Fe-Ga based magnetostrictive wire and preparation method thereof

A magnetostrictive and fe-ga technology, applied in the direction of material selection for magnetostrictive devices, device material selection, etc., to achieve good strength and toughness, improve sensitivity and precision, and high surface quality

Active Publication Date: 2010-08-25

BEIJING MAGORIENTAL MATERIALS TECH CO LTD

View PDF8 Cites 18 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

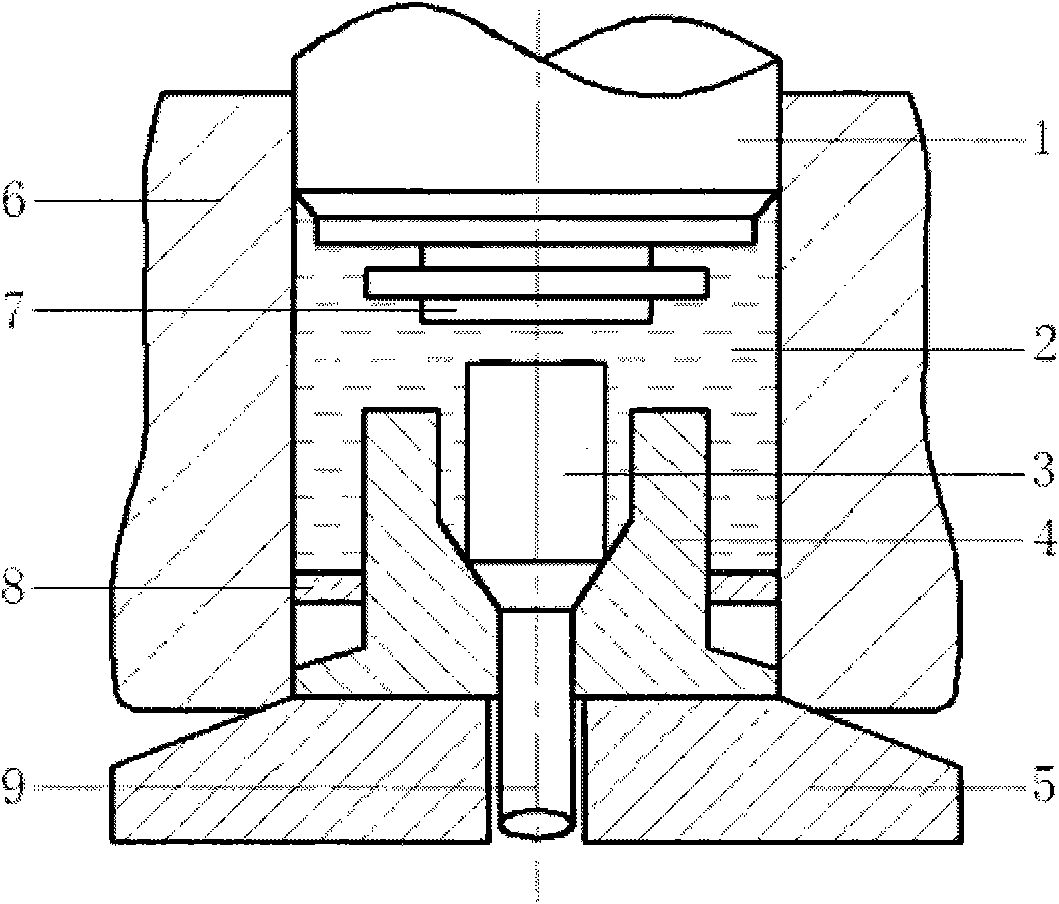

However, for the conventional hydrostatic extrusion method, since the raw material alloy is required to have good plasticity when preparing the metal wire, such as the elongation of the material is required to be greater than 5%, therefore, for Fe-Ga alloys with poor room temperature plasticity, It is difficult to directly use the conventional static night extrusion method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

