Universal gripper using magneto-rheological plastic body

A plastic body, magnetorheological technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of difficult adjustment of grasping force, complex structure, can not be changed, etc., to achieve controllable grasping force, simple structure, improved The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

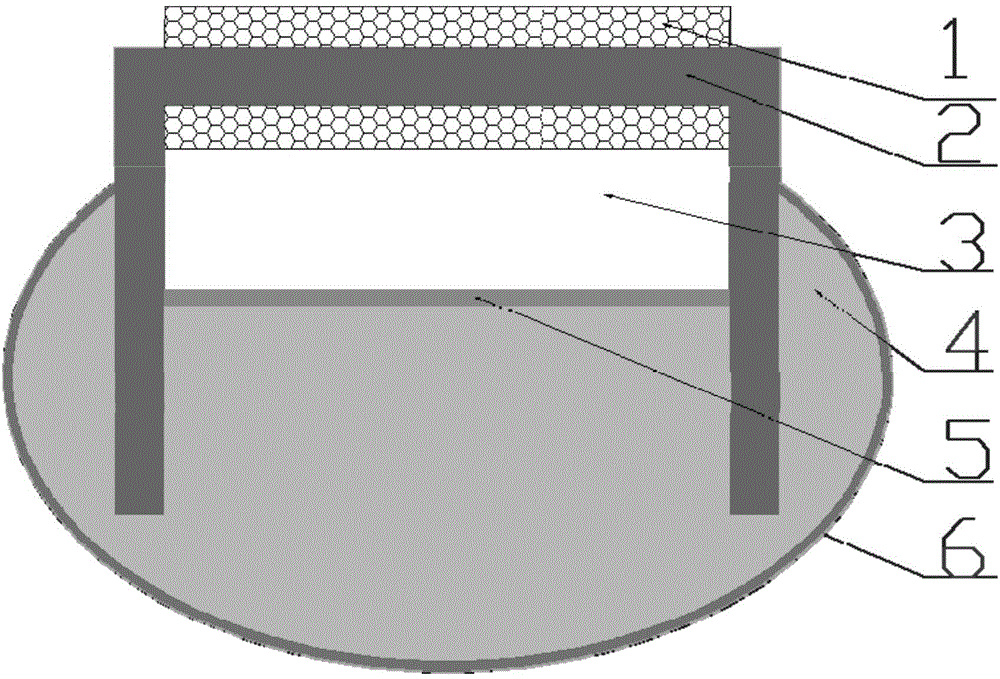

[0013] Such as figure 1 As shown, the universal gripper using magnetorheological plastics includes a U-shaped support frame 2 with a steel magnetic permeable frame as a structural support, and a coil 1 wound in the middle of the U-shaped support frame 2 to generate a magnetic field. An aluminum non-magnetic partition 5 straddling the middle of the U-shaped support frame 2, and a partition 3 between the partition 5 and the U-shaped support frame 2, which can concentrate the magnetic field generated by the coil at both ends below the magnetic permeable frame , while placing the rechargeable battery and the control circuit in the middle of the compartment 3. The outermost is a rubber sleeve 6 with certain elasticity and surface roughness, and the high-performance magnetorheological plastic body 4 is wrapped in it.

