnace.

[0040] Vacuumize the vacuum non-consumable arc melting furnace to 5*10 -3 Pa, flushed into the furnace with 10kPa argon gas, and then vacuumed to 3*10 -3 Pa; the volume percent purity of argon is 99.99%.

[0041] Then fill it with argon to melt to a vacuum degree of 50kPa, and melt the ingredients at a melting current of 100A~150A. The melting time is 5 minutes, and the melting is repeated 5 times to obtain an alloy ingot.

[0042] The purpose of smelting 5 times is to ensure the uniformity of the composition of the alloy ingot.

[0043] Process the alloy ingot into a 6mm*6mm*10mm cub...

Embodiment 2

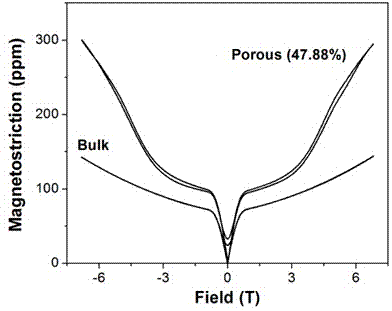

[0051] Example 2: Preparation of foamed Fe with a porosity of 47.88% 73 Ga 27 alloy

[0052] Use an electronic balance to take the raw materials required for the design composition, and add 3wt% more Ga burning loss, with a total weight of 40g, of which 99.99% purity Fe and 99.99% Ga are used, and the prepared raw materials are placed in a vacuum for non-consumption Arc melting furnace.

[0053] Vacuumize the vacuum non-consumable arc melting furnace to 5*10 -3 Pa, flushed into the furnace with 10kPa argon gas, and then vacuumed to 3*10 -3 Pa; the volume percent purity of argon is 99.99%.

[0054] Then fill it with argon to melt to a vacuum degree of 50kPa, and melt the ingredients at a melting current of 100A~150A. The melting time is 5 minutes, and the melting is repeated 5 times to obtain an alloy ingot.

[0055] The purpose of smelting 5 times is to ensure the uniformity of the composition of the alloy ingot.

[0056] Process the alloy ingot into a 6mm*6mm*10mm cub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetostriction coefficient | aaaaa | aaaaa |

| Magnetostriction coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com