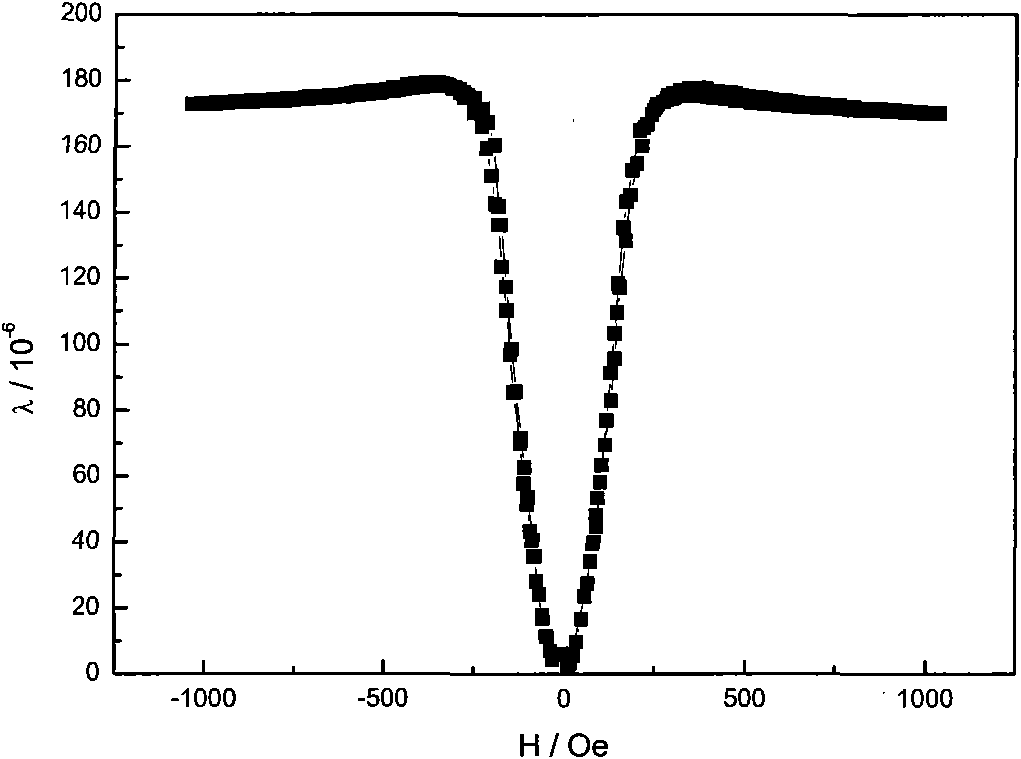

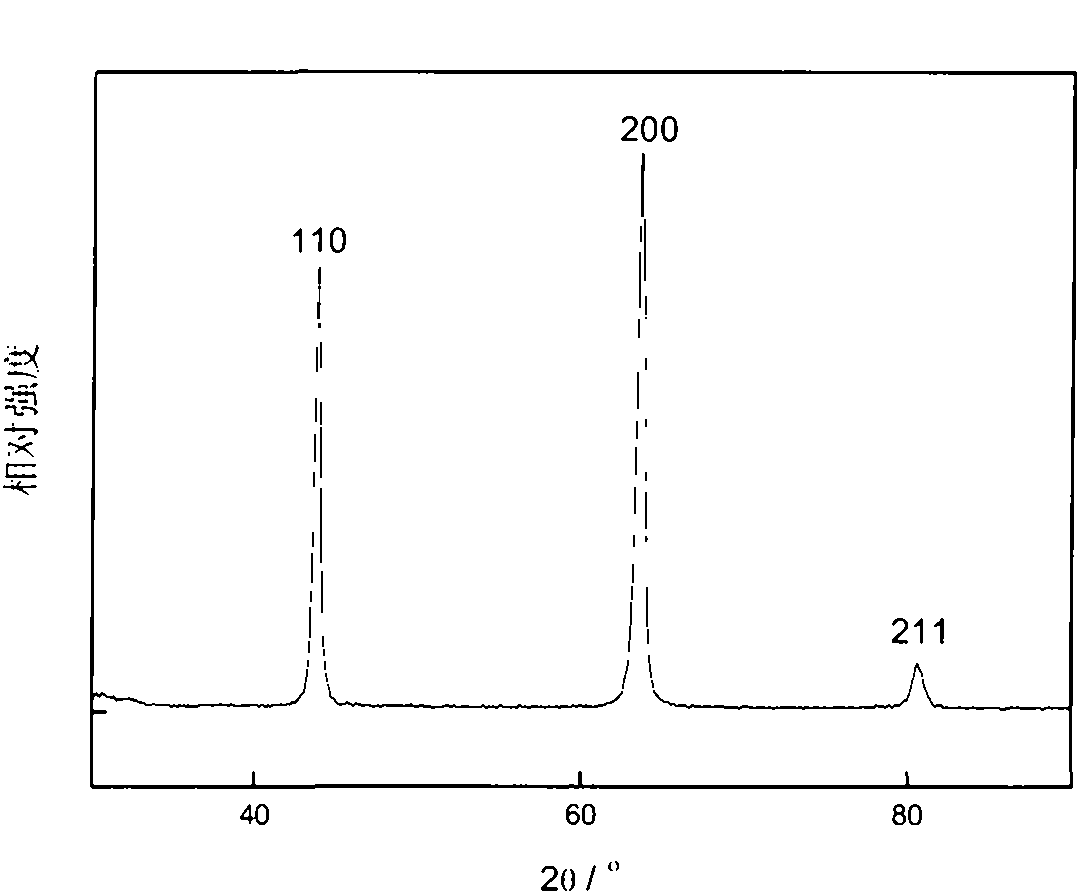

The invention relates to an Fe-Ga based magnetostrictive wire and a preparation method thereof. The raw material component used by the method is (Fel-x-yGaxMy)l-z(NC)z, wherein M is selected from one or more types of all transition elements other than Fe, B, Be, Al, In, Ge, Sn, Sb, Bi, Pb, S and Se, and N is Nb, Ti, Si, Zr, Mo and the like, x is equal to 0.10 to 0.30, y is equal to 0.00 to 0.05, z is equal to 0.00 to 0.02, and the balance Fe. The method processes an Fe-Ga alloy into a finished wire through cold- or warm-hydrostatic extrusion. The invention solves the problems of poor plasticity, larger flow friction resistance and high processing cost when in Fe-Ga alloy plastic processing. The diameter of the prepared Fe-Ga based magnetostrictive wire is between 0.01mm and 2mm, the surface finishment is high, and the magnetostrictive properties under the low-magnetic field environment can reach 180*10-6.

Description

A kind of Fe-Ga base magnetostrictive wire and preparation method thereof technical field The invention belongs to the field of magnetic materials, and relates to a Fe-Ga-based magnetostrictive wire and a preparation method thereof. Background technique As a kind of transducing material, magnetostrictive material has been applied in the field of transducing technology since the 1940s and 1950s. Because when the magnetostrictive phenomenon occurs, a large force can be generated, and the response time is also very short. Later, magnetostrictive materials are also used in technical fields such as driving and sensing. In the field of sensors, including torque sensors, pressure sensors, displacement sensors, etc., magnetostrictive wires are widely used. The common magnetostrictive wires are mostly Fe-Ni, Fe-Ni-Co, etc. These alloys have good plasticity and are good for processing into wires, but the magnetostrictive performance is low, which limits the accuracy and measurement...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/00C22C33/04H01L41/20H10N35/85

Inventor 高学绪李纪恒夏天张茂才周寿增

Owner BEIJING MAGORIENTAL MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com