Bending and forming die of reinforcing rib plate

A technology for bending forming and ribbed plates, applied in the field of ribbed plate bending forming molds and cold stamping dies, can solve the problems of dimensional accuracy not meeting technical requirements, poor safety and usability, poor appearance quality, etc., to achieve beautiful outer surface of the product, The effect of high production efficiency and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

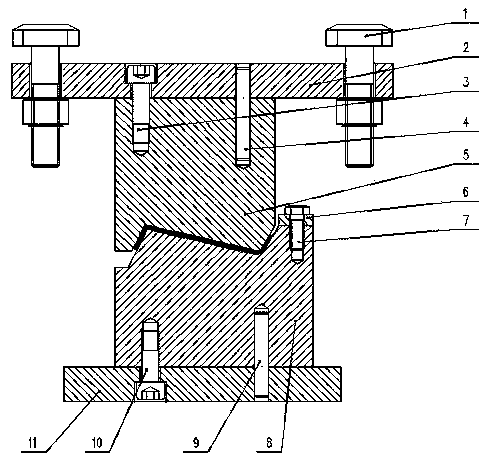

[0025] As shown in the accompanying drawings: a stiffener plate bending forming mold, which includes an upper mold part and a lower mold part.

[0026] The upper mold part includes: a T-bolt assembly 1, an upper mold base 2, an inner hexagon screw 3, a fixing pin 4, and an upper mold 5.

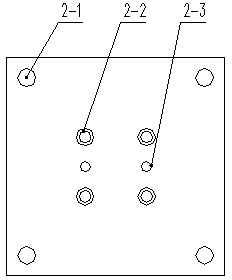

[0027] Described upper mold base 2 comprises: mold base installation hole 2-1, upper mold installation hole 2-2, upper mold positioning hole 2-3, and mold base installation hole 2-1 is located at the periphery of upper mold base, upper Die mounting hole 2-2 is located at the middle of the patrix base, and patrix positioning hole 2-3 is located near the patrix mounting hole.

[0028] Described patrix 5 comprises: the 1st threaded hole 5-1, the 1st positioning hole 5-2, molding top 5-3, the 1st threaded hole 5-1 is located at around the plane above the patrix, the 1st positioning hole 5-2 is located near the 1st threaded hole, and the forming top 5-3 is located under the patrix.

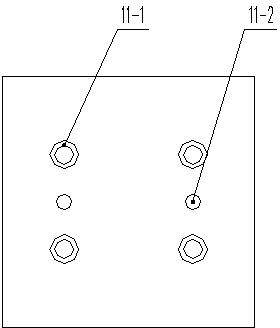

[0029] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com