CuxSe/TiO2 nanotube array of p-type semiconductor nano material and preparation method thereof

A nanotube array and nanomaterial technology, applied in the field of p-type semiconductor nanomaterial CuxSe/TiO2 nanotube array and its preparation, can solve the problems of only absorption, insufficient specific surface area, easy damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

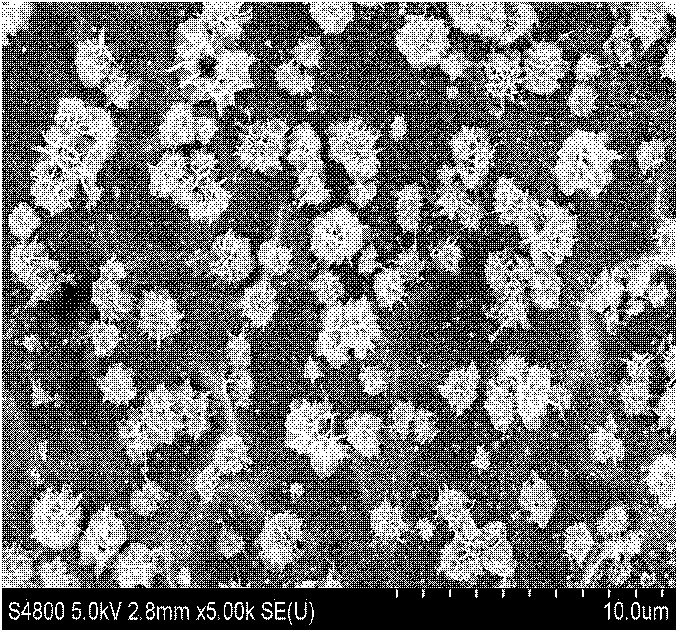

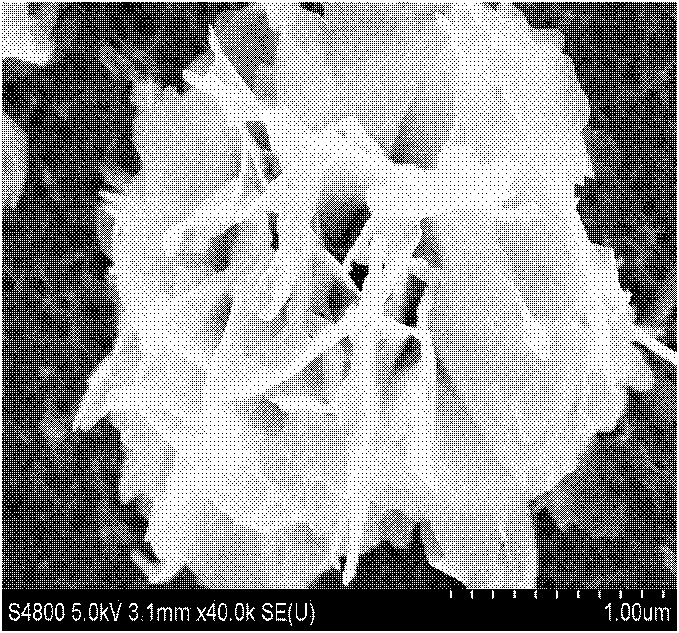

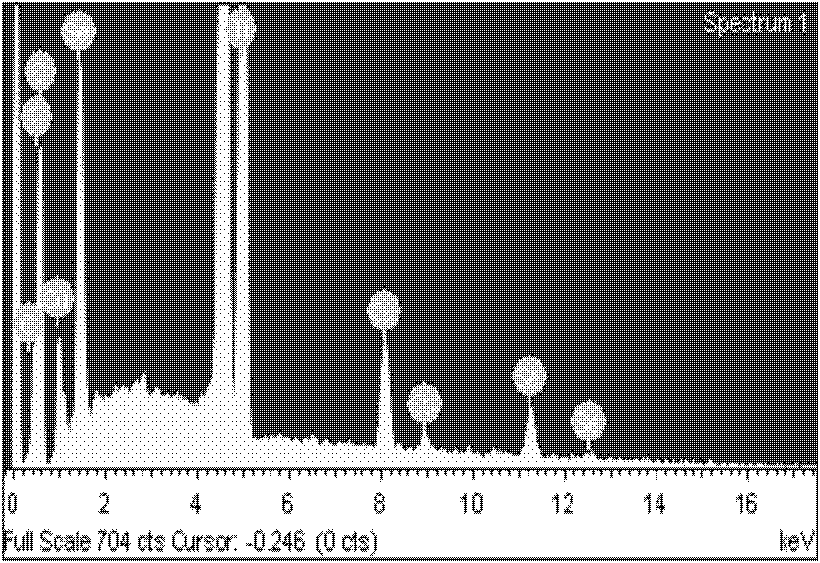

Image

Examples

Embodiment 1

[0023] (1) Grinding the surface of the base material, cleaning it for later use;

[0024] (2) Electrolyte preparation: the electrolyte is composed of hydrofluoric acid with HF mass percentage of 0.5-3% and dimethyl sulfoxide or NH4F with an alcohol solution of 0.25-0.5% by mass;

[0025] (3) Under 25-100V DC voltage, using pure titanium or titanium alloy as the anode and platinum sheet as the cathode, electrolytically prepare titanium oxide nanotubes in the electrolyte;

[0026] (4) Calcining the titanium oxide nanotube array prepared above under aerobic conditions at 400°C-500°C for 4-6h to crystallize it into TiO 2 nanotube arrays;

[0027] (5) adopt the Cu / TiO that step (4) obtains 2The composite nanotube array is the anode, and the platinum sheet is the cathode two-electrode system. The electrode spacing is 2cm, the voltage is 0.5V, and it is electrooxidized in 0.5M-2M NaOH alkaline solution for 30min without stirring to obtain ultrafine Cu. 2 O inner rice noodle modifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com