Machining method of fixed starting point thread

A processing method and starting point technology, applied in metal processing equipment, thread cutting auxiliary equipment, manufacturing tools, etc., to achieve the effect of improving accuracy, reliable processing quality, dimensional consistency and interchangeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail.

[0019] The invention provides a processing method of a thread with a fixed starting point, which specifically includes the following steps:

[0020] S1. Process the outer diameter of the part to the thread state to be processed according to the technical requirements;

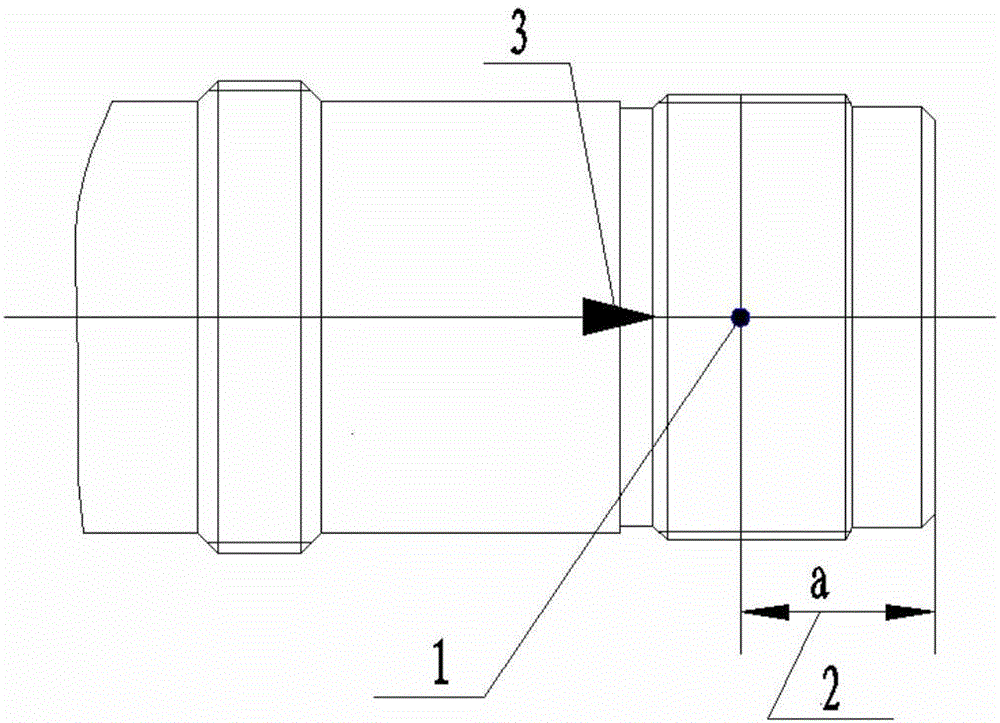

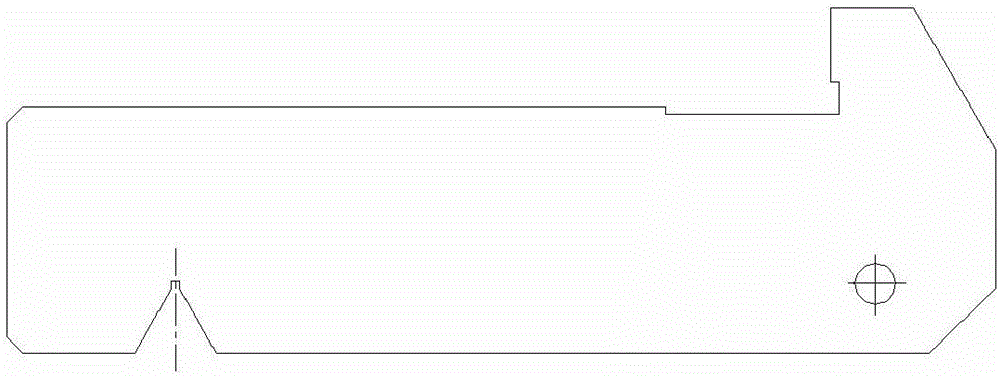

[0021] S2. Axial tool setting: In order to find the position 4 of the starting point of the axial thread, make the angle of the knife edge on the outside of the thread starting template coincide with the angle of the CNC thread turning tool; figure 2 As shown, the thread start template is L-shaped, the thread start template is aligned with the part, and the datum coincides; the outside of the thread start template is provided with a pair of knife edges, and the distance between the pair of knife edges and the reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com