Upper die for integral forming of center frame

A technology of integral forming and center frame, applied in the field of stamping die parts, can solve the problems of not meeting customer requirements, easy to exceed tolerance of processing size, high labor intensity, etc., to achieve beautiful appearance of the product, good dimensional consistency, and low labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

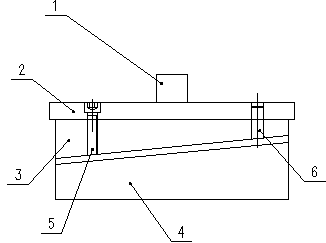

[0017] As shown in the accompanying drawings: an upper mold for integral molding of the center frame, which includes a mold handle 1, an upper mold base 2, an upper mold cushion block 3, a movable forming upper mold 4, bolts 5, and positioning pins 6.

[0018] The die handle 1 is made of round steel with a diameter of 50 mm, and an upper die base connecting mechanism is arranged in the middle of the die handle.

[0019] Described patrix 2 is made by the 1st cuboid, is provided with die handle connection hole in the center of patrix, is provided with patrix cushion block connection installation hole and dowel hole around patrix.

[0020] Described patrix cushion block 3 is made by the II cuboid, is provided with patrix seat mounting bolt hole, active forming patrix connection countersink hole and positioning hole around patrix cushion block, on patrix pad The lower part of the block is provided with a slope.

[0021] The movable forming upper mold 4 is made of the third cuboid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com