Preparation method of magnetic attapulgite surface imprinted hydrophilic nanocomposite

A technology of nanocomposite materials and attapulgite, applied in chemical instruments and methods, magnetic/electric field water/sewage treatment, alkali metal compounds, etc., to achieve uniform distribution, uniform size, and excellent regeneration performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

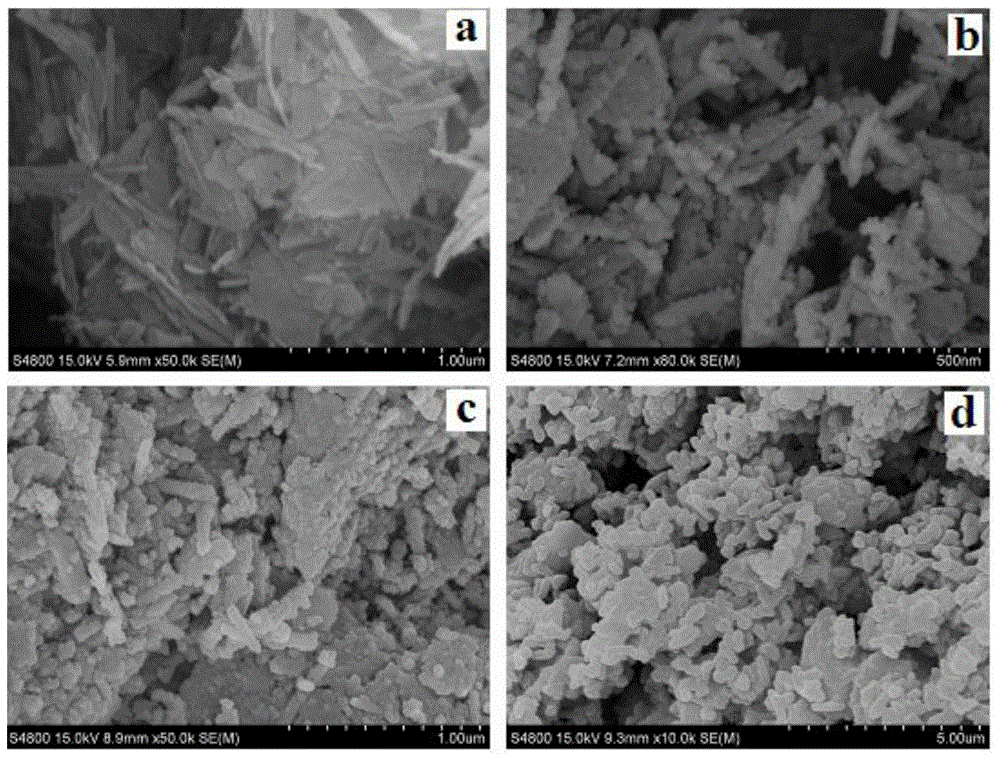

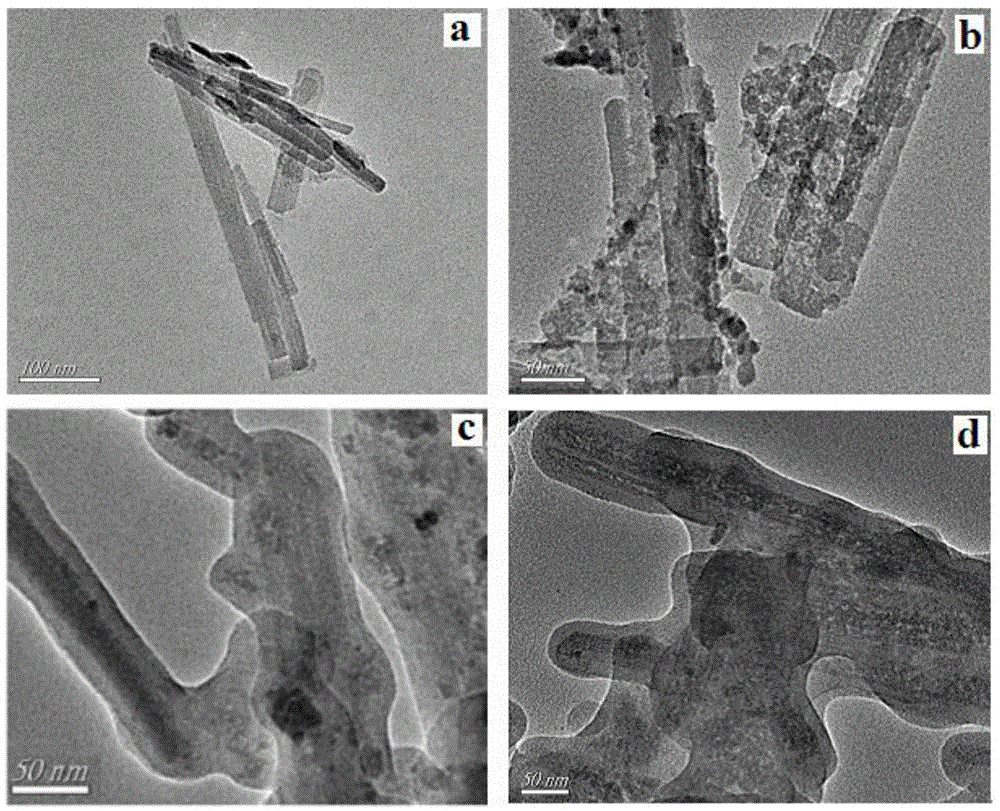

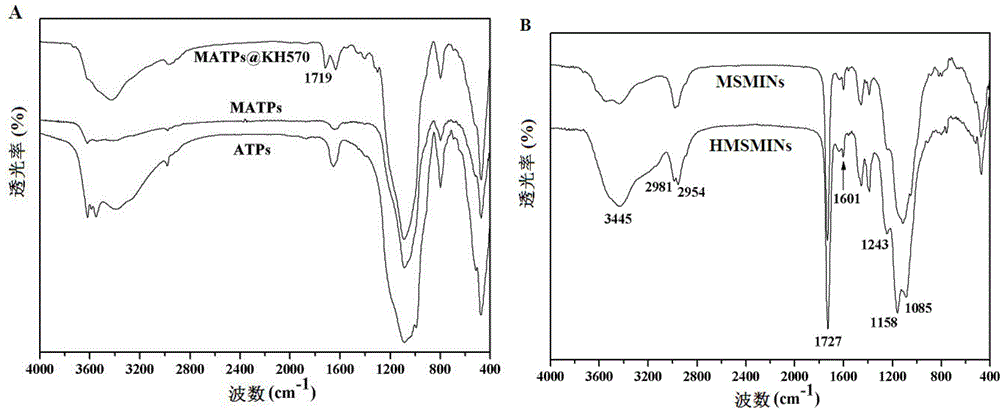

[0031] (1) Preparation of magnetic attapulgite

[0032] According to the mass ratio of ethanol: attapulgite (ATPs): ferric nitrate nonahydrate is 20:0.5:0.4 (g / g / g), add ethanol, attapulgite and ferric nitrate nonahydrate successively to the flask, ultrasonic Disperse evenly, stir magnetically at room temperature for 12h, place at 60 o C oven dry. After grinding, put it into a magnetic boat, add a sufficient amount of ethylene glycol (EG) dropwise, fully soak for 12 hours, and heat it in a tube furnace at 3.0 o C / min heating up to 300 o C, maintaining the temperature for calcination for 1.0 h, and the calcined product was washed with ethanol several times, and then dried to constant weight to obtain magnetic attapulgite (MATPs).

