Fe-Al-B magnetostrictive thin piece material and preparation method thereof

A magnetostrictive, fe-al-b technology, applied in the direction of material selection for magnetostrictive devices, device material selection, etc., can solve the problem of low texture strength, many rolling passes, rolling difficulties, etc. problem, to achieve the effect of simple manufacturing process, reduced number of rolling passes, and simple rolling process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

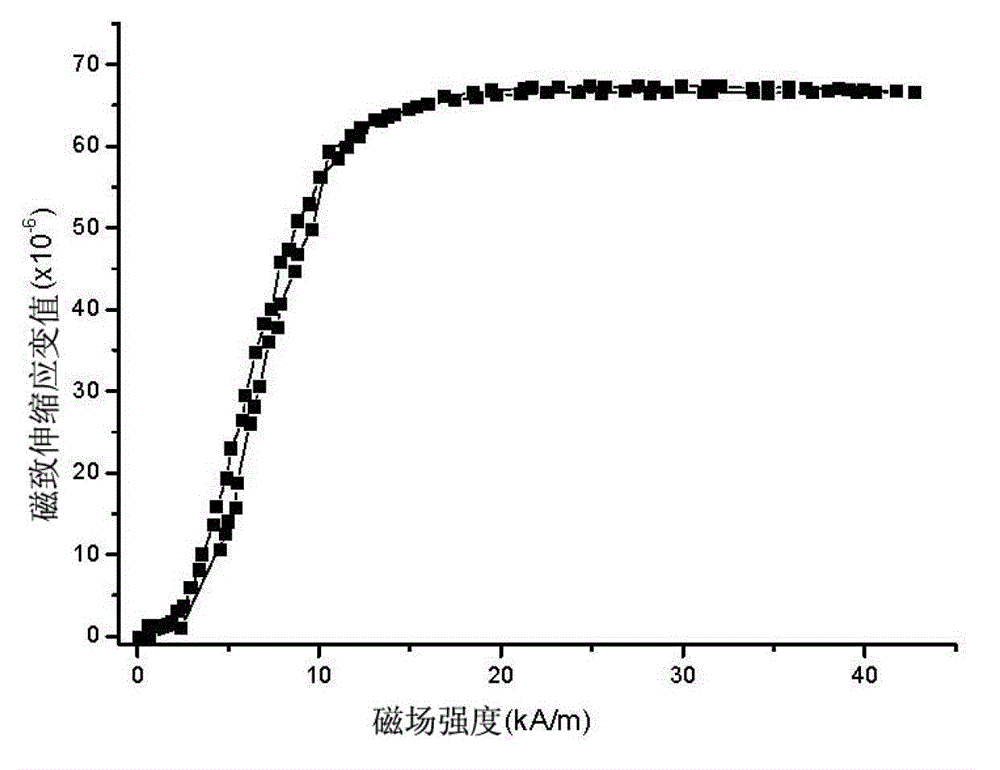

[0034] Example 1: Fe 80.95 Al 19 B 0.05 Preparation of Magnetostrictive Sheet Materials

[0035] The required raw materials are weighed with an electronic balance, and the ingredients are prepared according to the composition of the materials to be prepared. The raw materials used are Fe with a purity greater than 99.99%, Al with a purity greater than 99.99%, and boron-iron master alloys with a purity greater than 99.9%. The master alloy is smelted by vacuum induction melting, and the vacuum is pumped to 8×10 -2 Pa, through argon to keep the vacuum to 5×10 4 Heating after Pa, refining the raw materials for 3 minutes after melting, to ensure the uniformity of the alloy composition, casting the refined alloy into alloy ingots.

[0036] The alloy ingot was forged at 1100°C into a rectangular forging billet with a thickness of about 18mm, so as to be suitable for hot rolling. In practice, there is no special requirement for this thickness. The purpose of forging is mainly to ...

Embodiment 2

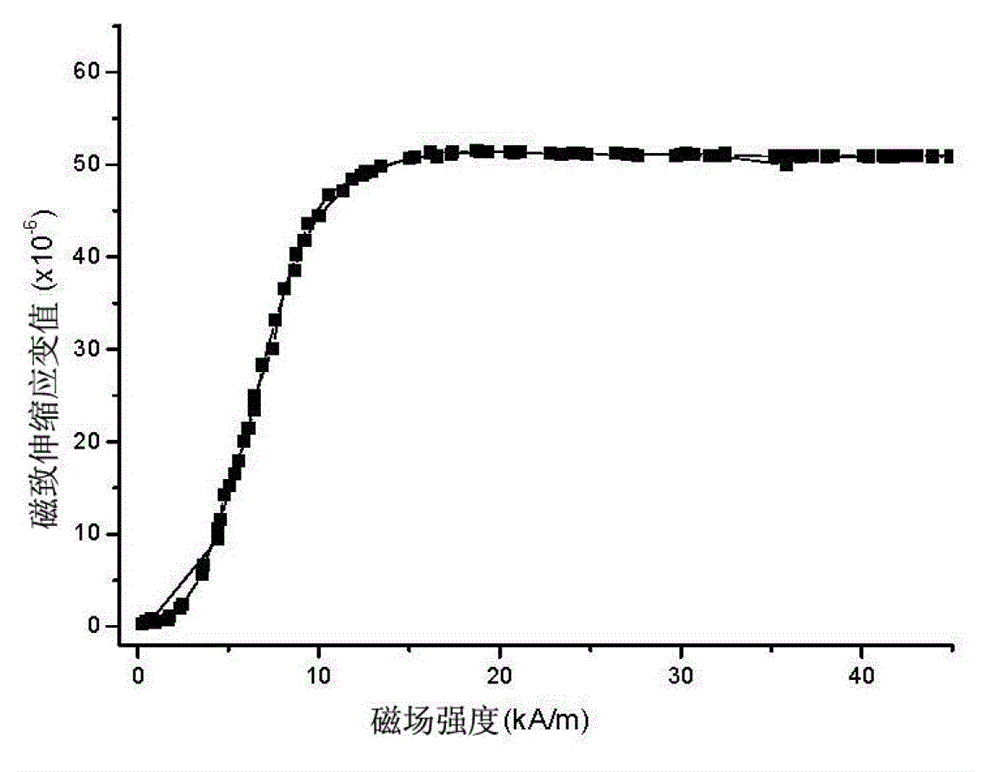

[0040] Example 2: Fe 76.1 Al 23.5 B 0.4 Preparation of Magnetostrictive Sheet Materials

[0041] The required raw materials are weighed with an electronic balance, and the ingredients are prepared according to the composition of the materials to be prepared. The raw materials used are Fe with a purity greater than 99.99%, Al with a purity greater than 99.99%, and boron-iron master alloys with a purity greater than 99.9%. The master alloy is smelted by vacuum induction melting, and the vacuum is pumped to 8×10 -2 Pa, through argon to keep the vacuum to 5×10 4 Heating after Pa, refining the raw materials for 3 minutes after melting, to ensure the uniformity of the alloy composition, casting the refined alloy into alloy ingots.

[0042] The as-cast alloy ingot was forged at 1200°C into a rectangular forging billet with a thickness of about 18mm, so as to be suitable for hot rolling.

[0043] The forged alloy sheet was hot-rolled at a temperature of 1150°C for 6 passes in tot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com