High-selectivity cauliflower-shaped lithium ion absorbent, and preparation method and application

A high-selectivity, lithium-ion technology, applied in the direction of selective adsorption, ion exchange, ion exchange regeneration, etc., can solve the problems of low selectivity, no specific recognition ability, etc., to achieve short process, good stability and regeneration cycle. , the effect of good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Dissolve 12-crown-4-ether (20mg) and lithium perchlorate (20mg) in 50mL of acetonitrile solution, mix thoroughly; then add acrylamide (60mg), stir slowly at room temperature for 10min; then add N'N -Methylenebisacrylamide (90mg) and azobisisobutyronitrile (20mg), through N 2 10min, placed in a water bath shaker at 60°C for 24h; finally, the centrifuged product was washed with methanol for more than 3 times, after drying, pickled in 0.5mol / L HCl solution to remove lithium ions, and dried Obtain the imprinted polymer.

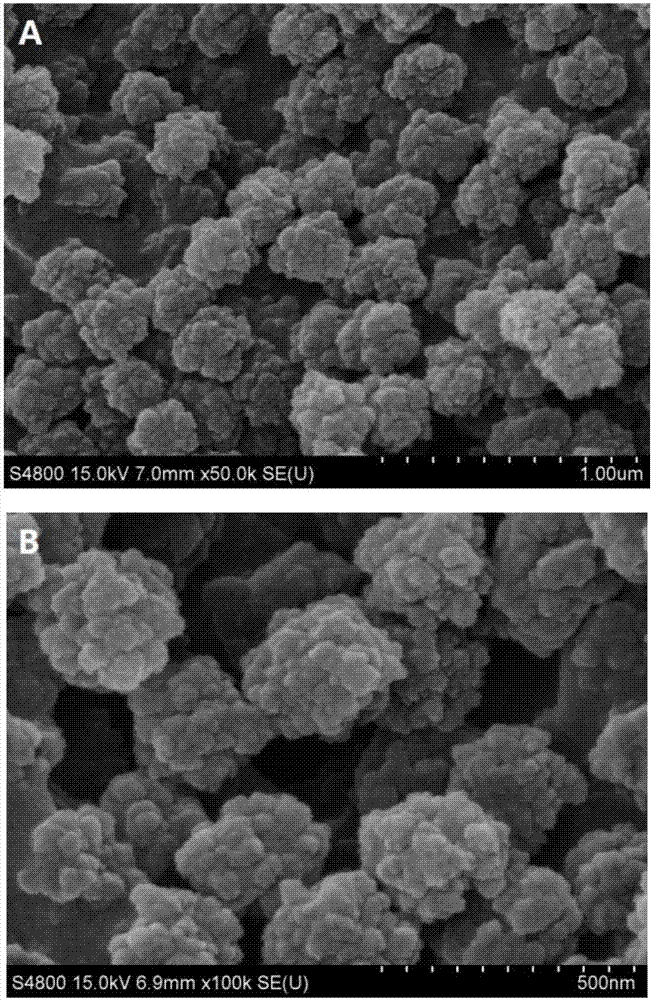

[0027] figure 1 is the scanning electron microscope image of the adsorbent, where (A) is a low-magnification scanning electron microscope image, and (B) is a high-magnification scanning electron microscope image. It can be seen from the figure that the shape of the polymer is like a cauliflower, and the shape is relatively uniform .

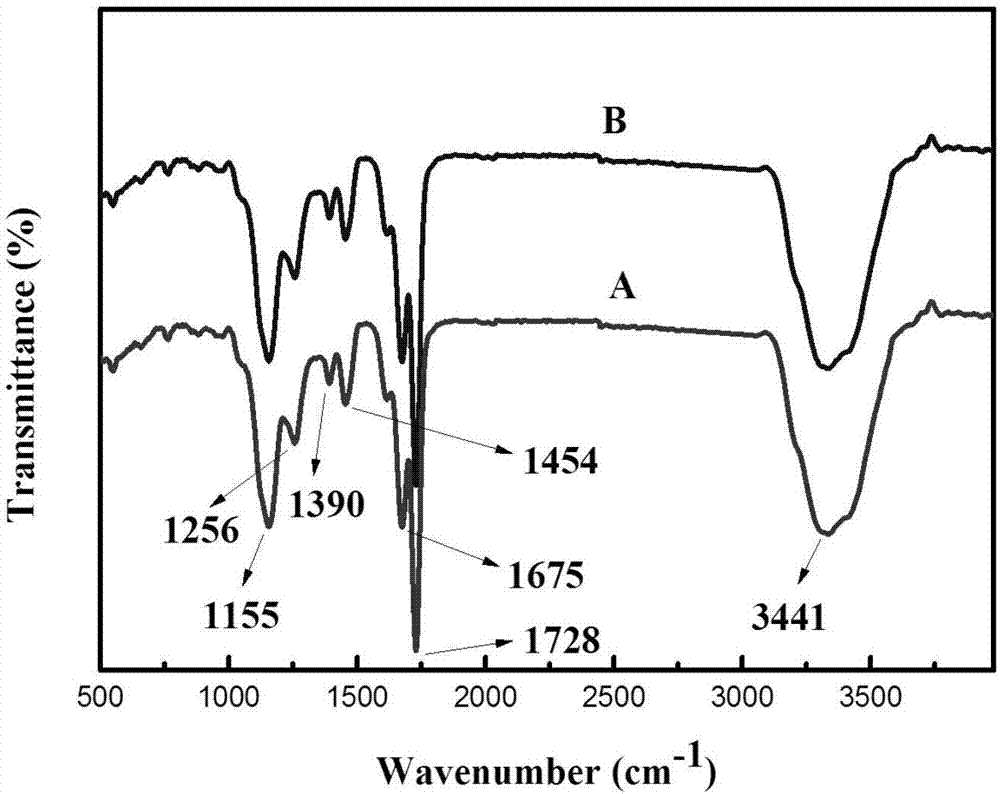

[0028] figure 2 is the IR diagram of the adsorbent, from which the distribution of peaks can be analyzed, and the pol...

Embodiment 2

[0033] Dissolve 12-crown-4-ether (20mg) and lithium perchlorate (20mg) in 50mL of acetonitrile solution, mix thoroughly; then add acrylamide (40mg), stir slowly at room temperature for 10min; then add N'N- Methylenebisacrylamide (80mg) and azobisisobutyronitrile (20mg), through N 2 15min, placed in a water bath shaker at 60°C for 24h; finally, the centrifuged product was washed with methanol for more than 3 times, after drying, pickled in 1.0mol / L HCl solution to remove lithium ions, and dried Obtain the imprinted polymer.

Embodiment 3

[0035] Dissolve 12-crown-4-ether (30mg) and lithium perchlorate (20mg) in 50mL of acetonitrile solution, mix thoroughly; then add acrylamide (60mg), stir slowly at room temperature for 15min; then add N'N- Methylenebisacrylamide (120mg) and azobisisobutyronitrile (20mg), through N 2 10min, placed in a water bath shaker at 60°C for 24h; finally, the centrifuged product was washed with methanol for more than 3 times, after drying, pickled in 2.0mol / L HCl solution to remove lithium ions, and dried Obtain the imprinted polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com