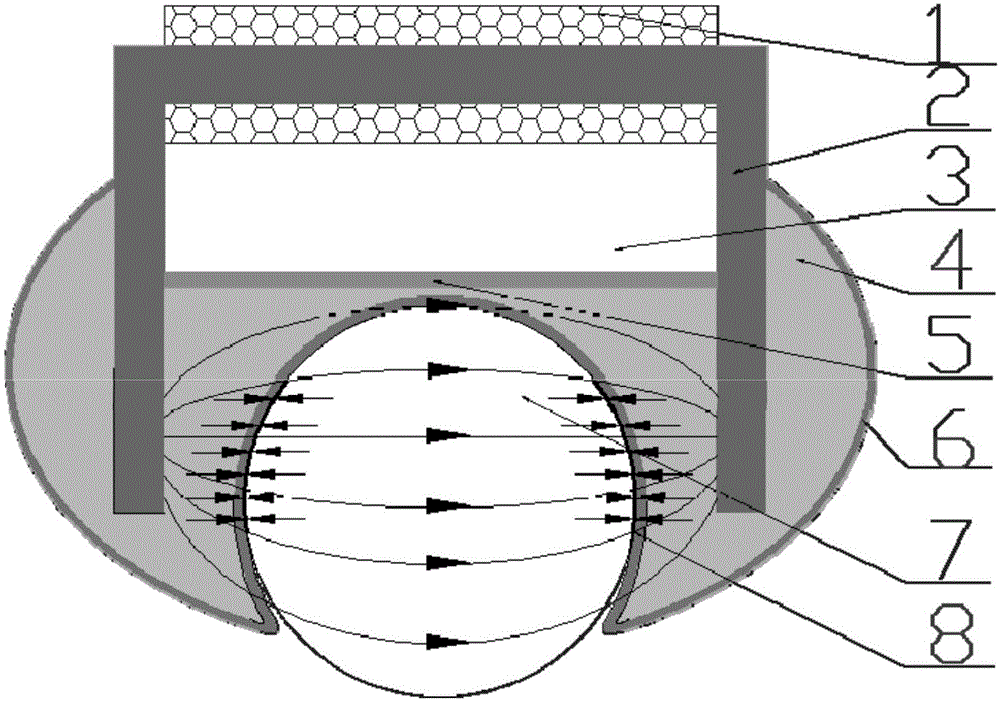

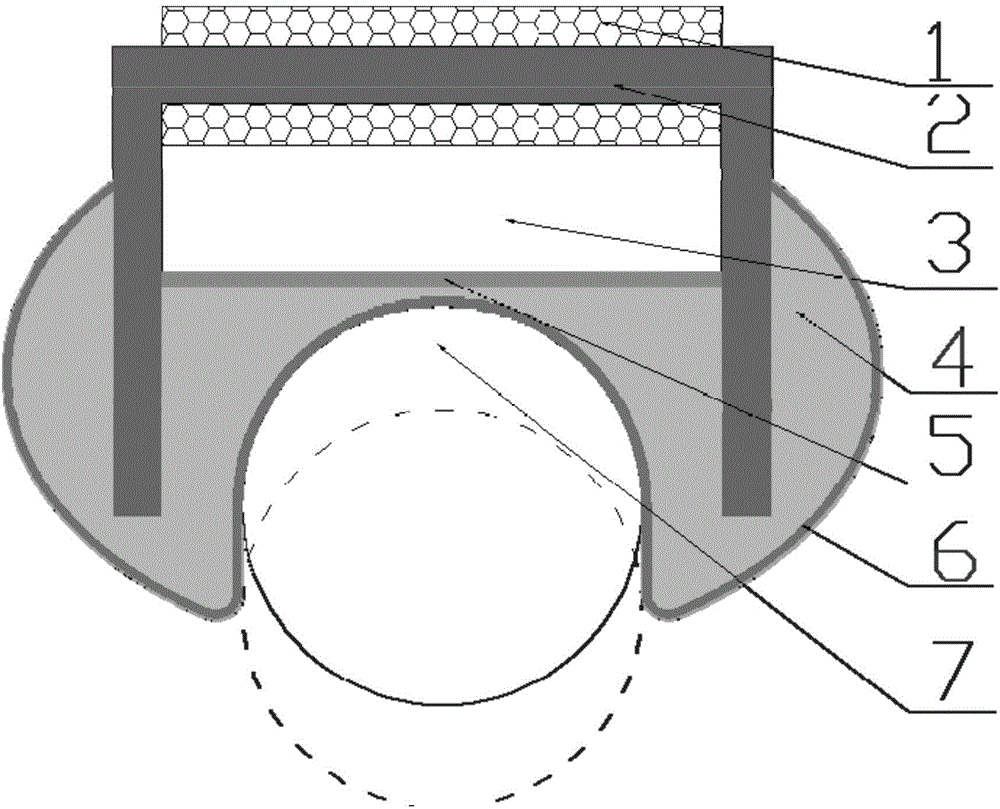

[0014] When the gripper grasps the article, first the gripper is pressed into the object to be grasped by contacting the article 7 . join figure 2 , the number 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com