A sort of Fe-Ga magnetostriction alloy wire and preparation method

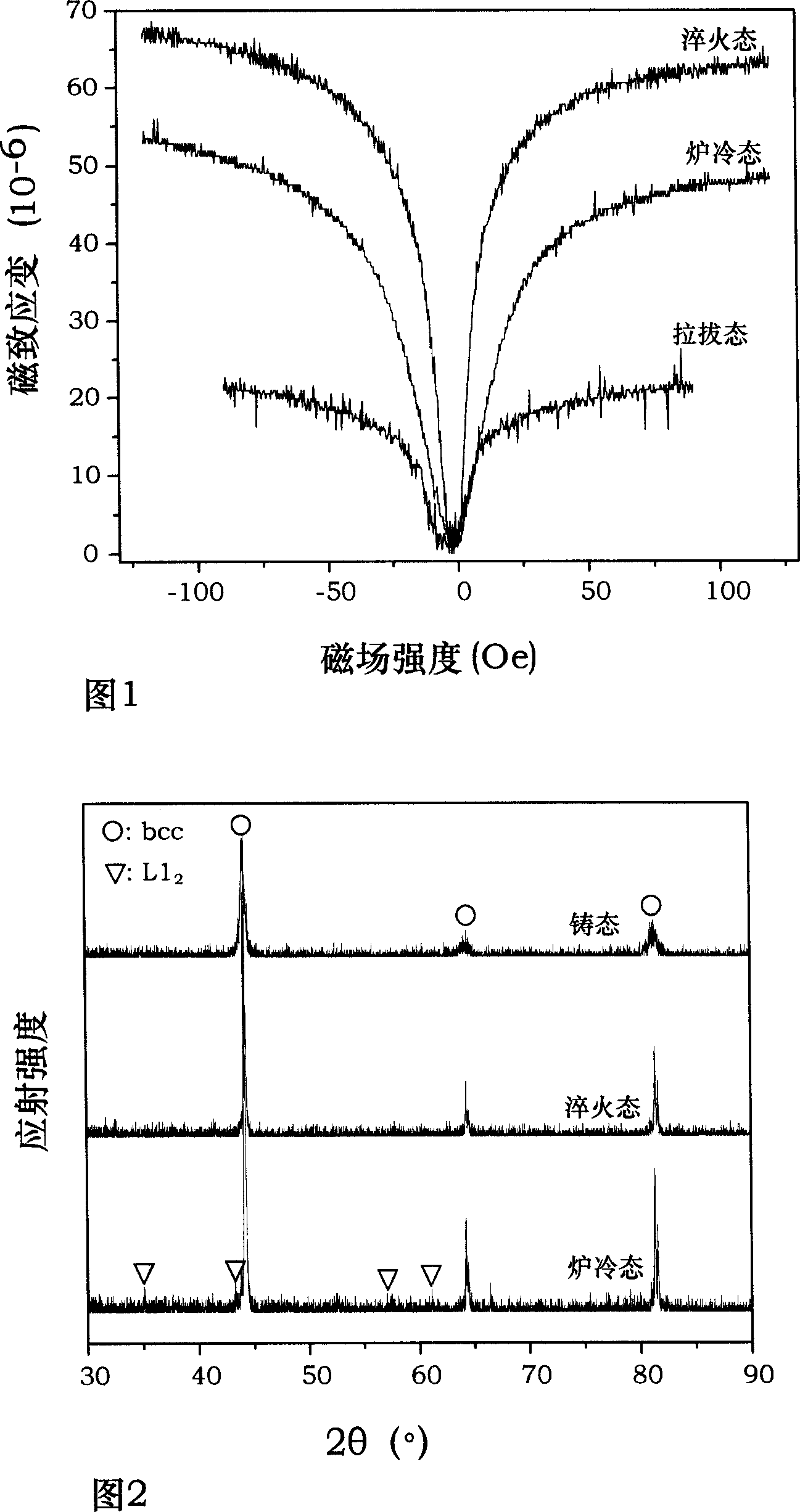

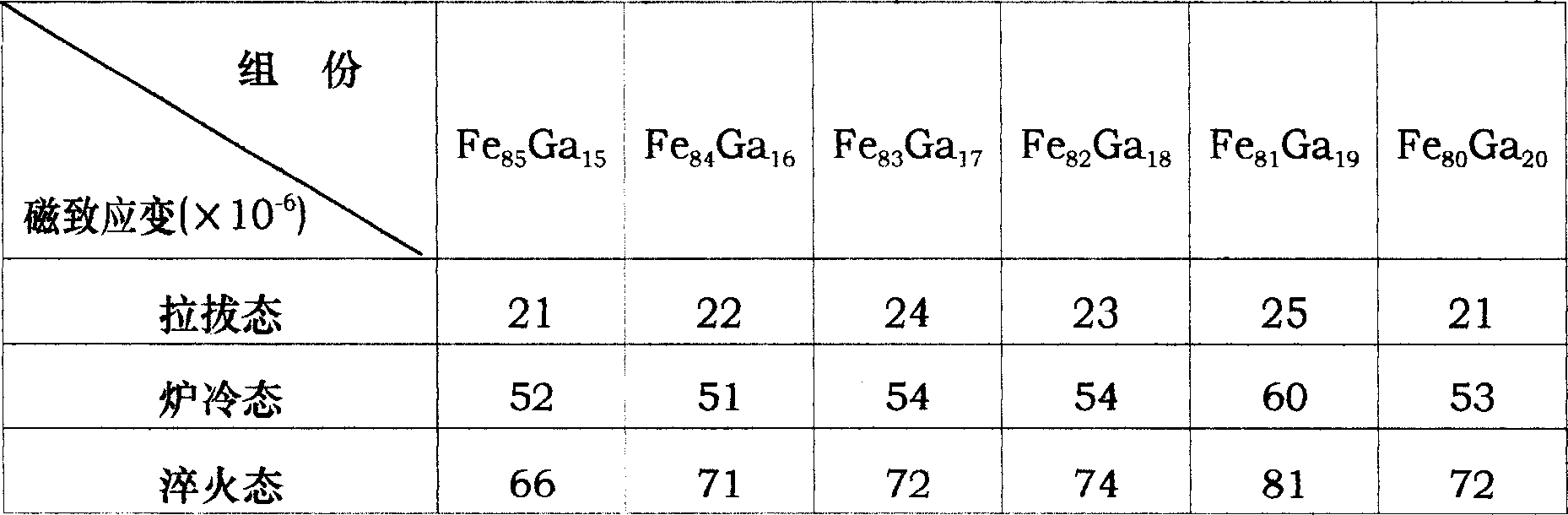

A magnetostrictive, alloy wire technology, applied in other manufacturing equipment/tools, metal processing equipment, manufacturing tools, etc., can solve the problems of low magnetostrictive performance, unfavorable processing and high price, etc., and achieve magnetostrictive performance. Improve, good magnetostrictive performance, reduce the effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1: Manufacture of Fe 85 Ga 15 alloy wire

[0044] Weigh 15at% of Ga with a purity of 99.99%, and the Fe raw material with a balance of 99.99% in purity; put it into a water-cooled copper crucible in a vacuum electric arc furnace, and vacuumize to 2×10 -3 Pa; into the argon, keep the vacuum to 2 × 10 4 Pa, start electric arc smelting Fe and Ga; smelt for 3 minutes until the alloy elements are completely melted, break the arc to form an alloy ingot; turn the ingot over and repeatedly smelt it for 4 times to make the composition of the alloy uniform, and then suction cast it into a 7mm diameter Fe-Ga rod; after cooling, take it out for use;

[0045] Then grind the outer edge of the 7mm Fe-Ga rod on a centerless grinder to obtain a Fe-Ga rod with a smooth surface of about 6.5mm;

[0046] Then, the 6.5mm Fe-Ga rod was hot-swaged at a temperature of 800°C for 3 passes to obtain a 5mm Fe-Ga rod, and the pass feed rate was 0.5mm;

[0047]Then the 5mm Fe-Ga rod was...

Embodiment 2

[0051] Example 2: Manufacture of Fe 82 Ga 18 alloy wire

