Preparation method of magnetic composite catalyst Ag/HNTs/Fe3O4

A composite catalyst and magnetic technology, used in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of slow oxidation of magnetic carriers and air, and achieve Reuse is significant, the effect is significant, the effect of reducing direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

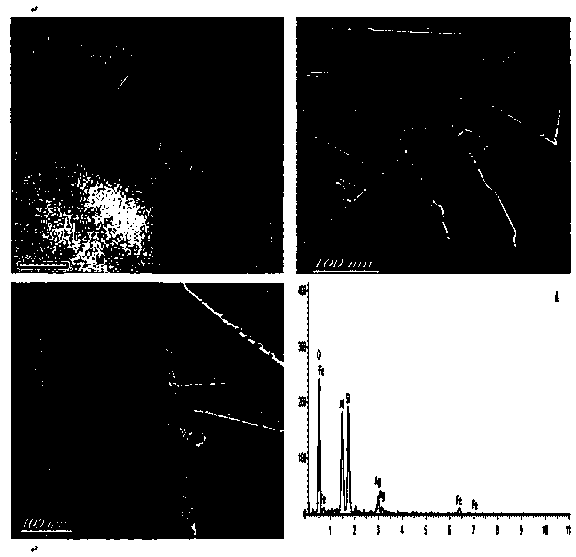

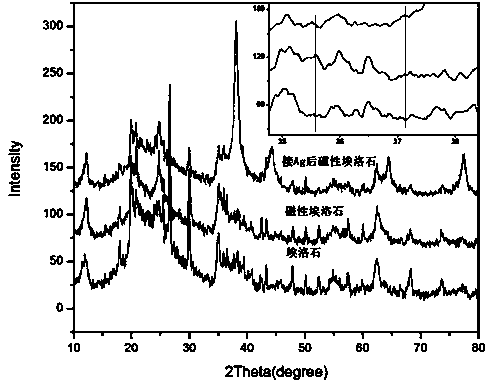

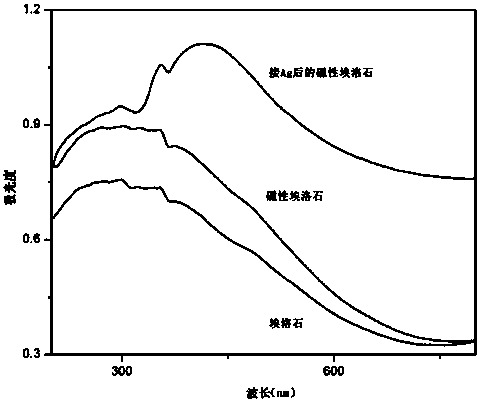

Image

Examples

Embodiment 1

[0029] 1. A magnetic composite catalyst Ag / HNTs / Fe 3 o 4 The preparation method is characterized in that it is carried out according to the following steps:

[0030] (1) Halloysite nanotubes (HNTs) activation method

[0031] Blocky halloysite nanotubes were ground and pulverized, 50 mL of concentrated nitric acid was placed in 200 mL of distilled water, 20 g of ground halloysite nanotubes were placed in the above solution, and refluxed at 75 °C for 12 h to obtain The product was washed with double distilled water to neutrality, and dried at 60 °C to constant weight; finally, the dried halloysite nanotubes were calcined in a calciner at 200 °C for 2 h.

[0032] (2) Magnetic halloysite nanotube composites (HNTs / Fe 3 o 4 ) preparation

[0033] 0.66 g of activated HNTs and 0.33 g of ferric nitrate nonahydrate were dissolved in 25 g of absolute ethanol and dispersed ultrasonically for 60 minutes; then the mixture was evaporated to constant weight in a water bath at 60 °C; ...

Embodiment 2

[0048] 1. A magnetic composite catalyst Ag / HNTs / Fe 3 o 4 The preparation method is characterized in that it is carried out according to the following steps:

[0049] (1) Halloysite nanotubes (HNTs) activation method

[0050] The massive halloysite nanotubes were ground and pulverized, 50 mL of concentrated nitric acid was placed in 212.5 mL of distilled water, 19 g of ground halloysite nanotubes were placed in the above solution, and refluxed at 80 °C for 12.5 h, the obtained The product was washed with double distilled water to neutrality, and dried at 60 °C to constant weight; finally, the dried halloysite nanotubes were calcined in a calciner at 225 °C for 2.25 h.

[0051] (2) Magnetic halloysite nanotube composites (HNTs / Fe 3 o 4 ) preparation

[0052] 0.71 g of activated HNTs and 0.38 g of ferric nitrate nonahydrate were dissolved in 27.5 g of absolute ethanol and dispersed ultrasonically for 60 min; then the mixture was evaporated to constant weight in a water b...

Embodiment 3

[0060] 1. A magnetic composite catalyst Ag / HNTs / Fe 3 o 4 The preparation method is characterized in that it is carried out according to the following steps:

[0061] (1) Halloysite nanotubes (HNTs) activation method

[0062] Blocky halloysite nanotubes were ground and pulverized, 50 mL of concentrated nitric acid was placed in 225 mL of distilled water, 18 g of ground halloysite nanotubes were placed in the above solution, and refluxed at 80 °C for 13 h to obtain The product was washed with double distilled water to neutrality, and dried at 60 °C to constant weight; finally, the dried halloysite nanotubes were calcined in a calciner at 250 °C for 2.5 h.

[0063] (2) Magnetic halloysite nanotube composites (HNTs / Fe 3 o 4 ) preparation

[0064] 0.76 g of activated HNTs and 0.40 g of ferric nitrate nonahydrate were dissolved in 30 g of absolute ethanol and dispersed ultrasonically for 60 min; then the mixture was evaporated to constant weight in a water bath at 60 °C. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com