Method for improving surface roughness and dimension consistency of wind turbine blade root pultrusion preformed units

A technology of wind power blades and prefabricated parts, which can be applied to household components, climate sustainability, sustainable buildings, etc. It can solve problems such as time-consuming and labor-intensive, reduce bonding strength, and affect the environment, so as to avoid dust pollution and achieve good dimensional consistency , high operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

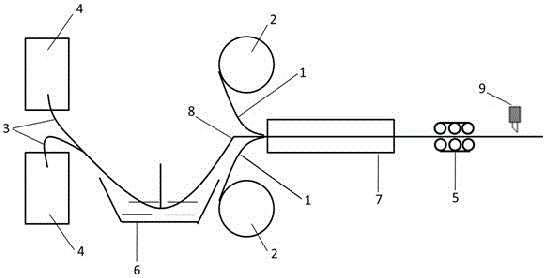

[0058] Such as figure 1 and figure 2 As shown, a method for improving the surface degree and dimensional consistency of the pultruded preform at the root of wind power blades, the steps are:

[0059] (a) Prepare strip-shaped release cloth for ironing (1): cut out strip-shaped release cloth on the release cloth, and perform ironing treatment on both sides of the strip-shaped release cloth;

[0060] (b) Install a release cloth device (2) around the forming mold (7), and place the strip-shaped release cloth (1) that is ironed on the release cloth device (2) in a winding form;

[0061] (c) Arrange the glass fiber yarn (3) on the creel (4), use the pultrusion equipment (5) to pull the glass fiber yarn (3) through the glue tank (6), and then with the long strip of ironing edge The strip-shaped release cloth (1) is pulled into the forming mold synchronously, and the strip-shaped release cloth (1) with ironed edges is attached to the inner surface of the forming mold (7), that is, ...

Embodiment 2

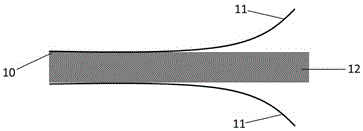

[0066] Same as Example 1, except that the section of the root pultrusion preform is wedge-shaped; the thickness of the release cloth described in step (a) is 0.05mm; the glass fiber yarn described in step (c) It is S glass fiber; the glue tank described in step (c) is equipped with epoxy resin; the heat curing molding described in step (d) is carried out in a molding mold with 5 heating plates inside, and each The temperature of the heating plate can be independently controlled; the pultrusion speed of the pultrusion equipment described in step (d) is 0.1 m / min.

Embodiment 3

[0068] Same as Example 1, except that the section of the root pultrusion preform is triangular; the thickness of the release cloth described in step (a) is 0.15mm; the glass fiber yarn described in step (c) It is H glass fiber; the glue tank described in step (c) is equipped with epoxy resin and vinyl resin; the heat curing molding described in step (d) is carried out in a molding mold with 4 heating plates inside , and each heating plate can be independently temperature controlled; the pultrusion speed of the pultrusion equipment described in step (d) is 0.2 m / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com