Preparation method and application of magnetic silicon-coated yeast grafted polyethyleneimine biological composite material

A polyethyleneimine, composite material technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., to achieve the effect of enhancing adsorption performance, improving yield, magnetic stability performance and thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

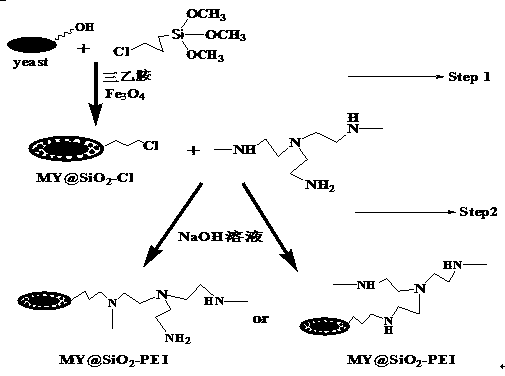

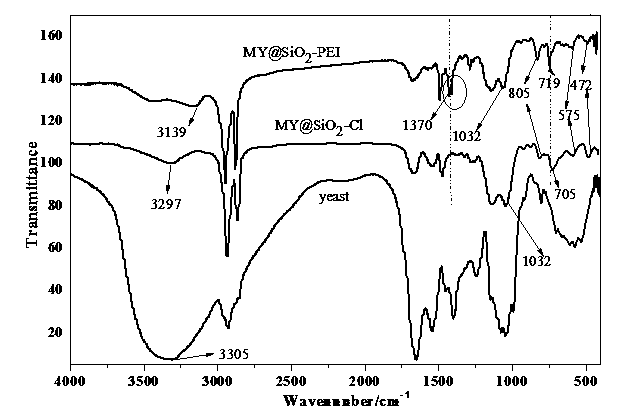

Method used

Image

Examples

Embodiment 1

[0039] (1) MYSiO 2 Preparation of -Cl:

[0040] Weigh 0.5g of yeast, activate it in 60 mL of normal saline (0.9% sodium chloride solution) at 35°C for 60 minutes; centrifuge to collect the thick yeast suspension and mix with 0.1g Fe 3 o 4 The nanoparticles were mixed and ultrasonicated for 5 minutes; the mixture was poured into a 250 ml three-neck flask, and 100 ml of toluene liquid was added under the condition of mechanical stirring; the mixed toluene solution was ventilated with nitrogen, and 1 ml of triethylamine and 3 ml of 3-chloropropyltrimethoxysilane; then react at 85°C for 9 hours, collect and separate the product with a permanent magnet, and wash it repeatedly with acetone, methanol and deionized water in sequence, and dry the product at 40°C.

[0041] (2) MYSiO 2 - Preparation of PEI:

[0042] Weigh 0.3g of the magnetic yeast-coated silicon product and place it in a 100ml three-neck flask; pipette 0.6g of polyethyleneimine and dissolve it in 60ml of deionized w...

Embodiment 2

[0049] (1) MYSiO 2 Preparation of -Cl:

[0050] Weigh 0.5g of yeast and activate it in 50 mL of normal saline (0.8% sodium chloride solution) at 35°C for 50 minutes; centrifuge to collect about thick yeast suspension and mix with 0.05g Fe 3 o 4 Nanoparticles were mixed and ultrasonicated for 1 minute; the mixture was poured into a 250 mL three-necked flask, and 80 mL of toluene liquid was added under mechanical stirring; the mixed toluene solution was ventilated with nitrogen, and after 10 minutes, 0.8 mL of triethylamine and 2 mL of 3-Chloropropyltrimethoxysilane; then react at 80°C for 10 hours, collect and separate the product with a permanent magnet, and wash it repeatedly with acetone, methanol and deionized water in sequence, and dry the product at 40°C.

[0051] (2) MYSiO 2 - Preparation of PEI:

[0052] Weigh 0.2 g of the magnetic yeast-coated silicon product and place it in a 100 ml three-neck flask; pipette 0.3 g of polyethyleneimine and dissolve it in 60 ml of d...

Embodiment 3

[0054] (1) MYSiO 2 Preparation of -Cl:

[0055] Weigh 0.5g of yeast and activate it in 70 mL of normal saline (1% sodium chloride solution) for 70 minutes at 35°C; centrifuge to collect about thick yeast suspension and mix with 0.15 g Fe 3 o 4 Nanoparticles were mixed and ultrasonicated for 10 minutes; the mixture was poured into a 250 mL three-neck flask, and 120 mL of toluene liquid was added under mechanical stirring; the mixed toluene solution was ventilated with nitrogen, and after 20 minutes, 1.2 mL of triethylamine and 4 mL of 3-Chloropropyltrimethoxysilane; then react at 90°C for 11 hours, collect and separate the product with a permanent magnet, and wash it repeatedly with acetone, methanol and deionized water in sequence, and dry the product at 40°C.

[0056] (2) MYSiO 2 - Preparation of PEI:

[0057] Weigh 0.4 g of the magnetic yeast-coated silicon product and place it in a 100 ml three-neck flask; pipette 1.2 g of polyethyleneimine and dissolve it in 60 ml of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com