Transformer station noise reduction method

A technology for substation and noise reduction, applied in the field of noise reduction of substations, can solve the problems of insignificant comprehensive noise reduction effect, inability to meet the noise reduction requirements and service requirements of substations, failure and other problems, and achieve the effect of excellent use reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The invention provides a noise control design method for a newly-built substation. The method is based on general design, referring to station B with the same scheme as station A, and pre-evaluating the noise emission status of station A through the investigation of station B, so as to grasp Spectrum and intensity of the sound source at station A; aiming at the expected control target of noise, new sound-absorbing materials with specific frequency spectrum and advanced simulation technology are adopted, and new sound-absorbing materials are combined with other auxiliary noise reduction measures to control substation noise. The specific program steps are:

[0041] (1) Investigation and evaluation of substation noise:

[0042] Use the sound level meter to measure and analyze the near-field noise of the main sound source equipment in station B and the station boundary noise of the substation, and analyze the noise spectrum characteristics in combination with relevant liter...

Embodiment 2

[0051] 1. Measurement and analysis of substation noise:

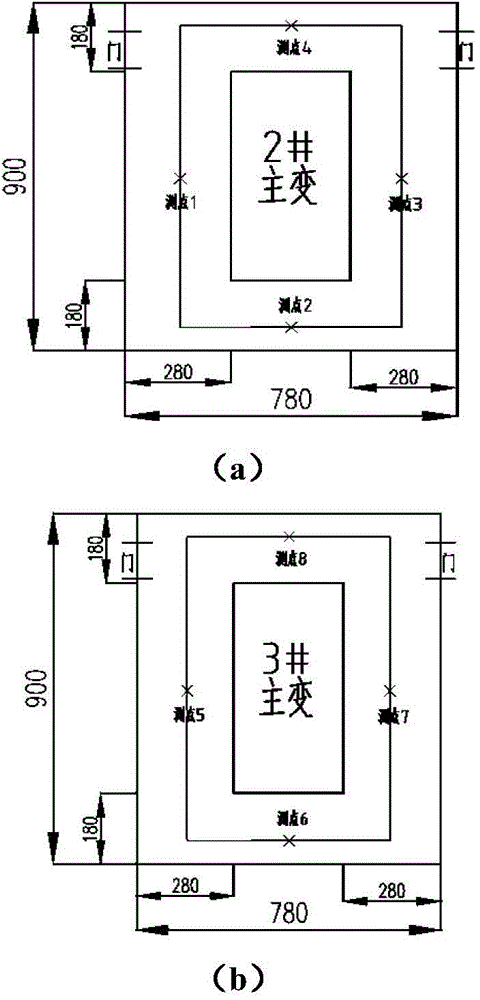

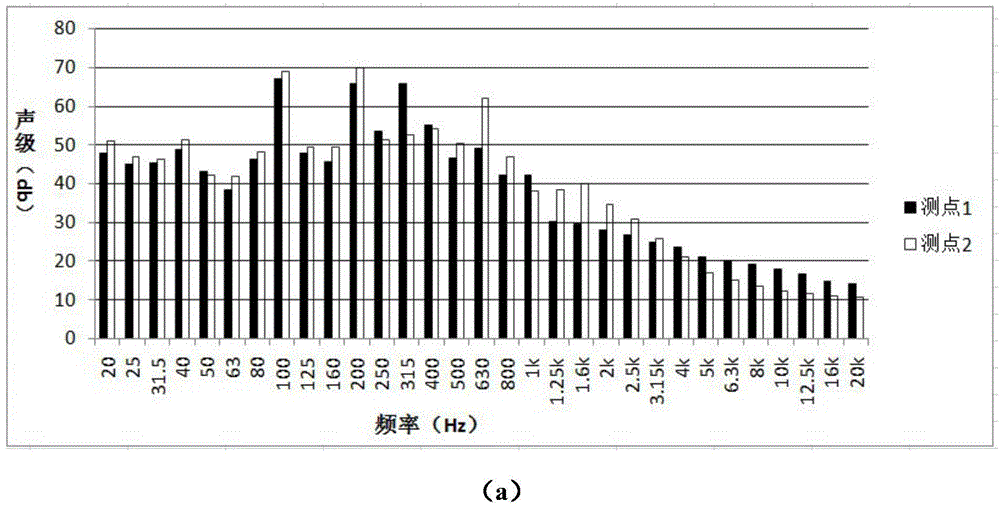

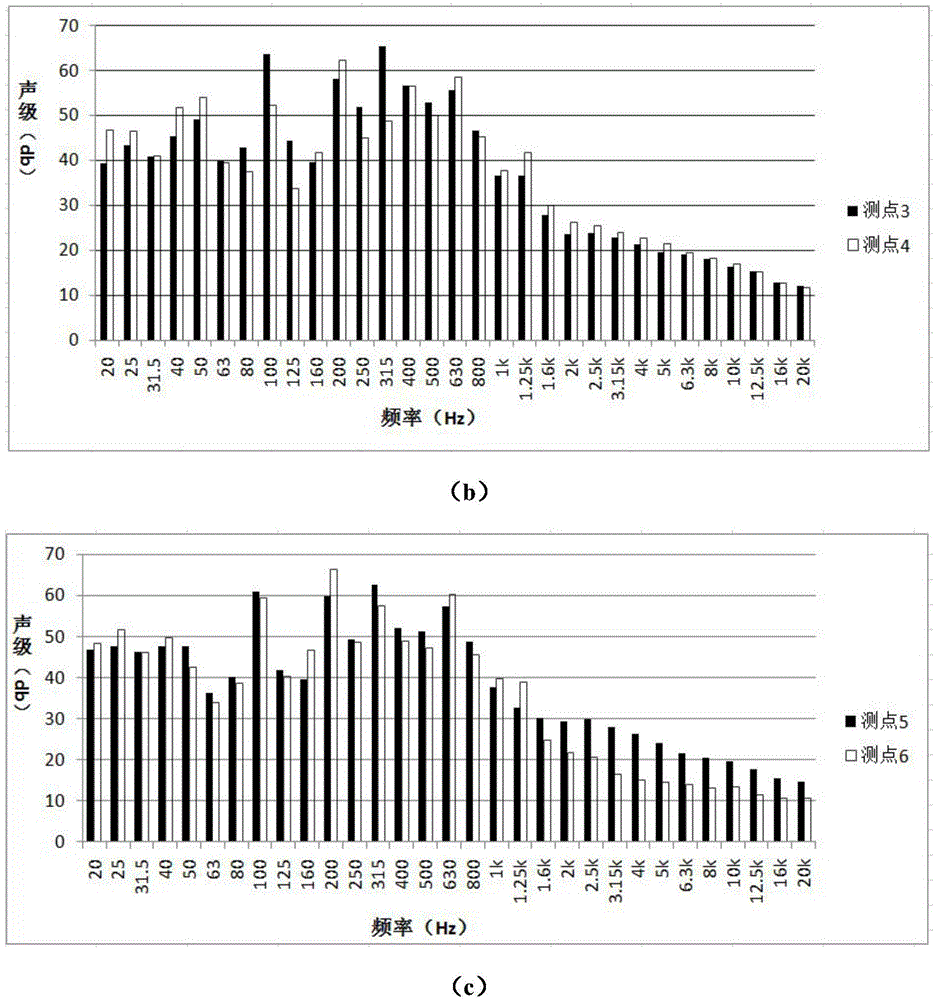

[0052] This project takes station B as an analogy object, and predicts noise emission for station A, so as to grasp the frequency spectrum and intensity of the sound source at station A. The position of the main variable measuring point is as figure 1 Shown (1#, 4# without main transformer). When measuring, the measuring point is 1.5 meters above the ground and 1.5 meters away from the main transformer oil tank shell. figure 2 It is each measuring point spectrogram of main transformer provided by the present invention; Wherein: (a) is the spectrogram of 2# main transformer measuring point 1 and 2; (b) is the spectrogram of 2# main transformer measuring point 3 and 4; ( c) is the spectrum diagram of measuring points 5 and 6 of the 3# main transformer; (d) is the spectrum diagram of measuring points 7 and 8 of the 3# main transformer.

[0053] It can be seen from the noise spectrum that the main noise of this station ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com