Preparation method of nickel-based catalyst for treating alkaline organic waste water

A technology of organic wastewater treatment and nickel-based catalysts, applied in the direction of physical/chemical process catalysts, water/sewage treatment, chemical instruments and methods, etc., can solve problems that have not yet been seen, and achieve low pH value, simple methods, and catalytic high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

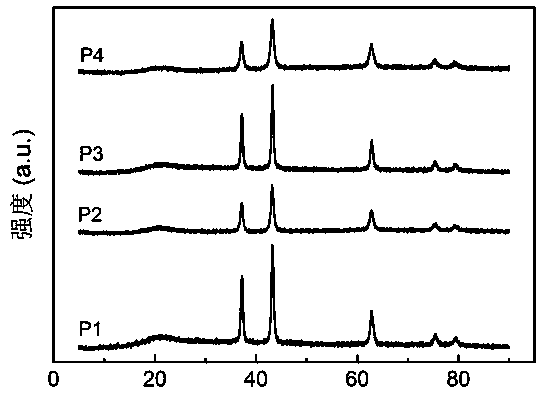

Image

Examples

Embodiment 1

[0024] A preparation method for a nickel-based catalyst for alkaline organic wastewater treatment, comprising the steps of:

[0025] Step 1), preparation of nickel-based catalyst precursor:

[0026] Nickel chloride hexahydrate (NiCl 2 ·6H 2 O) or nickel nitrate hexahydrate [Ni(NO 3 ) 2 ·6H 2 O] Dissolve in neutral deionized water at room temperature to prepare 0.1 mol / L nickel salt solution A, heat up to 90°C and keep the temperature stable; use a peristaltic pump to add ammonia water at a flow rate of 1.0mL / min to make the pH of solution A Stop after reaching 9.0, get solution B, continue to keep warm for 0.5 h;

[0027] Add sodium hydroxide solution to solution B through a peristaltic pump, stir well, the molar ratio of sodium hydroxide to nickel salt is 2.1:1, and the flow rate is 1.0 mL / min; after the addition of sodium hydroxide solution is completed, the system reacts 1.0 h;

[0028] After the reaction, the reaction system, that is, the resulting suspension, was c...

Embodiment 2

[0032] A preparation method for a nickel-based catalyst for alkaline organic wastewater treatment, comprising the steps of:

[0033] Step 1), preparation of nickel-based catalyst precursor:

[0034] Nickel chloride hexahydrate (NiCl 2 ·6H 2 O) or nickel nitrate hexahydrate [Ni(NO 3 ) 2 ·6H 2 O] Dissolve in neutral deionized water at room temperature to prepare 0.1 mol / L nickel salt solution A, heat up to 90°C and keep the temperature stable; use a peristaltic pump to add ammonia water at a flow rate of 1.0mL / min to make the pH of solution A Stop after reaching 10.0, get solution B, continue to keep warm for 0.5 h;

[0035] Add sodium hydroxide solution to step solution B through a peristaltic pump, stir well, the molar ratio of sodium hydroxide to nickel salt is 2.1:1, and the flow rate is 1.0 mL / min; after the addition of sodium hydroxide solution is completed, the system reacts again 1.0 h;

[0036] After the reaction, the reaction system, that is, the resulting suspe...

Embodiment 3

[0040] A preparation method for a nickel-based catalyst for alkaline organic wastewater treatment, comprising the steps of:

[0041] Step 1), preparation of nickel-based catalyst precursor:

[0042] Nickel chloride hexahydrate (NiCl 2 ·6H 2 O) or nickel nitrate hexahydrate [Ni(NO 3 ) 2 ·6H 2 O] Dissolve in neutral deionized water at room temperature to prepare 0.1 mol / L nickel salt solution A, heat up to 90°C and keep the temperature stable; use a peristaltic pump to add ammonia water at a flow rate of 1.0mL / min to make the pH of solution A Stop after reaching 10.0, get solution B, continue to keep warm for 0.5 h;

[0043] Add sodium hydroxide solution to solution B through a peristaltic pump, stir well, the molar ratio of sodium hydroxide to nickel salt is 2.1:1, and the flow rate is 1.0 mL / min; after the addition of sodium hydroxide solution is completed, the system reacts 1.0 h;

[0044] After the reaction, the reaction system, that is, the resulting suspension, was co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com