Hot air vulcanization process of multi-layer winding rubber straight tube with polyester film as coating

A technology of hot air vulcanization and polyester film, which is applied to tubular articles, other household appliances, household appliances, etc., can solve the problems of high energy consumption and unstable product quality of multi-layer winding rubber pipes, and achieves resource saving and smooth surface. Beautiful, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

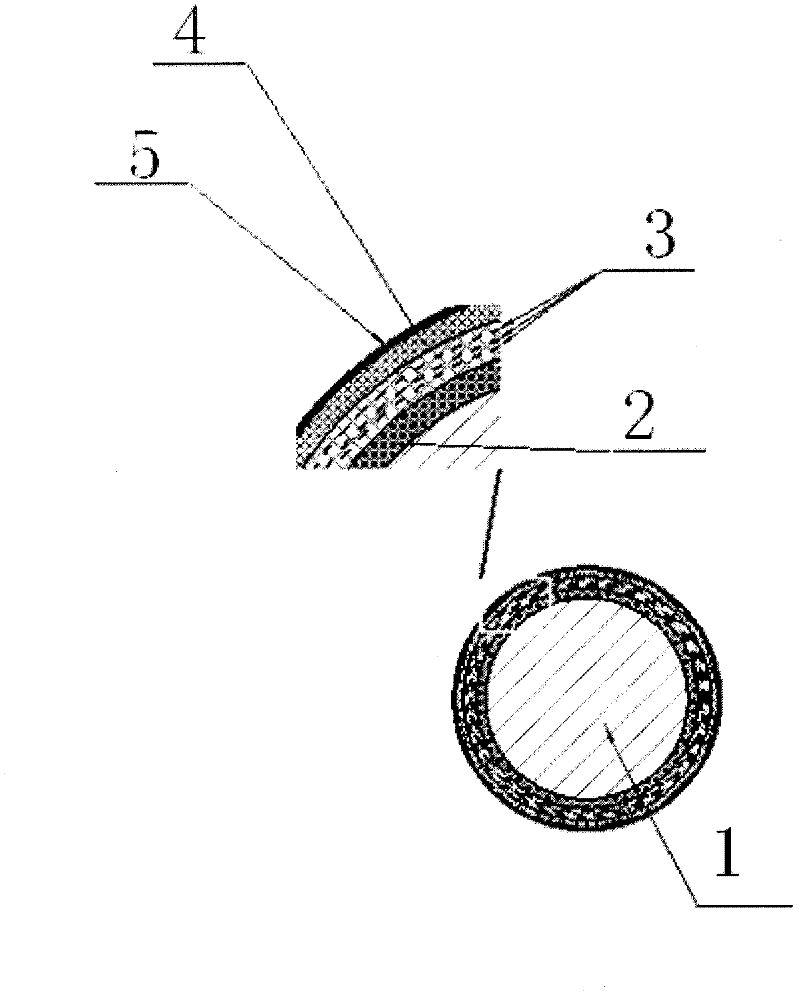

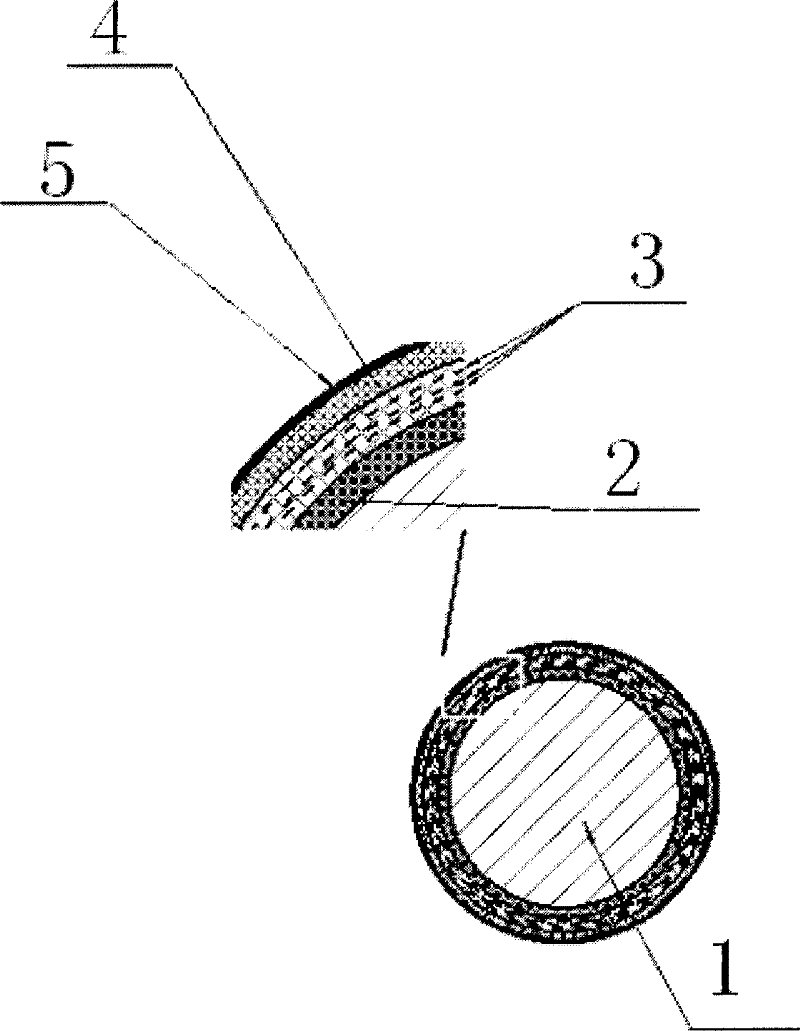

[0016] will now refer to figure 1 Preferred embodiments of the present invention will be described in detail.

[0017] see figure 1 ,in figure 1 The upper left part is an enlarged cross-sectional view of a multi-layer wound rubber straight pipe with a polyester film 5 as a coating layer. A hot air vulcanization process for a multi-layer wound rubber straight pipe with a polyester film 5 as a coating layer includes the following step:

[0018] I. Form a rubber tube of corresponding size and specification on the hard mold core 1, and fix the hard mold core 1 and the rubber tube on the machine;

[0019] II. Coating the pre-prepared polyester film 5 from one end of the rubber tube and the hard mold core 1;

[0020] III. Put the coated rubber tube and the hard mold core 1 together into a hot air vulcanization tank for vulcanization. No need to inject pressure into the vulcanization tank, that is, vulcanize under normal pressure conditions;

[0021] IV, vulcanization is complet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com