Oil pipe supporting hole punching, side turning and blanking continuous die

A technology of blanking and punching, which is applied in the field of cold stamping dies, can solve the problems of high production cost, height that cannot meet technical requirements, and high requirements for external dimensions, so as to improve dimensional accuracy and production efficiency, and the outer surface of the product is beautiful. good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

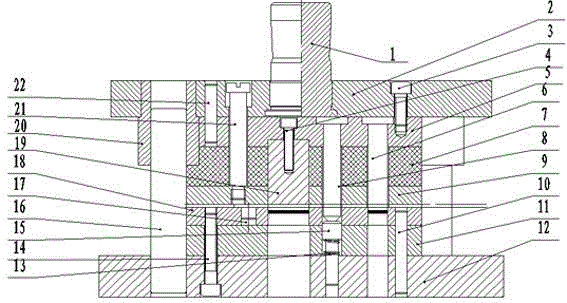

[0032] As shown in the accompanying drawings: a continuous mold for punching, flanging and blanking of oil pipe support, which is composed of an upper mold part and a lower mold part.

[0033] Described patrix part comprises: die handle 1, patrix 2, the I screw 3, the II screw 4, punch fixing plate 5, punching punch 6, unloading rubber 7, flanging punch assembly 8, Unloading plate 9, blanking punch 19, guide sleeve 20, unloading screw 21, the first 1 cylindrical pin 22.

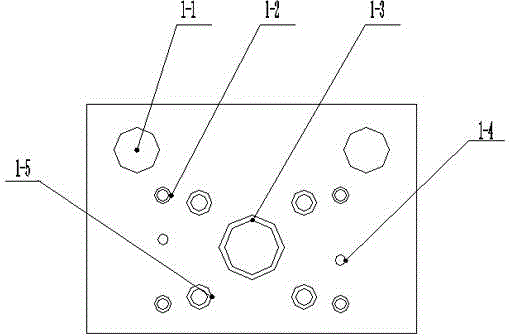

[0034] The upper mold base 2 includes: guide sleeve mounting hole 2-1, punch fixing plate mounting hole 2-2, die handle mounting hole 2-3, punch fixing plate positioning hole 2-4, discharge screw mounting hole 2-5, guide sleeve mounting holes 2-1 are set on both sides above the upper die base, punch fixing plate mounting holes 2-2 are set around the middle of the upper die base, and punch fixing plate positioning holes 2-4 are set on the punch Near the fixed plate mounting hole, the mold handle mounting hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com