[0052] Weigh 18at% of Ga with a purity of 99.99%, and Fe raw materials with a balance of 99.99% in purity; put it into a water-cooled copper crucible in a vacuum electric arc furnace, and evacuate to a degree of 2×10 -3 Pa; into the argon, keep the vacuum to 2 × 10 4 Pa, start electric arc smelting Fe and Ga; smelt for 4 minutes until the alloy elements are completely melted, then break the arc to form an alloy ingot; turn the ingot over and repeatedly smelt it for 4 times to make the composition of the alloy uniform, and then suction cast it into a 10mm diameter Fe-Ga rod; after cooling, take it out for use;

[0053] Then grind the outer edge of the 10mm Fe-Ga rod on a centerless grinder to obtain a Fe-Ga rod with a smooth surface of about 9.5mm;

[0054] Then, a 9.5mm Fe-Ga rod was hot-swaged at a temperature of 800°C for 2 passes to obtain a 7.5mm Fe-Ga rod, and the feed rate of each pass was 1mm;

[0055] The...

Embodiment 3

[0058] Example 3: Fe with orientation 85 Ga 15 alloy wire

[0059] Weigh 15at% of Ga with a purity of 99.99%, and the Fe raw material with a balance of 99.99% in purity; put it into a water-cooled copper crucible in a vacuum electric arc furnace, and vacuumize to 2×10 -3 Pa; into the argon, keep the vacuum to 2 × 10 4 Pa, start electric arc smelting Fe and Ga; smelt for 3 minutes until the alloy elements are completely melted, break the arc to form an alloy ingot; turn the ingot over and repeatedly smelt it for 4 times to make the composition of the alloy uniform, and then suction cast it into a 7mm diameter Fe-Ga rod; after cooling, take it out for use;

[0060] Put the obtained Fe-Ga rod with a diameter of 7 mm into a directional solidification high temperature gradient vacuum induction furnace, coat the rod with a corundum tube with an inner diameter of 7.2 mm, and fix it with a clamp. With gallium indium alloy as the cooling liquid, the vacuum degree is 3×10 -3 Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com