Preparation method for magnetostrictive material and magnetostrictive material

A technology of magnetostrictive materials and slurry, applied in the preparation of magnetostrictive materials, in the field of magnetostrictive materials, can solve the problems of complex manufacturing process, high cost, poor magnetostrictive performance, etc., and achieve reduced production costs, magnetic Improvement of stretchability and improvement of flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

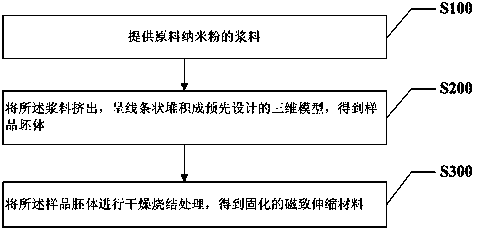

[0030] Preparation method of magnetostrictive material

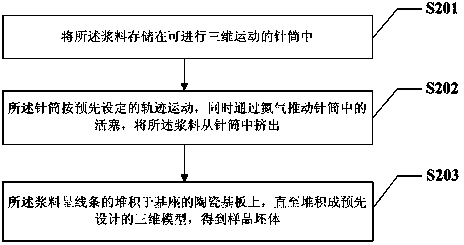

[0031] The present invention uses direct-write molding equipment to implement the preparation method of the present invention. The direct writing molding equipment used in the present invention, for example, can be composed of a molding system and an air pump system located on a three-dimensional motion platform. Among them, the molding system uses a moldless molding platform to prepare three-dimensional structures. The slurry is stored in a syringe, which can move in three-dimensional space, and the two parts are controlled by a microcomputer. When working, the slurry in the syringe is extruded by the high-purity nitrogen gas to push the piston out of the needle, and accumulates on the base in a line shape. According to the diameter of the needle, it can be processed into strips of different diameters. The needle cylinder can move along the x direction and the y direction. After completing a two-dimensional structure,...

Embodiment

[0063] Preparation of Magnetostrictive Materials

[0064] In the illustrated embodiment, the moldless forming platform used is an air-bearing three-dimensional motion platform produced by Aerotech Corporation of the United States. The precision of its own mechanical movement can reach 400nm, which can meet the precision requirements of three-dimensional movement.

[0065] The air pump system adopts the air pump EFD U1traTM 2400 manufactured by A Nordson Company to provide the power to push the piston during molding, and its output air pressure range: 0~689.5kPa. The volume of the syringe used in this example is 30ml, φ22.5mm; the inner diameter of the needle is 0.5mm, and the corresponding working air pressure is controlled between 480~580kPa. on a ceramic substrate.

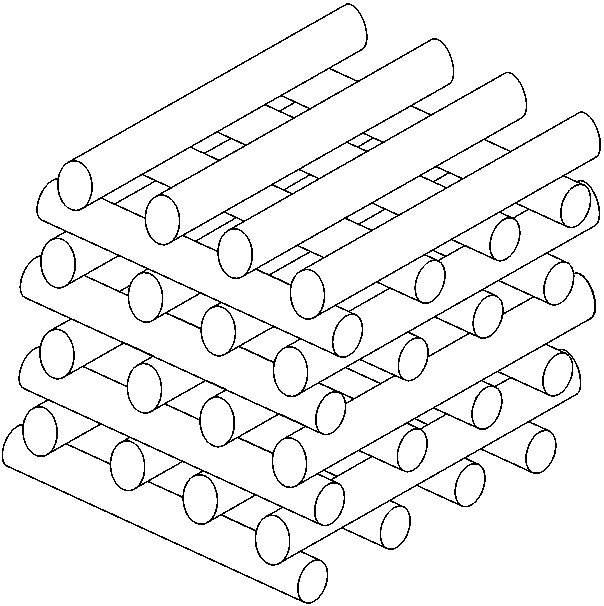

[0066] The pre-designed 3D model is provided by Fe 3 o 4 A 10mm×10mm woodpile structure made of slurry. The woodpile structure has 8 layers, and the distance between adjacent lines on the same layer is 1mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com