Preparation of giant magnetostriction alloy wire

A magnetostrictive and alloy wire technology, which is applied in the field of preparation of large magnetostrictive alloy wire, can solve the problems of expensive, difficult to process and shape, limit sensor accuracy and application range, etc., to reduce production costs, cheap, excellent The effect of magnetostrictive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

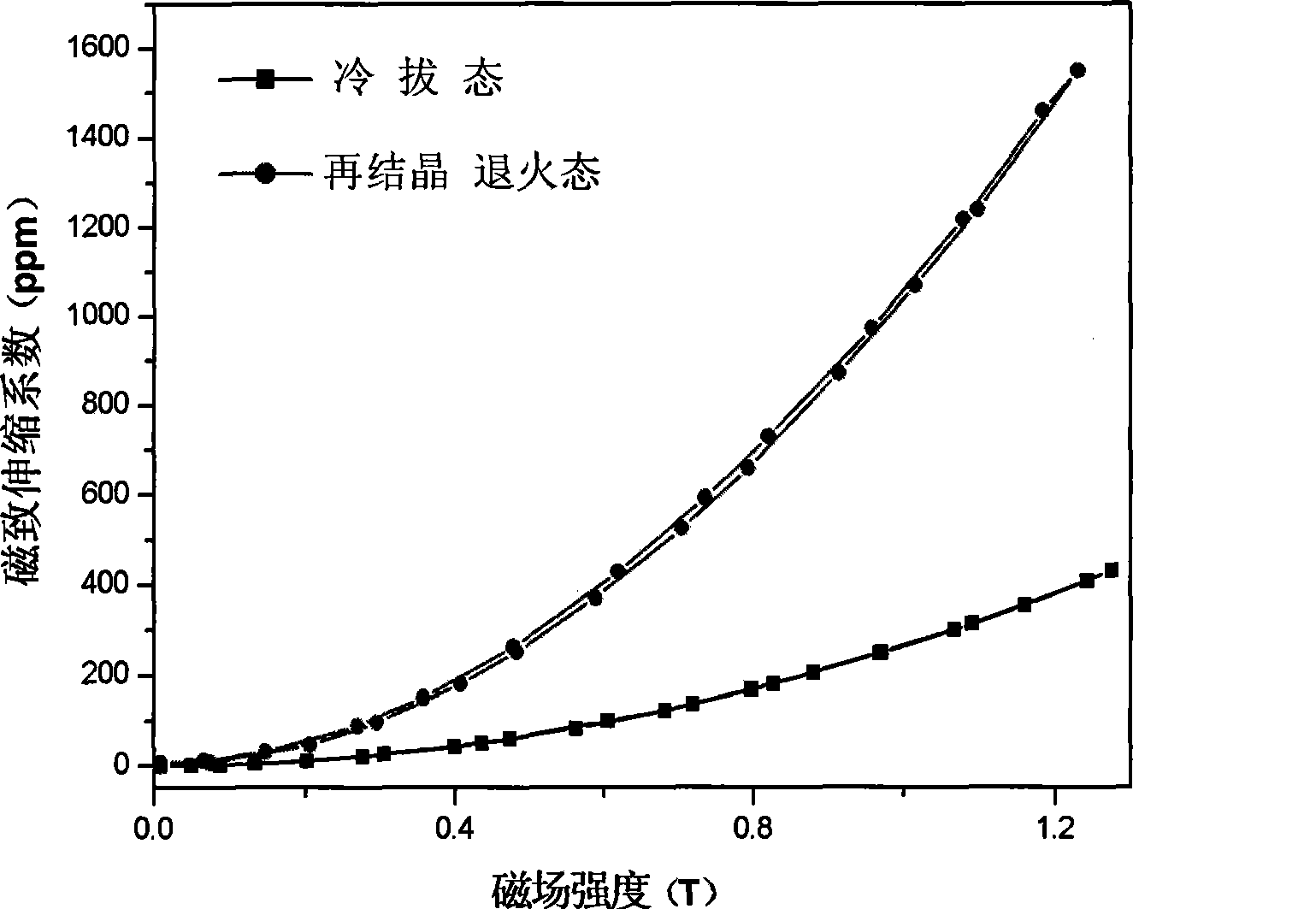

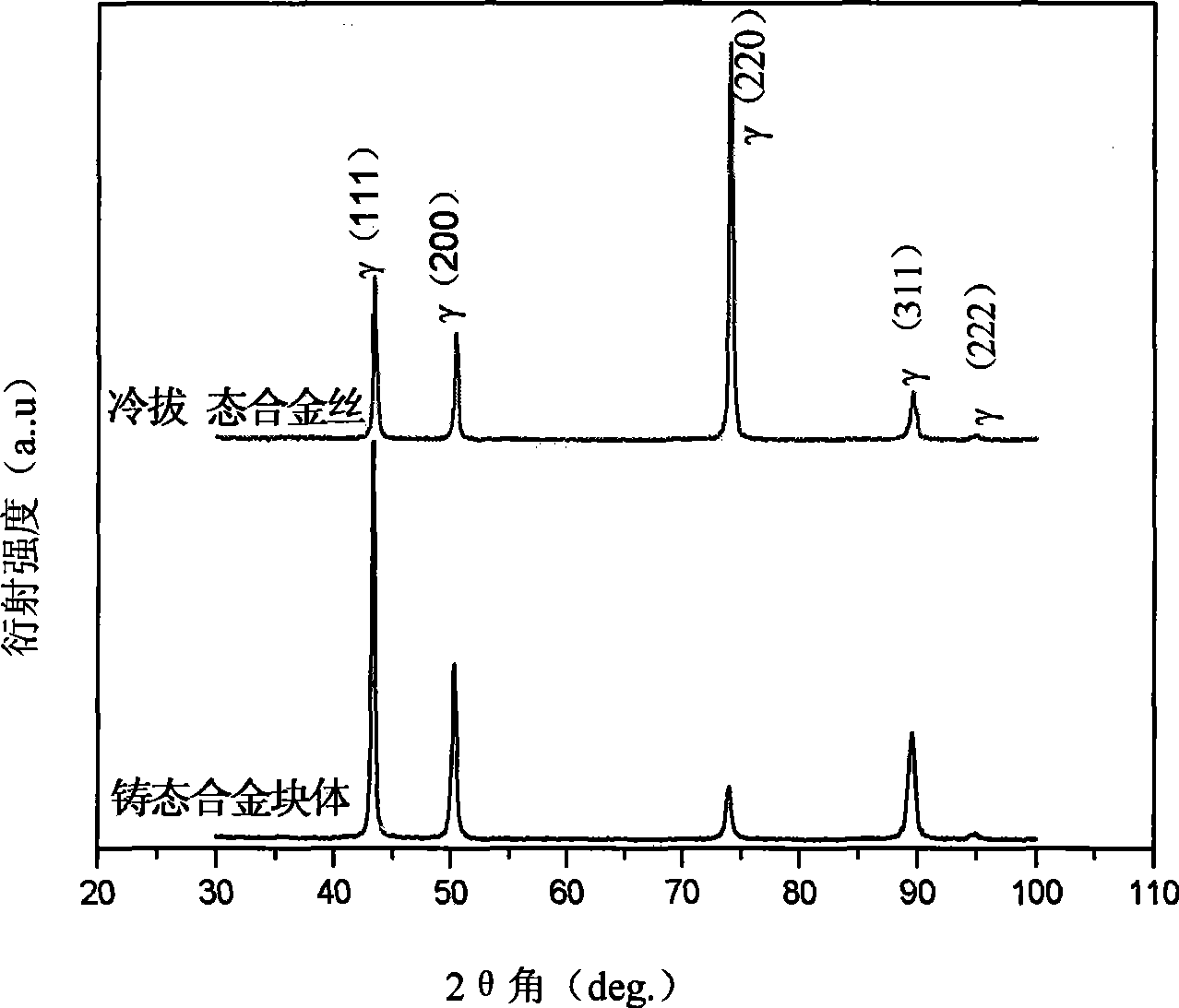

[0035] Example 1: Preparation of Fe with preferred orientation 60 mn 40 Magnetostrictive Alloy Wire

[0036] (1) Smelting and casting rods, weighing Fe and Mn raw materials with a purity of 99.7% according to the atomic percentage of 60:40, putting them into a quartz crucible, and vacuuming to 5×10 -2 ~2×10 -3 Pa, argon gas is introduced as a protective gas, medium frequency heating induction melting, and then cast into Fe with a diameter of 12mm using a copper mold 60 mn 40 Alloy cast rod, ready for use.

[0037] (2) The composition is homogenized, and the Fe after smelting 60 mn 40 The alloy cast rod is placed in a vacuum tube furnace for component homogenization heat treatment, at a temperature of 900 ° C, kept for 120 hours, and cooled in the furnace.

[0038] (3) Milling, Fe after homogenizing the composition 60 mn 40 Alloy cast rods are milled on a milling machine; the cross-section is square and the thickness is 8mm Fe 60 mn 40 alloy rod.

[0039] (4) cold ...

