Bidirectional pulse plating switch power source based on complex programmable logic device (CPLD) control

A technology of bidirectional pulse and switching power supply, which is applied in the field of bidirectional pulse electroplating switching power supply based on CPLD control, and can solve problems such as deterioration of coating quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

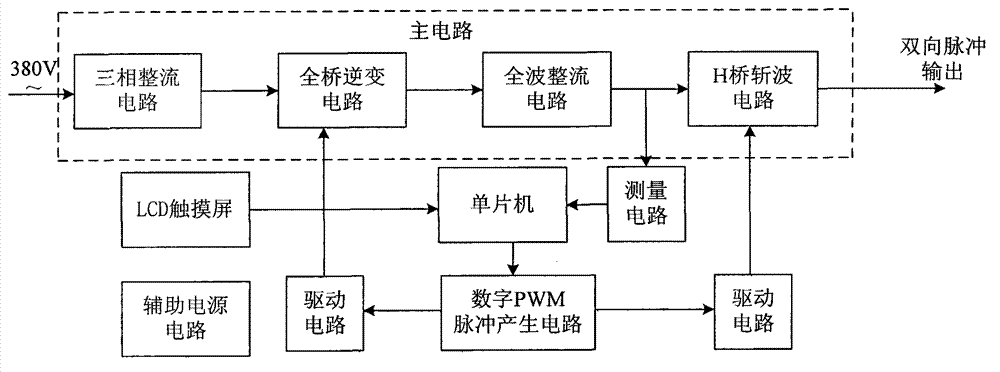

[0019] Depend on figure 1 The system block diagram shows that the bidirectional pulse electroplating switching power supply based on CPLD control includes the main circuit of the power supply, the digital PWM pulse generation circuit, the single-chip microcomputer circuit, the measurement circuit, the LCD touch screen and the power supply. The main circuit of the power supply consists of a three-phase rectifier bridge circuit, an inverter circuit, a full-wave rectifier circuit and an H-bridge chopping circuit, which can realize AC-DC-AC-DC-AC, that is, from three-phase low-frequency (50Hz) alternating current to direct current. , converted to high-frequency (20kHz) AC through the inverter bridge, stepped down to low voltage by high-frequency transformer, full-wave rectified to low-voltage DC to meet the voltage required for electroplating, and finally converted to bidirectional pulse by H-bridge chopper circuit power supply. The measuring circuit measures the magnitude of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com