Automobile swing arm trimming die

A technology of trimming dies and automobile swing arms, which is applied in the field of cold stamping of mechanical processing, can solve the problems of welding process and assembly process, failure to meet process technical requirements, low dimensional consistency, etc., to achieve good dimensional consistency, The effect of low manufacturing cost and stable size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

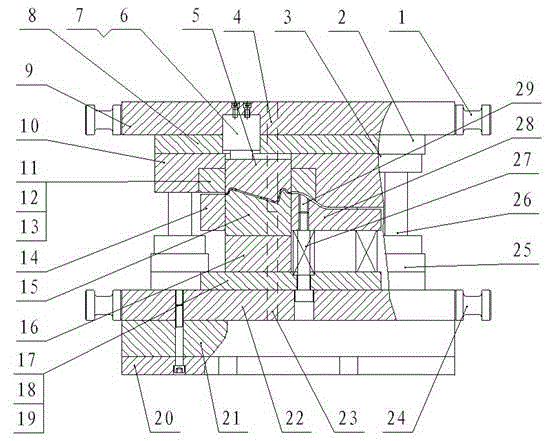

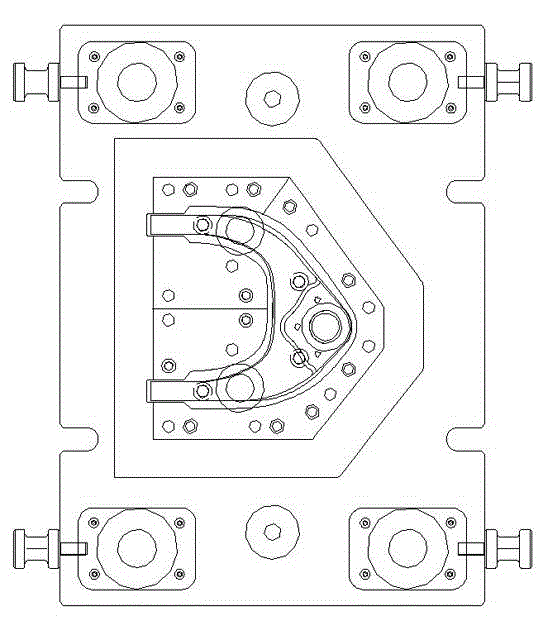

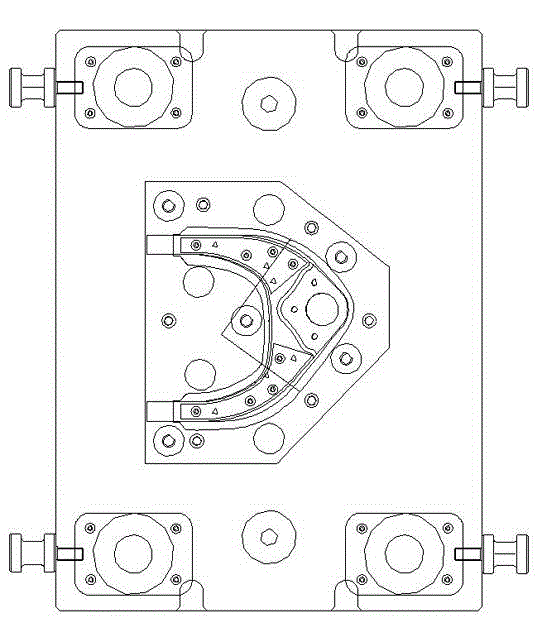

[0028] As shown in the accompanying drawings: an automobile swing arm trimming mold, which includes an upper mold part and a lower mold part.

[0029] The upper mold part includes: upper mold suspension ring assembly 1, guide sleeve fixing seat 2, guide sleeve 3, upper limit assembly 4, binder block 5, ejector spring 6, hexagon socket head cap screw 7, die backing plate 8, The upper die base 9, the die frame 10, the die insert assembly 11, the hexagon socket bolt 12, the positioning pin 13, the upper die base is located at the top of the upper die part, and the four upper die suspension ring assemblies 1 are located on both sides of the upper die base 9 The four corners of the side are connected with the upper die base by bolts, and the four guide sleeve fixing seats 2 are located on the front, rear, left, right and four sides of the upper die base, and are connected with the upper die base by bolts. A guide post 3 is located in the inner hole of the guide sleeve fixing seat 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com