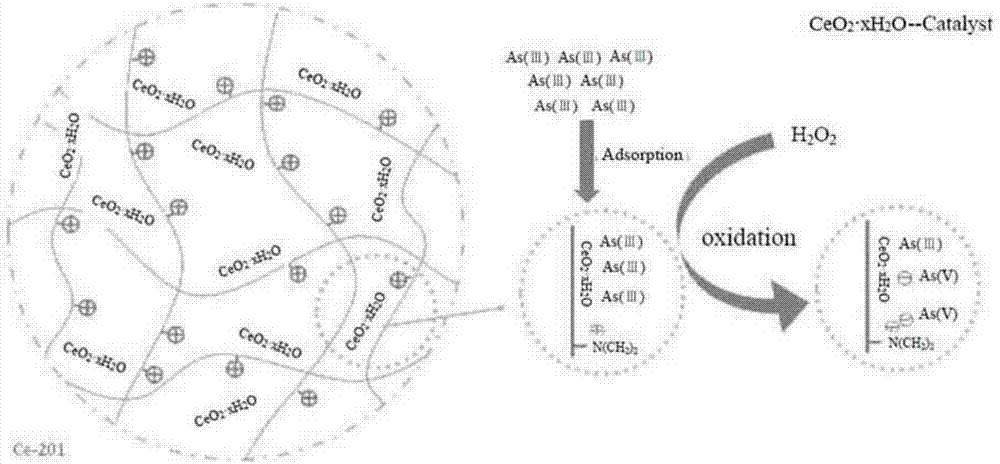

Preparation method of novel difunctional resin matrix nanocomposite material, composite material and method for removing trivalent arsenic in depth of water body

A technology of nanocomposite materials and bifunctional resins, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, water/sewage treatment, etc., can solve the problem of large dosage of oxidant and poor recycling effect Good, poor effect and other problems, to achieve the effect of improving the removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

