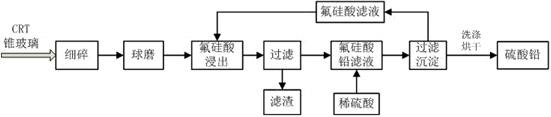

Method for extracting lead from waste CRT (Cathode Ray Tube) cone glass

A technology of conical glass and broken glass, which is applied in the field of lead extraction, can solve problems such as difficult application and popularization, complex extraction process, and strict equipment conditions, and achieve good industrialization promotion and application value, reduce environmental pollution, and reduce environmental hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Remove the inner and outer surface coatings of the waste CRT cone glass and dry them. After coarse crushing and fine crushing to 100-200 mesh powder, it is activated by mixing and ball milling with a certain material-ball ratio. The ball milling conditions were set as a material-ball ratio of 1:2, agate balls with a ball diameter of 10 mm, 580 rpm / min, and a ball milling time of 8 h. Finally, the glass powder can be ground to a fineness of 1-10 μm. The activated cone glass powder was dried in a vacuum oven at 105°C for later use. Through XRF analysis, its chemical composition is as follows:

[0026] chemical components Na 2 o al 2 o 3 SiO 2 K 2 o CaO SrO BaO PbO Content (wt%) 7.38 3.27 50.8 8.32 3.89 0.59 0.65 21.7

[0027] Take 20.005g of conical glass powder and 200ml of 1mol / L fluosilicic acid, put them into a Erlenmeyer flask, seal with a silica gel stopper to prevent volatilization of the fluosilicic acid solution...

Embodiment 2

[0031] Still take some of the 100-200 mesh cone glass powder of the above reaction.

[0032] The ball milling conditions were set as material-ball ratio 1:2, ratio of 10 mm agate balls to 3 mm agate balls 1:1, rotational speed 580 rpm / min, ball milling time 12 h. After ball milling, put the ground cone glass powder into a drying oven at 105°C to dry for later use.

[0033] Take 20.008g of conical glass powder and 200ml of 1mol / l fluosilicic acid, put them into an Erlenmeyer flask, heat in a water bath to 90°C, stir at 500 rpm / min, and react for 12 hours.

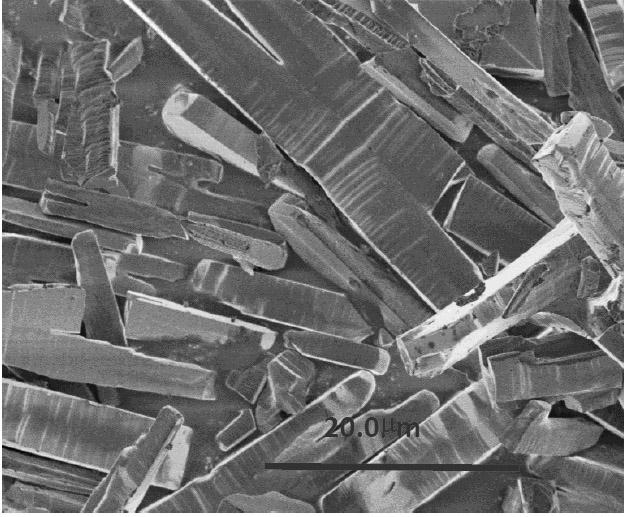

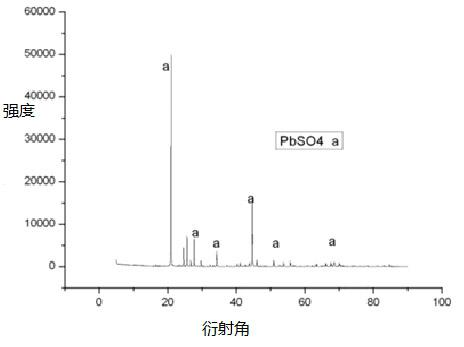

[0034] After the reaction is complete, vacuum filter the solution after it has cooled down. The leach solution is slowly added to the above-mentioned beaker containing the leach solution with 0.5 mol / L dilute sulfuric acid. After the reaction is complete, let it stand for 1-2 hours. Pour the solution and precipitate in the beaker into a vacuum filter for suction filtration, and repeatedly wash the filter cake with deionized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com