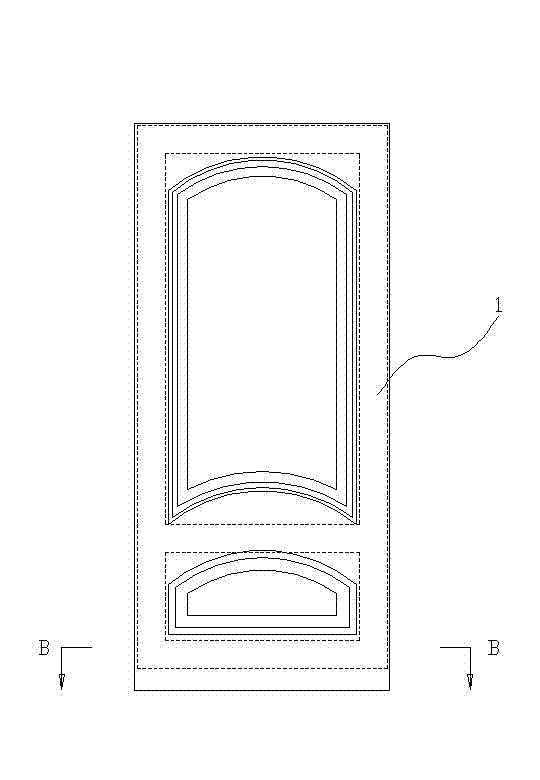

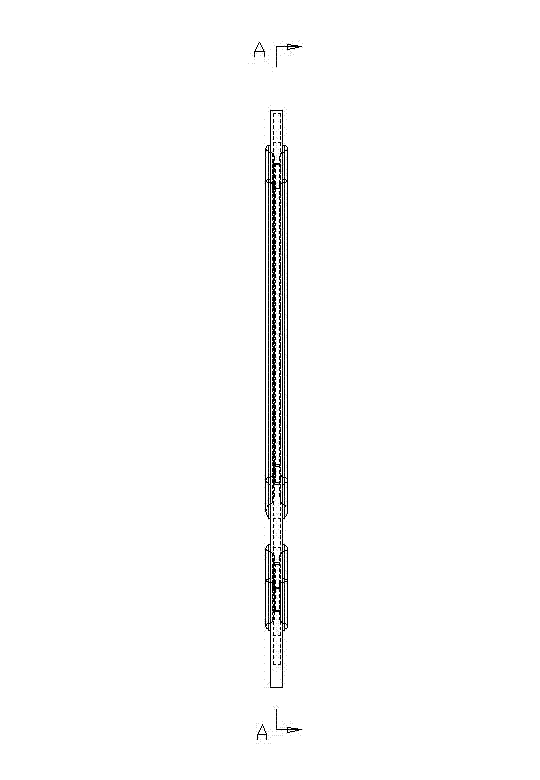

Wood-like polyurethane door and preparation method thereof

A polyurethane and wood technology, applied in the field of polyurethane products, can solve the problems of easy cracking, poor product size consistency, and easy warping or bending of wood-like polyurethane doors, and achieve water resistance, no hygroscopicity, good size consistency, and excellent heat insulation The effect of thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

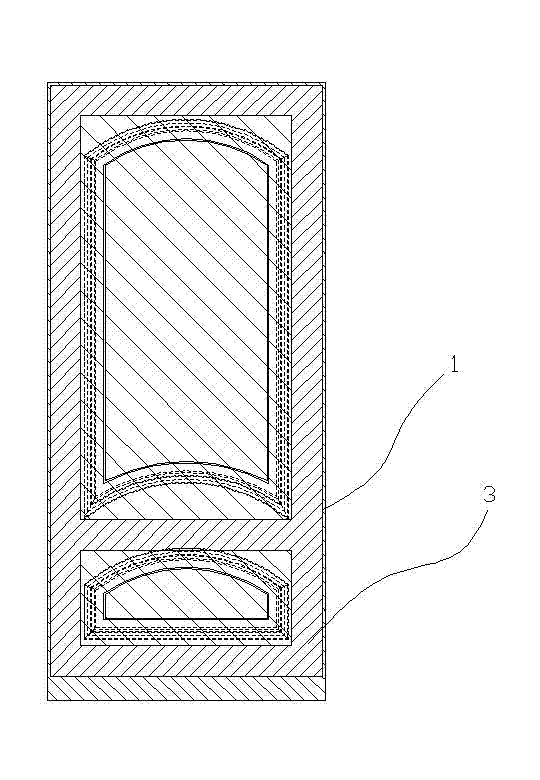

[0023] Example 1: Take the following raw materials and mix them into component A: 300-350 relative molecular mass, 4-6 functional polyether polyol 5 kg; 600-700 relative molecular mass, 4-6 functional polyether polyol 350 kg ; 800-900 relative molecular mass, 4-6 functional polyether polyol 20 kg; catalyst DBU0.05 kg; catalyst pentamethyldiethylenetriamine 0.05 kg for foaming; catalyst four for balance Methylhexamethylenediamine 0.55 kg; flame retardant additive triphosphate 5 kg; flame retardant additive melamine 5 kg; flame retardant additive microcapsule red phosphorus flame retardant 5 kg; foam stabilizing additive Silicone oil 1 kg.

[0024] Among them, the catalyst DBU was purchased from Air Chemical Products Co., Ltd., and the flame retardant additive microcapsule red phosphorus flame retardant was purchased from Shanghai Xusen Non-Halogen Smoke Suppressant Flame Retardant Co., Ltd. The following examples also use the same material. Of course, the same material from o...

Embodiment 2

[0028] Example 2: Take the following raw materials and mix them into component A: 300-350 relative molecular mass, 4-6 functional polyether polyol 15 kg; 600-700 relative molecular mass, 4-6 functional polyether polyol 50 kg kg; 800-900 relative molecular mass, 4-6 functional polyether polyol 40 kg; catalyst DBU 0.15 kg; foaming catalyst pentamethyldiethylenetriamine 0.15 kg; balancing catalyst Tetramethylhexamethylenediamine 1.5 kg; flame retardant additive triphosphate 15 kg; flame retardant additive melamine 10 kg; flame retardant additive microcapsule red phosphorus flame retardant 10 kg; Additive silicone oil 2 kg; foaming agent water 0.5 kg; take 130 kg of polyphenylmethane polyisocyanate (Sup5005) and stir well as component B.

[0029] Then put the pre-processed multi-layer board body 3 into the mold, and then prepare according to the following steps: 1) spray the release agent in the mold; 2) heat the mold to 30-70 degrees, then spray the release agent and put The mul...

Embodiment 3

[0030] Example 3: Take the following raw materials and mix them into component A: 300-350 relative molecular mass, 4-6 functional polyether polyol 8 kg; 600-700 relative molecular mass, 4-6 functional polyether polyol 33 kg; 800-900 relative molecular mass, 4-6 functional polyether polyol 25 kg; catalyst DBU 0.05 kg; catalyst pentamethyldiethylenetriamine 0.1 kg for foaming; catalyst four for balance Methylhexamethylenediamine 0.1 kg; flame retardant additive triphosphate 8 kg; flame retardant additive melamine 8 kg; flame retardant additive microcapsule red phosphorus flame retardant 6 kg; Additive silicone oil 1.5 kg; Foaming agent water 0.2 kg; Take polyphenylmethane polyisocyanate (Sup5005) 115 kg and stir well as component B.

[0031] Then put the pre-processed multi-layer board body 3 into the mold, and then prepare according to the following steps: 1) spray the release agent in the mold; 2) heat the mold to 30-70 degrees, then spray the release agent and put The multi-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com