Embodiment 2

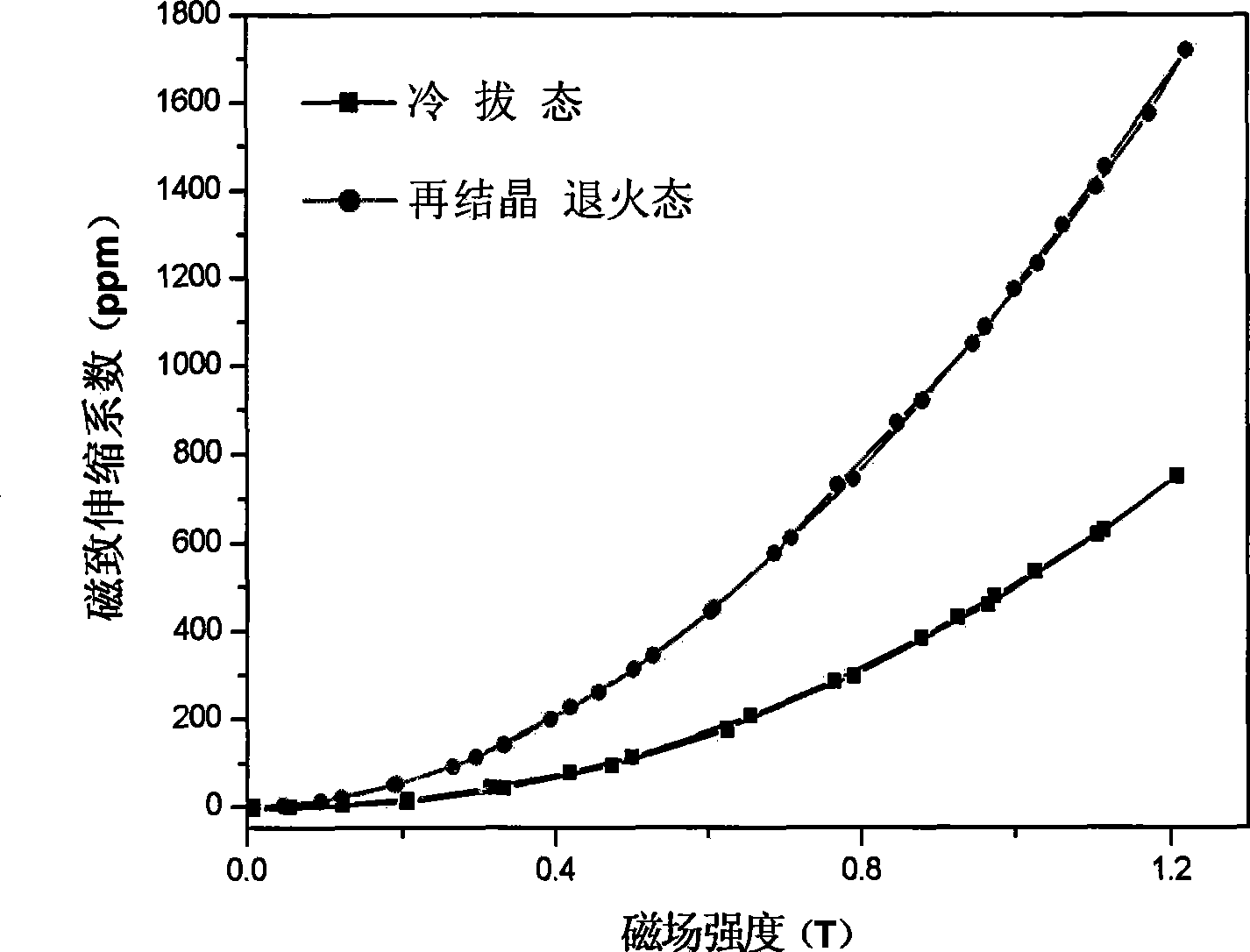

[0045] Example 2: Preparation of Fe with preferred orientation 55 mn 45 Magnetostrictive Alloy Wire

[0046] (1) Smelting and casting rods, weighing Fe and Mn raw materials with a purity of 99.7% according to the atomic percentage of 55:45, put them into a quartz crucible, and vacuumize to 5×10 -2 ~2×10 -3 Pa, argon gas is introduced as a protective gas, medium frequency heating induction melting, and then cast into Fe with a diameter of 14mm using a copper mold 55 mn 45 Alloy cast rod, ready for use.

[0047] (2) The composition is homogenized, and the Fe after smelting 55 mn 45 The alloy cast rod is placed in a vacuum tube furnace for component homogenization heat treatment, at a temperature of 1000 ° C, kept for 24 hours, and cooled in the furnace.

[0048] (3) Milling, Fe after homogenizing the composition 55 mn 45 Alloy cast rods are milled on a milling machine; the cross-section is square and the thickness is 10mm Fe 55 mn 45 alloy rod.

[0049] (4) cold rol...

Embodiment 3

[0055] Example 3: Preparation of Fe with preferred orientation 50 mn 50 Magnetostrictive Alloy Wire

[0056] (1) Smelting and casting rods, weighing Fe and Mn raw materials with a purity of 99.7% according to the atomic percentage of 50:50, put them into a quartz crucible, and vacuumize to 5×10 -2 ~2×10 -3 Pa, argon gas is introduced as a protective gas, medium frequency heating induction melting, and then cast into Fe with a diameter of 20mm using a copper mold 50 mn 50 Alloy cast rod, ready for use.

[0057] (2) The composition is homogenized, and the Fe after smelting 50 mn 50 The alloy cast rod is placed in a vacuum tube furnace for component homogenization heat treatment, at a temperature of 1100 ° C, kept for 168 hours, and cooled in the furnace.

[0058] (3) Milling, homogenizing the composition of Fe after heat treatment 50 mn 50 The alloy casting rod is milled on a milling machine; the obtained Fe 50 mn 50 alloy rod.

[0059] (4) cold rolling, the Fe afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com