[0033] (2) Preparation of vinyl-functionalized magnetic attapulgite

[0034] According to the ratio of magnetic attapulgite: 3-(methacryloyloxy)propyltrimethoxysilane (KH570): toluene mass ratio of 1.0:1.0:100 (g / g / g), add to the three-necked fla...

Embodiment 2

[0040] (1) Preparation of magnetic attapulgite

[0041] According to the ratio of ethanol: attapulgite (ATPs): ferric nitrate nonahydrate mass ratio of 20:2.0:1.0 (g / g / g), add ethanol, attapulgite and ferric nitrate nonahydrate to the flask successively, ultrasonic Disperse evenly, stir magnetically at room temperature for 18h, place at 80 o C oven dry. After grinding, put it into a magnetic boat, add a sufficient amount of ethylene glycol (EG) dropwise, and fully soak for 12 hours. o C / min heating up to 500 o C, maintaining the temperature for calcination for 3.0 h, and the calcined product was washed with ethanol several times, and then dried to constant weight to obtain magnetic attapulgite (MATPs).

[0042] (2) Preparation of vinyl-functionalized magnetic attapulgite

[0043] According to the ratio of magnetic attapulgite: 3-(methacryloyloxy)propyltrimethoxysilane (KH570): toluene mass ratio of 1.0:3.0:100 (g / g / g), add to the three-necked flask in sequence Magnetic at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com