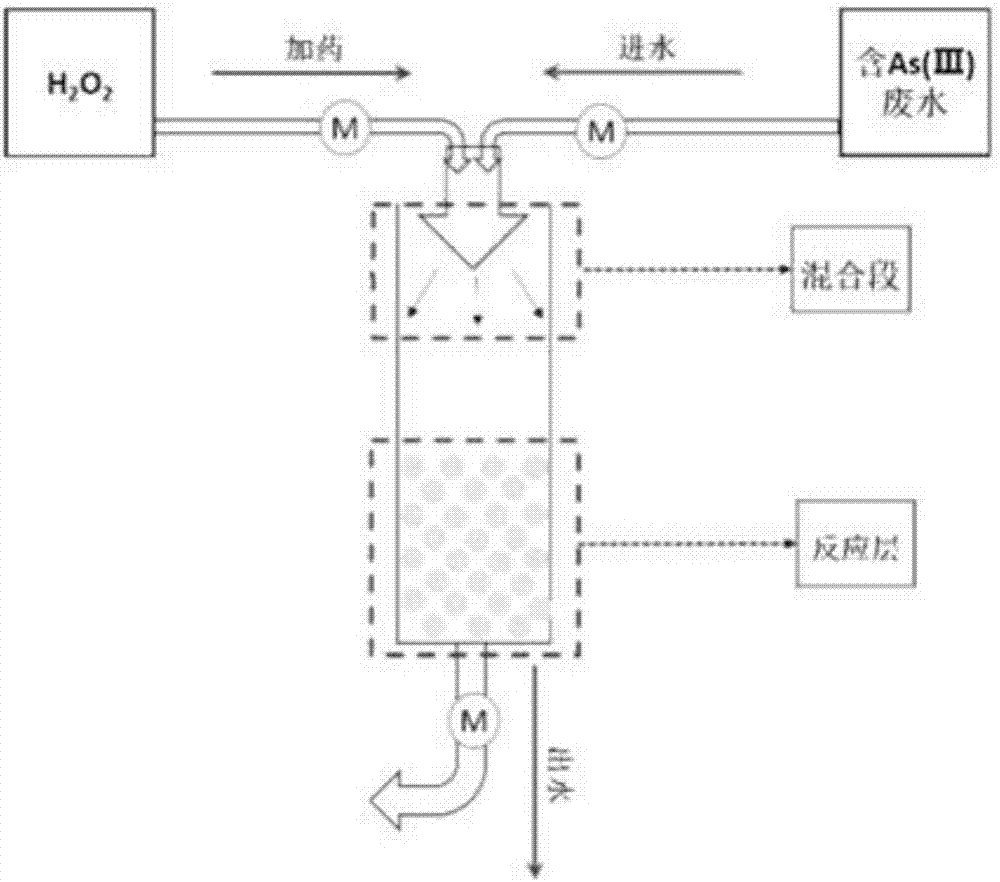

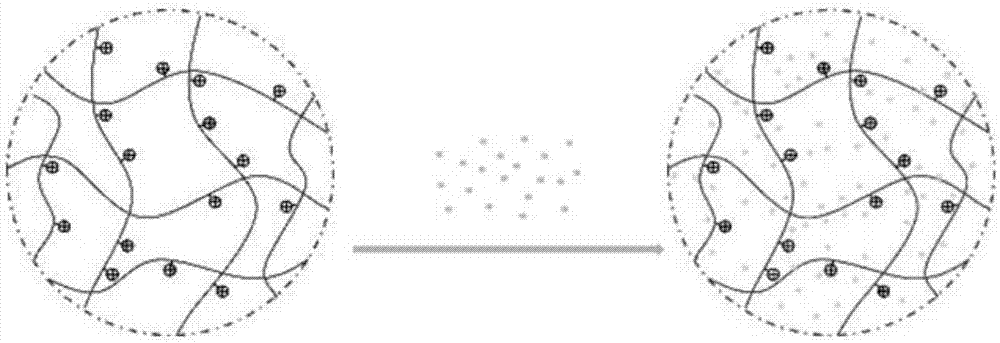

Method used

Image

Examples

Embodiment 1

[0046] In a 500mL beaker, add 9.87g of ceric ammonium nitrate, 20mL of concentrated nitric acid (65% by weight), 17g of sodium nitrate, fully dissolve and set the volume to 100mL; the concentration of ceric ammonium nitrate in this solution A is 0.18mol / L, HNO 3 The concentration is 3mol / L, NaNO 3 The concentration is 2mol / L.

[0047] Weigh 5g of NaOH into a 100mL volumetric flask, and dilute to get solution B;

[0048] Weigh 5g of NaCl into a 100mL volumetric flask, and make it to volume to obtain solution C;

[0049] Weigh 5g of D201 resin (produced by Hangzhou Zhengguang Resin Factory), add it into solution A first, then stir it at a speed of 200rpm for 8 hours; Stir at a speed of 200rpm for 8 hours. After the mixing, the resin is filtered out and air-dried naturally, and then added to solution C, and stirred at a speed of 200rpm for 8 hours. After the mixing is completed, the resin is filtered out and washed with a large amount of water until The pH was neutral, and aft...

Embodiment 2

[0051] In a 500mL beaker, add 16.45g of ammonium cerium nitrate, 25mL of concentrated nitric acid (65% by weight), and 26g of sodium nitrate, fully dissolve and set the volume to 100mL; the concentration of ammonium cerium nitrate in this solution A is 0.3mol / L, HNO 3 The concentration is 3.6 mol / L, NaNO 3 The concentration is 3mol / L.

[0052] Weigh 10g of NaOH into a 100mL volumetric flask, and dilute to get solution B;

[0053] Weigh 10g of NaCl into a 100mL volumetric flask, and dilute to get solution C;

[0054] Weigh 10g of D201 resin (produced by Hangzhou Zhengguang Resin Factory), add it to solution A first, then stir it at a speed of 250rpm for 9 hours; Stir at a speed of 250rpm for 9 hours. After the mixing, the resin is filtered out and air-dried naturally, and then added to solution C, and stirred at a speed of 250rpm for 9 hours. After the mixing is completed, the resin is filtered out and washed with a large amount of water until The pH was neutral, and after w...

Embodiment 3

[0056] In a 500mL beaker, add 29.6g ammonium cerium nitrate, 35mL concentrated nitric acid (65% by weight), 42.5g sodium nitrate, fully dissolve and settle to 100mL; the concentration of ammonium cerium nitrate in this solution A is 0.54mol / L, HNO 3 The concentration is 5 mol / L, NaNO 3The concentration is 5mol / L.

[0057] Weigh 15g of NaOH into a 100mL volumetric flask, and dilute to get solution B;

[0058] Weigh 15g of NaCl into a 100mL volumetric flask, and dilute to get solution C;

[0059] Weigh 15g of D201 resin (produced by Hangzhou Zhengguang Resin Factory), add it into solution A first, and then stir it at a speed of 250rpm for 10 hours; Stir at a speed of 300rpm for 10 hours. After the mixing, the resin is filtered out and air-dried naturally, and then added to solution C, and stirred at a speed of 300rpm for 10 hours. After the mixing is completed, the resin is filtered out and washed with a large amount of water until The pH is neutral, and after washing with 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

| Loading capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com